Method for inducing amorphous silicon film with tin to be crystallized into polycrystalline silicon film

A technology of amorphous silicon thin film and polycrystalline silicon thin film, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high crystallization temperature and difficult application, and achieve simple process structure, low cost and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

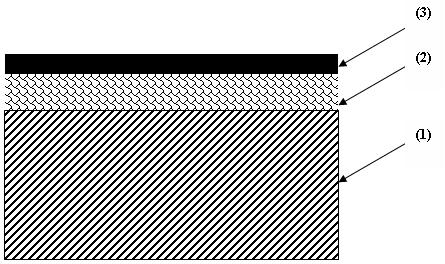

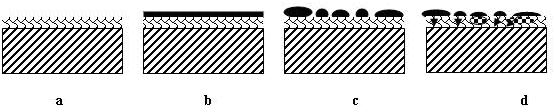

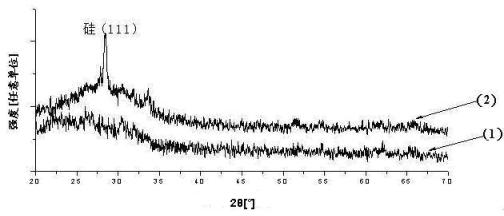

[0031] The process and steps in the embodiment of the present invention are as follows:

[0032] (1) Cut the ordinary glass substrate into 1cm×1cm size, wash off the surface dirt with detergent, and then ultrasonically clean it in acetone and deionized water for 15 minutes, then put it in an oven for drying;

[0033] (2) Deposit a layer of amorphous silicon (a-Si:H) film on a glass substrate by plasma enhanced chemical deposition (PECVD) with a thickness of about 200nm. The substrate temperature during deposition is 200°C and the deposition pressure is 10 -5 Pa, gas glow pressure range 50Pa-250Pa, RF power supply 13.56MHz, gas source is 100% pure silane (SiH 4 ), hydrogen used as dilute silane (H 2 ) purity is 5N;

[0034] (3) Soak the grown amorphous silicon sample in 1% hydrofluoric acid (HF) for 10 seconds, remove the oxide layer on the surface of the amorphous silicon film, take it out, rinse with deionized water, and then nitrogen (N 2 ) to dry, and then put it into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com