Application of quinolone derivatives as OLED emission materials in organic electroluminescent devices

A technology for electroluminescent devices and emitting materials, which is applied in the application of luminescent materials, electro-solid devices, gas discharge lamps, etc., and can solve the problem of low fluorescence quantum efficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

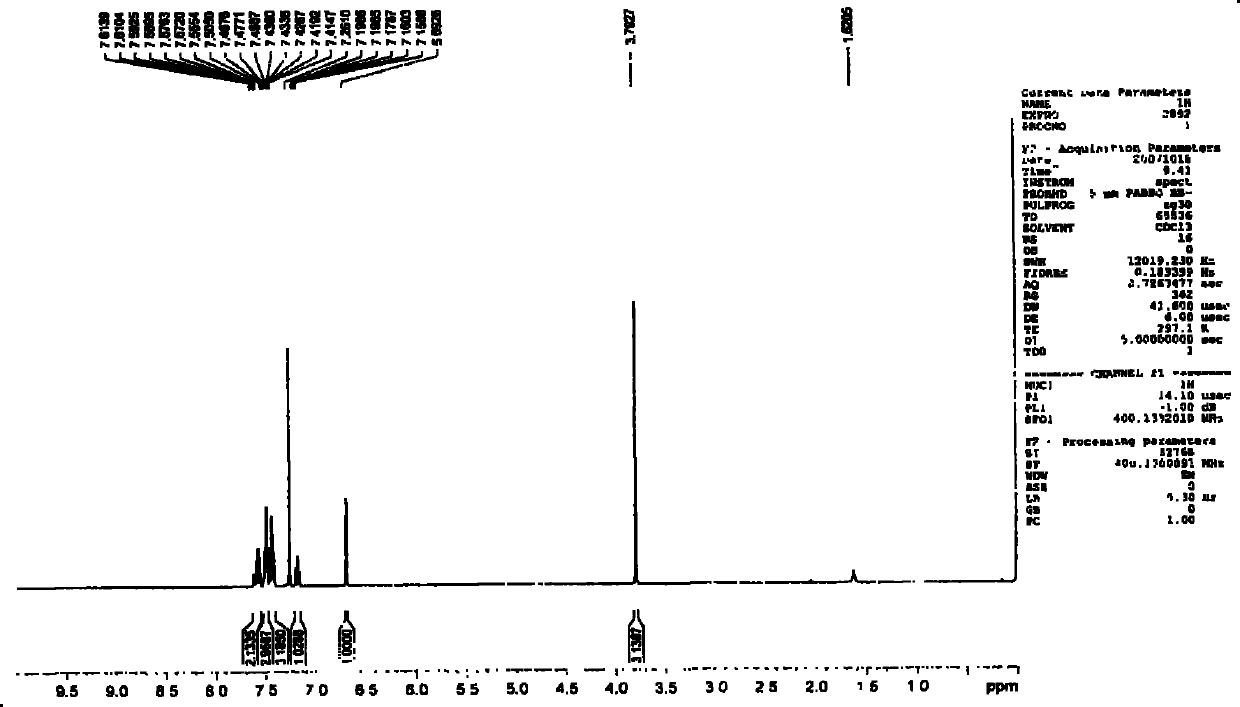

[0073] Embodiment 1,1-methyl-3, the preparation of 4-diphenylquinolin-2 (1H)-ketone (Q1)

[0074]

[0075] The first step: take 1-methyl-4-phenylquinolin-2(1H)-one with a molar ratio of 1:1, and N-bromosuccinimide as raw materials, and dissolve the above-mentioned raw materials in N, N-dimethylformamide was reacted with stirring at room temperature for 10 hours, and a large amount of solid was precipitated by adding water, which was washed and dried to obtain the corresponding bromide with a yield of 80%.

[0076] The second step: under the protection of nitrogen, the bromide obtained in the first step and phenylboronic acid (molar ratio is 1: 1) are dropped into two-necked flasks, and a catalytic amount of tetrakis (triphenyl) phosphine palladium) and mixed solvent ( Sodium carbonate solution (2mol / L):toluene:ethanol=1:4:4), keep the temperature at 90-100°C, stir for 24 hours, extract with ether, and the product is subjected to column chromatography (eluent is petroleum et...

