A kind of heat-strength damage-tolerant titanium alloy and preparation method thereof

A damage tolerance and titanium alloy technology, applied in the field of alloys, can solve the problems of limiting the application of damage tolerance titanium alloys, and achieve the effects of good thermal processing processability, high room temperature strength, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

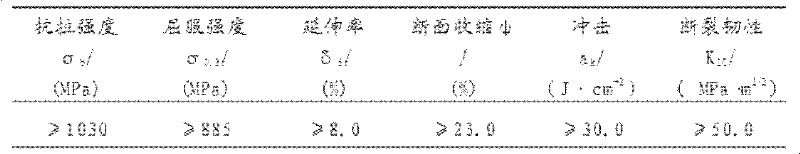

Image

Examples

Embodiment 1

[0031] Preparation of 300 kg grade Ti-6.5Al-3.5Mo-2Nb-2Sn-2Zr-0.2Si titanium alloy:

[0032] (1) Ingredients and electrode pressing:

[0033] According to the nominal composition Ti-6.5Al-3.5Mo-2Nb-2Sn-2Zr-0.2Si (ie 6.5% Al; 3.5% Mo; 2% Nb; 2% Sn; 2% Zr; 0.2% Si ; The rest is Ti), select first-grade small particle sponge titanium, Al-Mo master alloy, Ti-Nb master alloy, Ti-Sn master alloy, Ti-Si master alloy, pure metal Zr, mix 300Kg, press with press Form a block electrode with a single weight of 10Kg.

[0034] (2) Electrode preparation:

[0035] Argon shielded plasma welding machine is used to weld the pressed electrode blocks into long strip electrodes.

[0036] (3) Prepare an ingot:

[0037] The electrode prepared in the previous step was used as the consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting current was 5KA, and the melting voltage was controlled at 26V.

[0038] (4) prepare secondary ingot:

[003...

Embodiment 2

[0052] Preparation of 2000 kg grade Ti-6.5Al-3.5Mo-2Nb-2Sn-2Zr-0.2Si titanium alloy:

[0053] (1) Ingredients and electrode pressing:

[0054] According to the nominal composition Ti-6.5Al-3.5Mo-2Nb-2Sn-2Zr-0.2Si, select first-grade small particle sponge titanium, Al-Mo master alloy, Al-Nb master alloy, Ti-Sn master alloy, Ti-Si master alloy Alloy, pure metal Zr, mixing 2000Kg (divided into 20 times), pressed with a press to form a block electrode with a single weight of 50Kg.

[0055] (2) Electrode preparation:

[0056] Argon shielded plasma welding machine is used to weld the pressed electrode blocks into long strip electrodes.

[0057] (3) Prepare an ingot:

[0058] Use the electrode prepared in the previous step as the consumable electrode to melt in a vacuum consumable electric arc furnace to obtain a primary ingot, the melting current is 6KA, and the melting voltage is controlled at 35V.

[0059] (4) prepare secondary ingot:

[0060] The primary ingot was inverted a...

Embodiment 3

[0073] In this embodiment, the mass percentage composition of the heat-strength damage-tolerant titanium alloy is as follows:

[0074] 5.8% Al; 2.8% Mo; 1.6% Nb; 1.6% Sn; 1.6% Zr; 0.15% Si; the rest is Ti.

[0075] 1) Mix the materials according to the content of the components, and use a press and a mold to press into an electrode block.

[0076] 2) Use vacuum plasma welding, argon shielded plasma welding or vacuum electron beam welding to quickly assemble and weld the electrodes pressed in step 1) into strip electrodes.

[0077] 3) Using the strip-shaped electrode prepared in step 2) as a consumable electrode to smelt in a vacuum consumable electric arc furnace to obtain a primary ingot; the smelting current is 5KA, and the smelting voltage is controlled at 26V.

[0078] 4) Invert the primary ingot and use it as a consumable electrode for secondary melting in a vacuum consumable electric arc furnace to obtain a secondary ingot; the melting current is 6KA, and the melting vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com