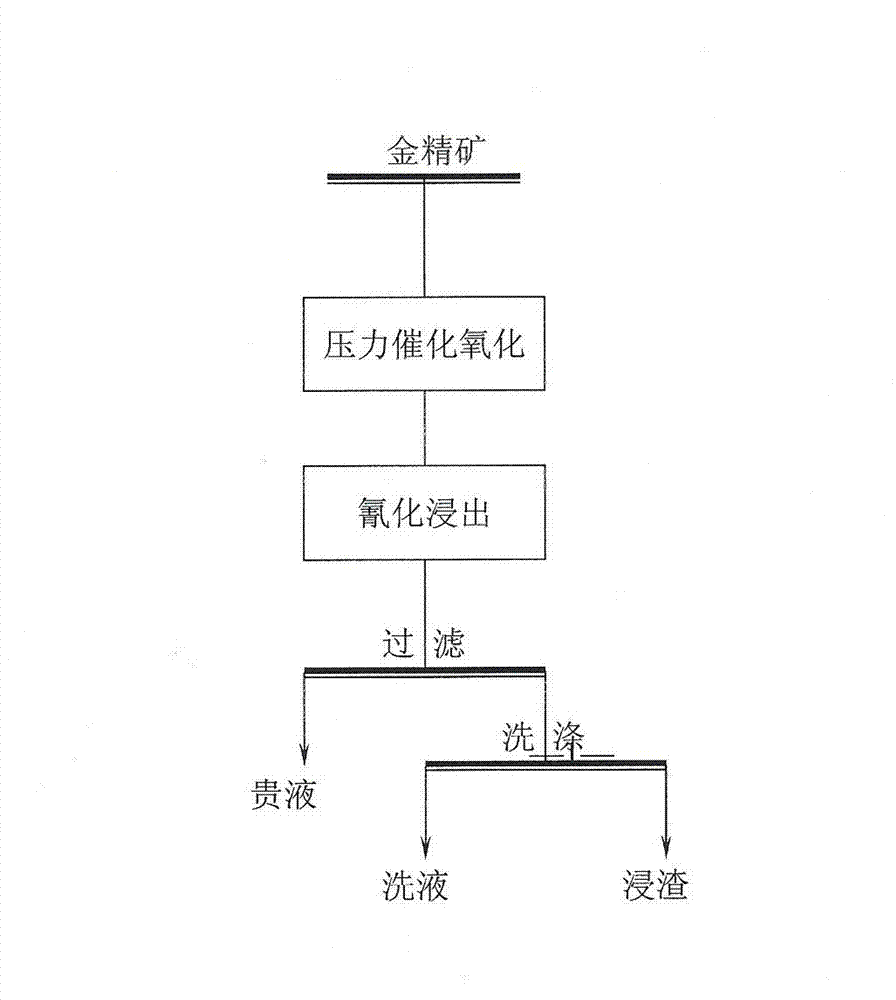

Process for extracting gold from carbonaceous gold concentrate

An extraction process and technology of gold concentrate, which is applied in the field of extraction process of gold in gold concentrate to achieve the effects of reducing environmental pollution, reducing pollution and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

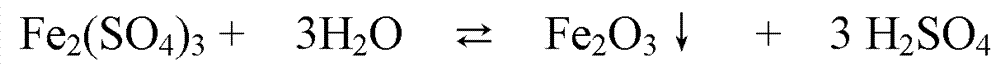

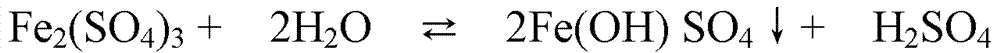

[0044] (1) Acid pressure catalytic oxidation operation:

[0045] Adjust the slurry concentration of carbonaceous gold concentrate to 20%; add H 2 SO 4 and NaNO 3 , adjust the PH value of the pulp to 1-2, and feed it into the pressure oxidation system; under the process conditions that the temperature is 210°C, 2.4MPa partial pressure oxygen is filled in stages, and the oxidation time is 120min, the sulfide minerals are fully oxidized and wrapped The gold is fully exposed dissociated. The oxidation liquid is separated from solid and liquid. After the liquid is processed, the clarified liquid is returned to the oxidation system for precipitation and recovery; after the oxidation residue is thickened, it enters the next step of cyanidation to extract gold;

[0046] (2) Cyanide gold extraction operation:

[0047] The oxidation slag in step (1) is slurried to a concentration of 25% to 35%; the pH value of the pulp is 11 to 12; the alkali treatment time is 1.5 to 2.5 hours; the ...

Embodiment 2

[0053] (1) Acid pressure catalytic oxidation operation:

[0054] Adjust the slurry concentration of carbonaceous gold concentrate to 30%; add H 2 SO 4 and NaNO 3 , adjust the PH value of the pulp to 1-2, and feed it into the pressure oxidation system; under the process conditions that the guaranteed temperature is 180 ° C, 1.0 MPa partial pressure oxygen is filled in stages, and the oxidation time is 90 minutes, the sulfide minerals are fully oxidized and wrapped The gold is fully exposed dissociated. The oxidation liquid is separated from solid and liquid. After the liquid is processed, the clarified liquid is returned to the oxidation system for precipitation and recovery; after the oxidation residue is thickened, it enters the next step of cyanidation to extract gold;

[0055] (2) Cyanide gold extraction operation:

[0056] The oxidation slag in step (1) is slurried to a concentration of 25% to 35%; the pH value of the pulp is 11 to 12; the alkali treatment time is 1.5 ...

Embodiment 3

[0062] (1) Acid pressure catalytic oxidation operation:

[0063] Adjust the slurry concentration of carbonaceous gold concentrate to 40%; add H 2 SO 4 and NaNO 3 , adjust the PH value of the pulp to 1~2, and feed it into the pressure oxidation system; under the process conditions that the temperature is 215°C, 2.8MPa partial pressure oxygen is filled in stages, and the oxidation time is 180min, the sulfide minerals are fully oxidized and wrapped The gold is fully exposed dissociated. The oxidation liquid is separated from solid and liquid. After the liquid is processed, the clarified liquid is returned to the oxidation system for precipitation and recovery; after the oxidation residue is thickened, it enters the next step of cyanidation to extract gold;

[0064] (3) Cyanide gold extraction operation:

[0065] The oxidation slag in step (2) is slurried to a concentration of 25% to 35%; the pH value of the pulp is 11 to 12; the alkali treatment time is 1.5 to 2.5 hours; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com