Embodiment 2

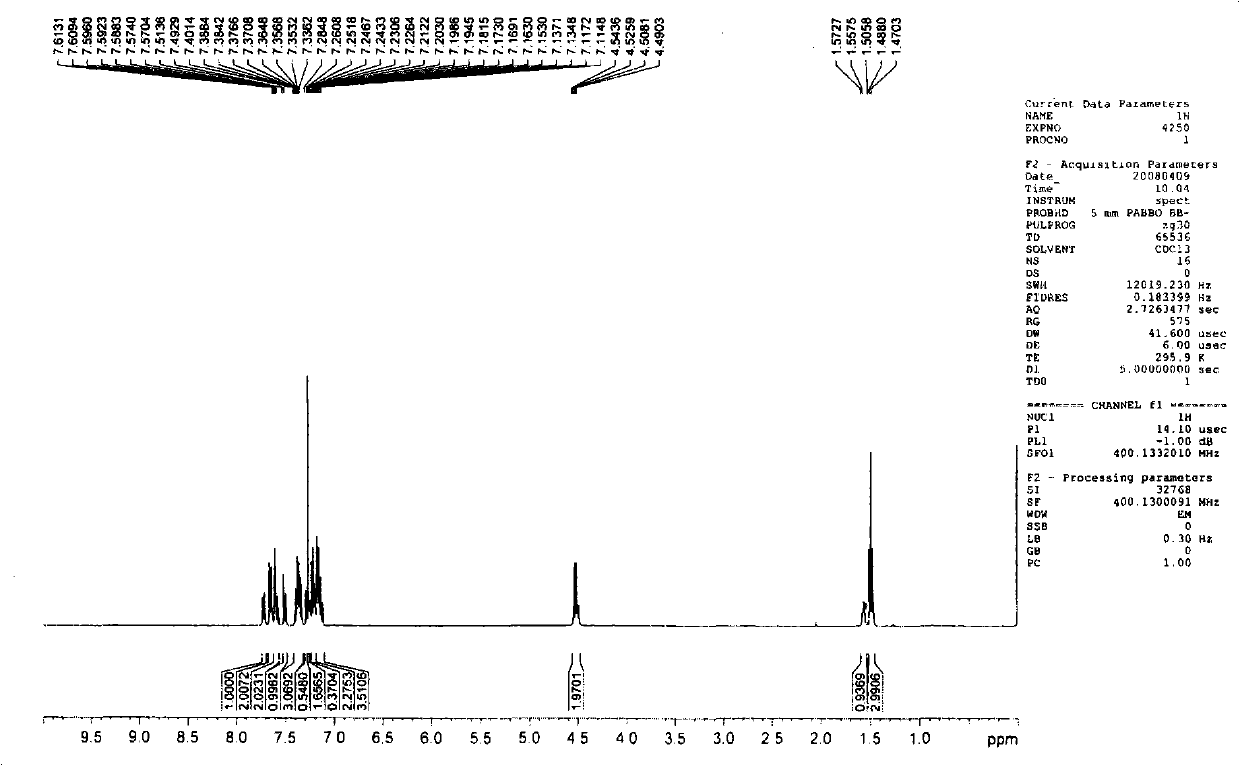

[0087] Embodiment 2, the preparation of 1-methyl-3-(2-naphthyl)-4-phenylquinolin-2(1H)-one (Q2)

[0088]

[0089] The first step: take 1-ethyl-4-phenylquinolin-2(1H)-one with a molar ratio of 1:1, and N-bromosuccinimide as raw materials, dissolve the above raw materials in N, N-dimethylformamide was stirred at room temperature for 10 hours, and a large amount of solid was precipitated by adding water. The solid was washed and dried to obtain the corresponding bromide with a yield of 80%.

[0090]The second step: under the protection of nitrogen, put the product obtained in the first step and 2-naphthylboronic acid (the molar ratio is 1:1) into a two-neck flask, add a catalytic amount of tetrakis (triphenyl) phosphine palladium) and a mixed solvent (sodium carbonate solution (2mol / L):toluene:ethanol=1:4:4), keep the temperature at 90-100°C, stir for 24 hours, extract with ether, and the product is subjected to column chromatography (eluent is petroleum ether / ethyl acetate E...

