Heat treatment process of steel forging for hydraulic cylinder of deep-sea oil recovery equipment

A technology for hydraulic cylinders and steel forgings is applied in the field of heat treatment process for the performance of martensitic precipitation hardening stainless steel 15-5PH forgings to achieve the effects of improving microstructure, improving microstructure and stable heat treatment process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

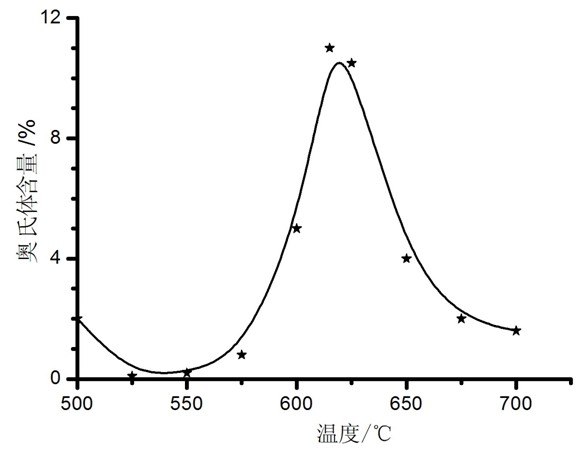

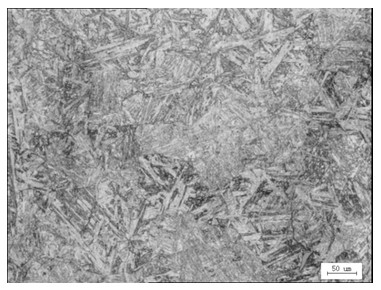

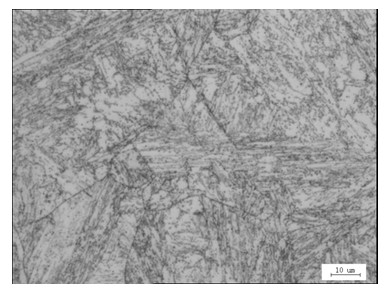

Image

Examples

Embodiment 1

[0034] Embodiment 1 (Process No. B): the solution aging heat treatment process described in the present invention;

Embodiment 2

[0035] Example 2 (Process No. C): The solution aging heat treatment process described in the present invention.

[0036] The specific steps of the comparative example (process number A) are as follows:

[0037] Step A①: Put the 15-5PH hydraulic cylinder forging that has been roughly machined into a well-type resistance heating furnace and heat it to 1040±5°C, and keep it in this temperature range for 180 minutes (the holding time is calculated as 30 minutes per inch of the effective thickness of the forging ), the oil out of the furnace is cooled to below 32°C,

[0038] Step A②: Put the solution-treated hydraulic cylinder forging in step ① into a well-type resistance tempering furnace and heat it to 580±5°C, and keep it in this temperature range for 360 minutes (the holding time is calculated as 60 minutes per inch of the effective thickness of the forging. ), out of the oven and air-cooled to room temperature,

[0039] Step A③: Take a sample from the extended part of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com