Permanent magnet synchronous machine (PMSM) possessing assembled magnetic effect

A permanent magnet synchronous motor, the technology of action, applied in the synchronous motor with static armature and rotating magnet, magnetic circuit static parts, magnetic circuit rotating parts and other directions, can solve the requirements of distributed winding end length and rotating shaft material High, large magnetic flux leakage on the shaft side, etc., to achieve the effect of low probability of inter-turn short circuit fault, less copper consumption, and reduction of magnetic flux leakage at the end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be explained in detail below in conjunction with the accompanying drawings.

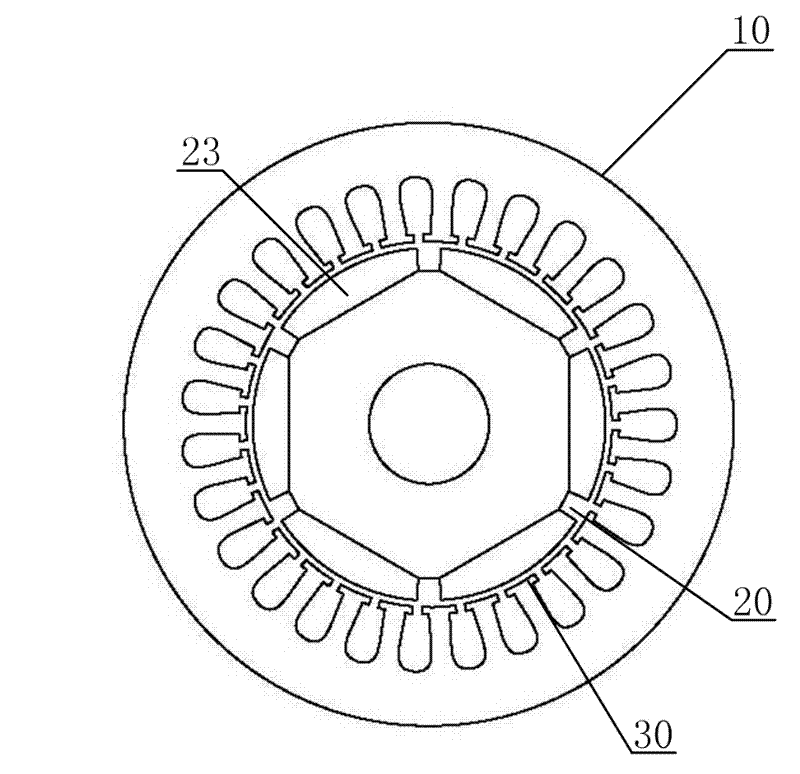

[0034] Please refer to Figure 5 , the present invention is a permanent magnet synchronous motor with magnetism gathering effect, which adopts a built-in tangential rotor magnetic circuit structure, including a stator 10 and a rotor 20, an air gap 30 is provided between the stator 10 and the rotor 20, and the stator 10 includes a stator core 11 and stator winding 12, the rotor 20 includes a rotor core 21, a rotating shaft 22 and a permanent magnet 23.

[0035] Please continue to refer Figure 5 , the stator 10 has nine slots, and the corresponding stator winding 12 can be further set as a fractional slot winding, which can increase the equivalent number of slots per pole and phase, thereby weakening the influence of higher harmonics; on the other hand, The significance of using the fractional slot winding is that it can effectively weaken th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com