Embodiment 3

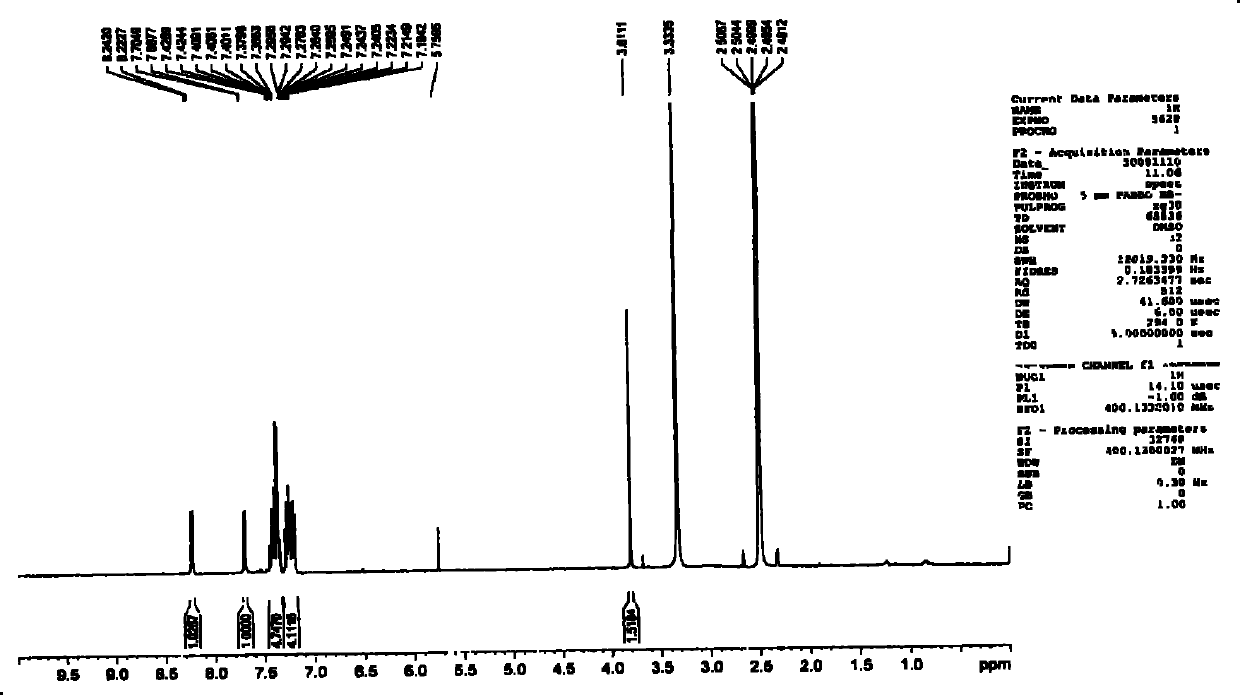

[0100] Embodiment 3, the preparation of 1-methyl-3-(4-(9-carbazolyl)phenyl)-4-phenylquinolin-2(1H)-one (Q3)

[0101]

[0102] The first step: take 1-methyl-4-phenylquinolin-2(1H)-one with a molar ratio of 1:1, and N-bromosuccinimide as raw materials, and dissolve the above-mentioned raw materials in N, N-dimethylformamide was stirred at room temperature for 10 hours, and a large amount of solid was precipitated by adding water. The solid was washed and dried to obtain the corresponding bromide with a yield of 80%.

[0103] The second step: under the protection of nitrogen, put the product obtained in the first step and 4-(9-carbazolyl)phenylboronic acid (1:1 in molar ratio) into a two-necked bottle, and add a catalytic amount of tetrakis(triphenyl) ) phosphine palladium) and mixed solvent (sodium carbonate solution: toluene: ethanol = 1: 4: 4), keep the temperature at 90-100 ° C, stir for 24 hours, extract with ether, and the product is subjected to column chromatography (e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com