Method for preparing high purity oxygen by oxygen-nitrogen liquefying apparatus

A liquefaction device, high-purity oxygen technology, applied in liquefaction, refrigeration, liquefaction, solidification and other directions, can solve the problems of large investment, limited production and refrigeration capacity, etc., to achieve the effect of efficient process, lower production threshold, simple and effective.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

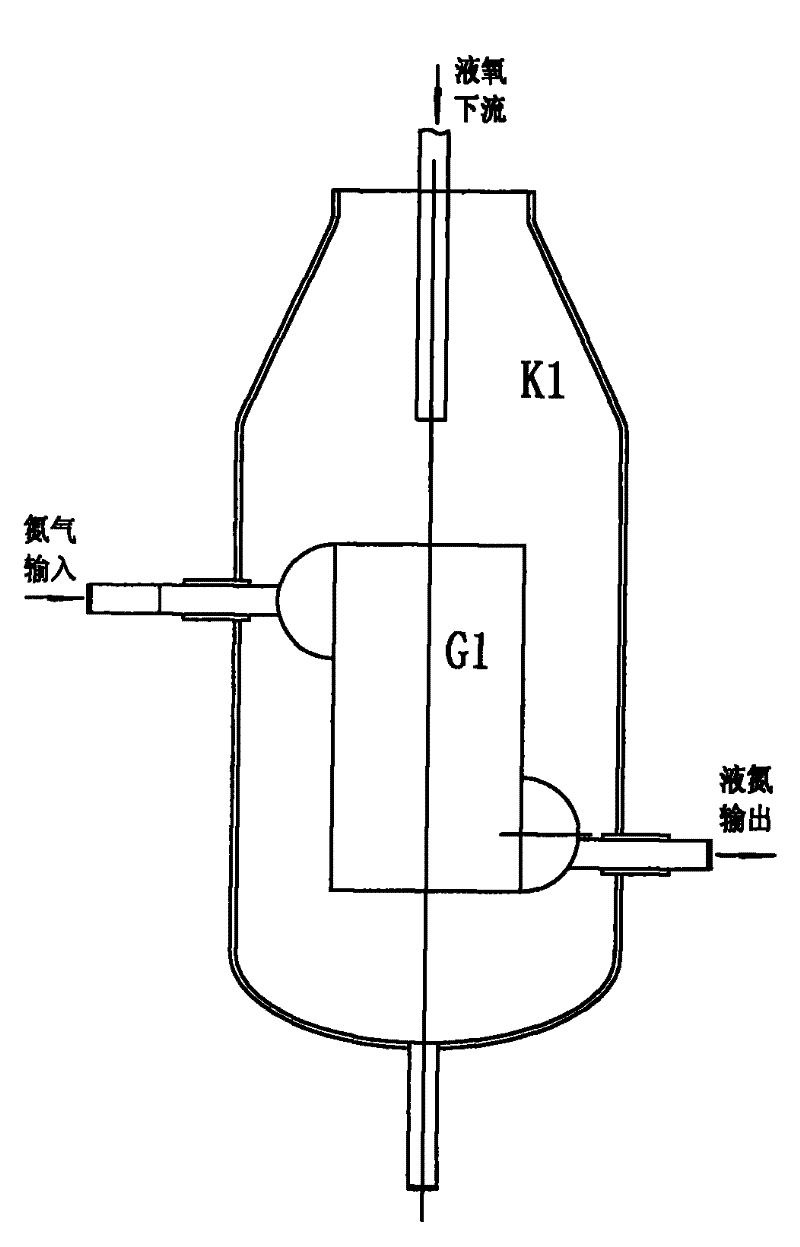

[0036] a. The nitrogen output from the oxygen and nitrogen liquefaction device YD is passed into the absorption chamber G1 of the evaporator K1 of the first rectification tower to absorb cooling capacity, converted into liquid nitrogen, and then sent back to the oxygen and nitrogen liquefaction device;

[0037] b. The liquid nitrogen output from the oxygen-nitrogen liquefaction device is sent to the second rectification tower condenser K2 to release the cooling capacity, which is converted into nitrogen and then sent back to the oxygen-nitrogen liquefaction device;

[0038] c. Send the liquid oxygen output from the oxygen-nitrogen liquefaction unit into the first rectification tower to release the cooling capacity, and the components (hydrocarbons, krypton, xenon, etc., mainly methane) whose evaporation temperature is higher than oxygen are discharged (from The discharge pipe at the bottom of the evaporator K1 of the first rectification tower is discharged to a special storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com