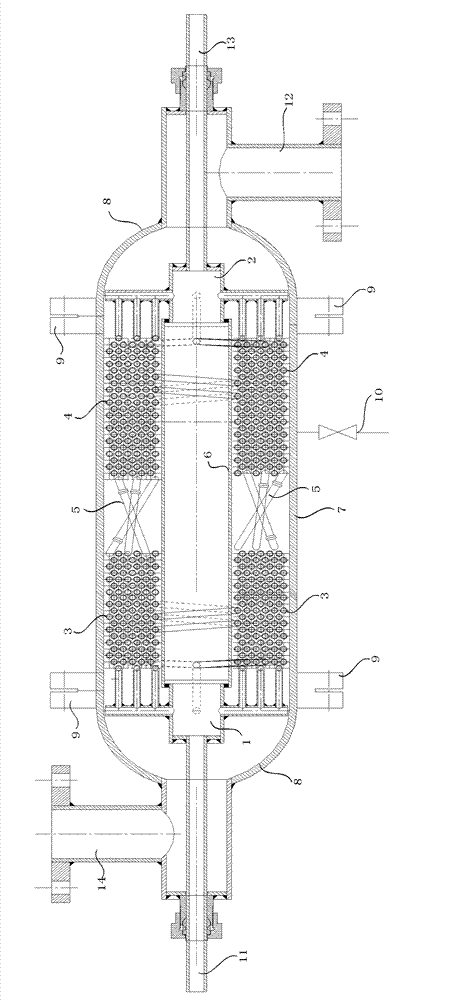

Shell and tube heat exchanger

A technology of shell-and-tube heat exchangers and coils, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., and can solve problems such as low heat exchange efficiency, bulky volume, and bulky heat exchange equipment , to achieve the effect of improved heat transfer efficiency, broad application prospects and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

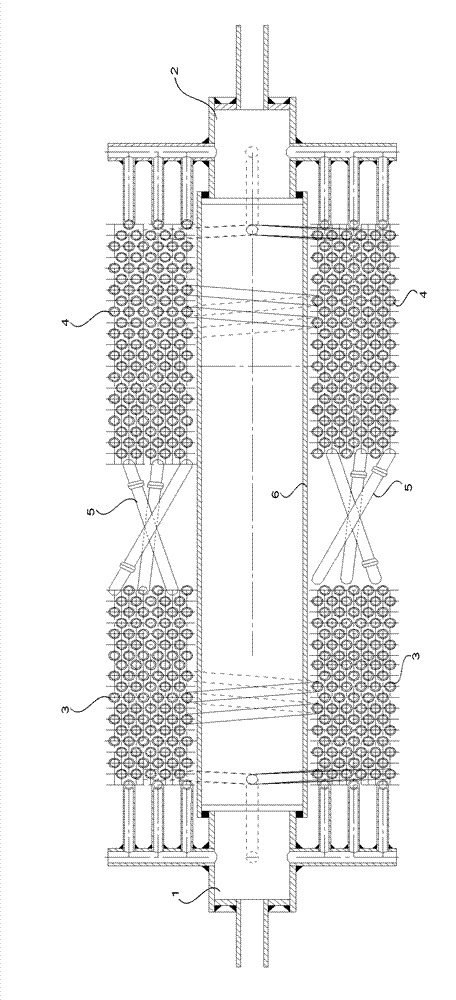

[0033] Take the 6+5 row coil tube bundle as an example.

[0034] Such as Figure 5 As shown, the coiled pipes are divided into even rows and odd rows (that is, 6 rows and 5 rows, 11 rows in total), and are coiled alternately on the support pipe 6 in the middle. ( Figure 5 a in represents the distance between the support pipe 6 and the innermost coil)

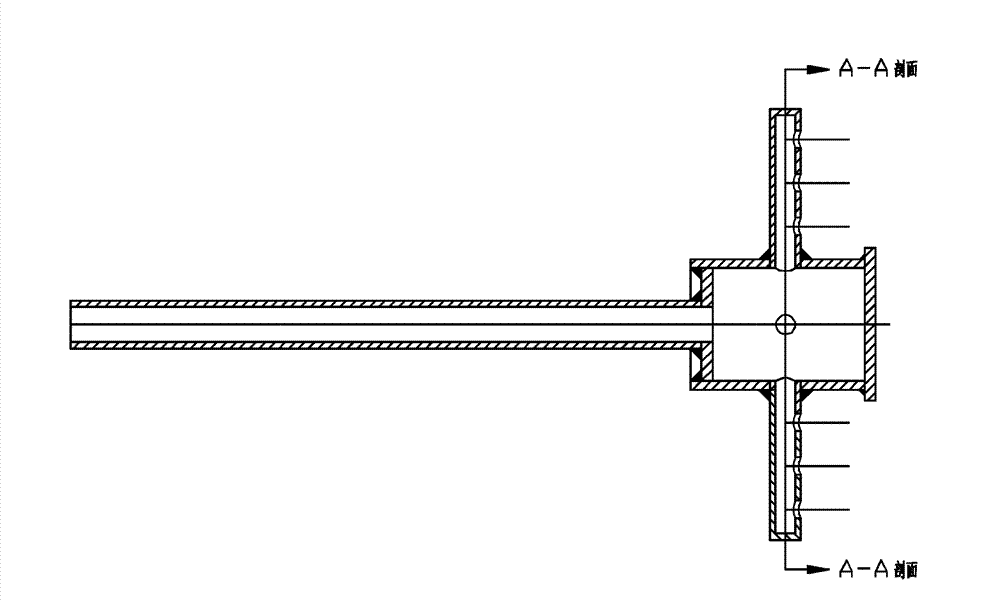

[0035] Inlet mixing chamber 1, outlet mixing chamber 2 such as image 3 , Figure 4As shown, for the flow in the pipe, a plurality of shunt pipes are arranged on the inlet mixing chamber 1 and the outlet mixing chamber 2, and circular ports are arranged on these shunt pipes to connect with the coil phase tube bundles respectively. image 3 In the example, four shunt pipes are set in the four directions of the inlet mixing chamber 1 and the outlet mixing chamber 2 respectively, as shown in Figure 4 As shown, three of the shunt pipes are provided with 3 circular ports, and the remaining one of the shunt pipes is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com