Deep nitrogen and phosphorus removal process for surface water body

A deep denitrification and water body technology, applied in aerobic and anaerobic process treatment, water resource protection, adsorption water/sewage treatment, etc., can solve the problems of long time and slow ecological restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

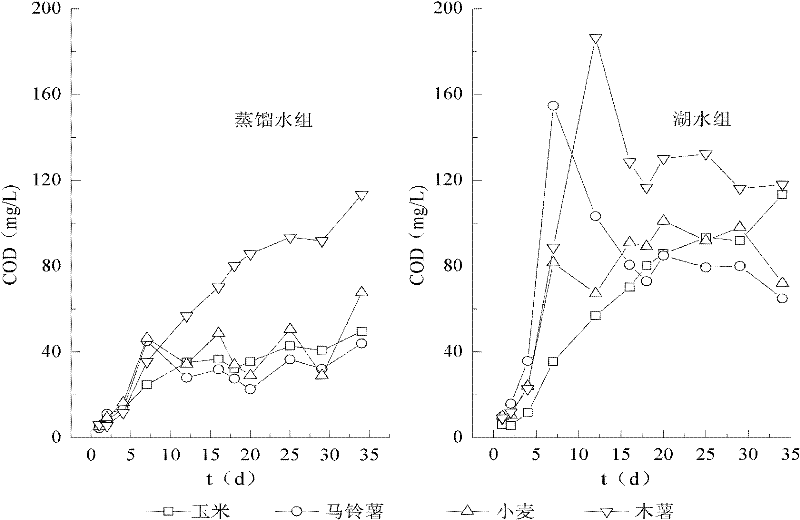

[0032] Embodiment 1: preparation of solid carbon source

[0033] Starch is used as a carbon source, and polyvinyl alcohol is used as a skeleton to construct a slow-release carbon source material. Wheat, corn, potato, and tapioca starches were respectively selected to prepare slow-release organic carbon source material C-80 through solution wet blending and low-temperature jelly molding technology. The specific methods are as follows:

[0034] Weigh 40g of starch, add an appropriate amount of solvent water, and heat until gelatinization and dissolution under stirring. Different starches show different characteristics when gelatinization. Keep it for 1 hour, and mix with 60g of polyvinyl alcohol that has been dissolved in a 95°C water bath. Evenly, cool to room temperature, put in a low-temperature refrigerator, repeat the freezing-thawing process 4 times, and store the obtained product in a 4°C refrigerator for later use.

[0035] Cassava is in a state of continuous release in...

Embodiment 2

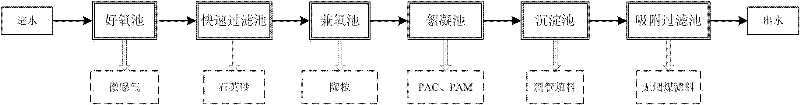

[0037] The device used in the present invention is as follows:

[0038] 1. Water intake lift pump

[0039] The water intake is lifted by a submersible lift pump, and the lift pump is installed on a bracket fixed on the river revetment for easy inspection and maintenance. A grille is set around the lift pump to intercept large-sized debris and prevent subsequent pipeline blockage.

[0040] Major equipment

[0041] According to the processing capacity of the treatment device, two submersible sewage pumps are used (one for use and one for standby).

[0042] Model: WQ80-60-15-8.0, 8.0kW, Q=80m 3 / h, H=15m, frequency conversion control.

[0043] In addition, install a fixed bracket and a set of grilles.

[0044] A check valve and a flow meter are installed on the outlet pipe to display the instantaneous flow.

[0045] 2. Nitrogen and phosphorus removal pool

[0046] The denitrification and phosphorus removal pool is divided into the core structure of the purification syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com