Method for preparing micro-nanometer fluid system through compound developing of positive and negative photoresists

A positive and negative photoresist and fluid system technology, applied in the field of micro-nano fluid system preparation, can solve problems such as reduced bonding strength, excessive bonding temperature and pressure, and pipeline blockage, achieving fewer processing steps, ensuring uniformity, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

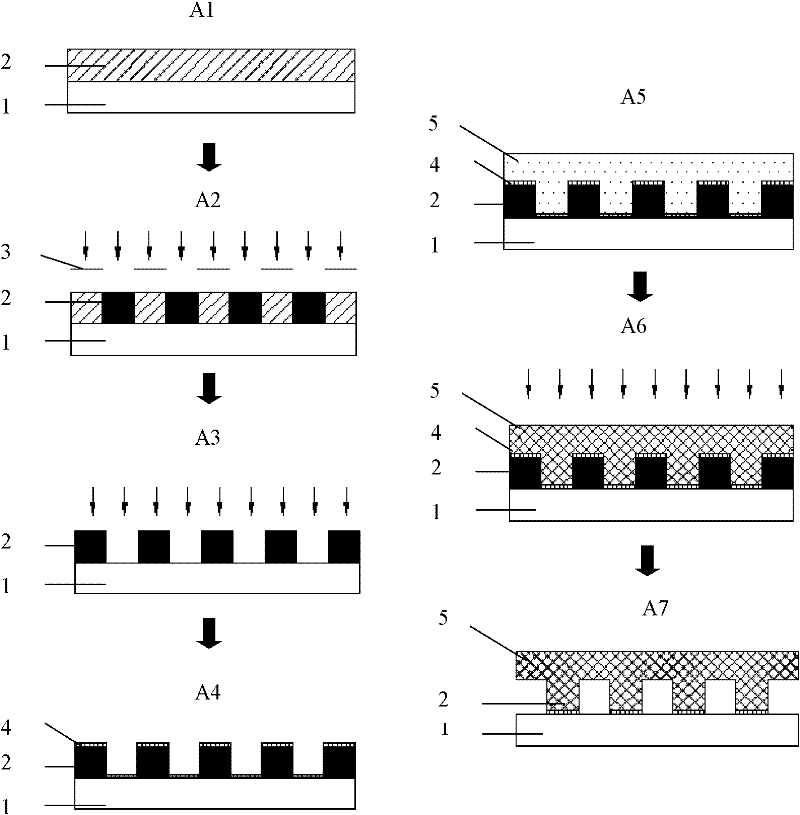

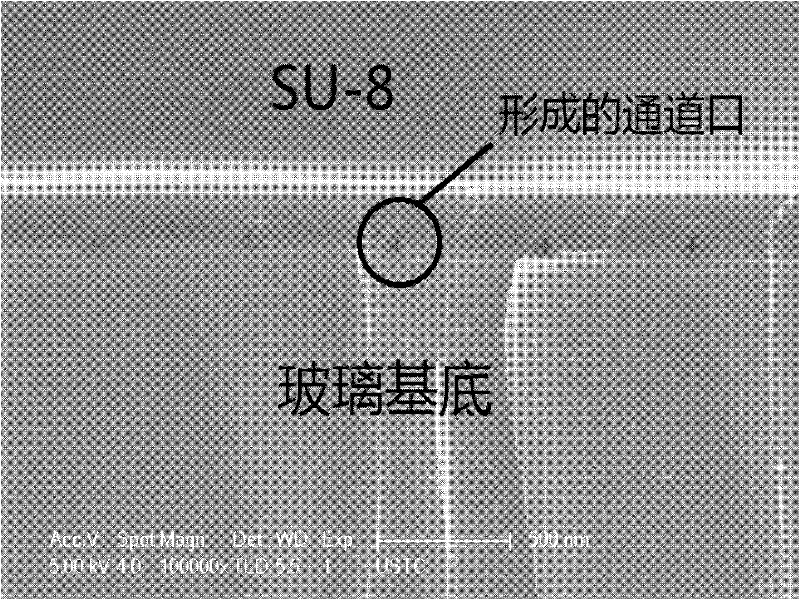

[0026] In the present embodiment, the micro-nanofluidic system is fabricated by the composite development method of positive and negative photoresist, and the operation is as follows:

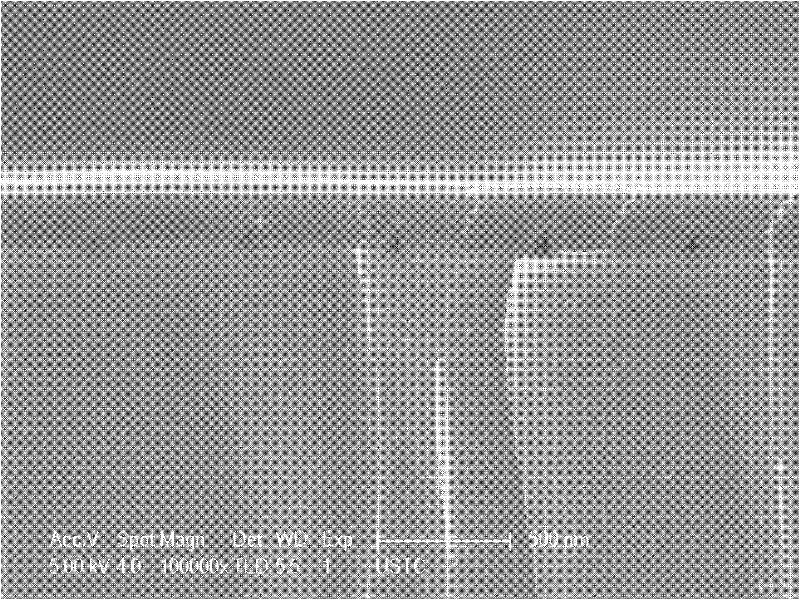

[0027] a. Take the glass sheet as the base, wash it with water and acetone, put it in an oven, and bake it at 130°C for 20 minutes to remove water vapor and residual acetone. After baking, oxygen plasma treatment was performed to increase the surface energy and the adhesion of the photoresist. The vacuum degree of oxygen plasma treatment on the glass substrate was 25Pa, the power was 60W, and the bombardment time was 90 seconds. Spin-coat a layer of AZ1350 positive photoresist with a thickness of about 1.5 microns on its surface, bake at 90 °C for 20 minutes, and then expose it under an exposure machine in the form of mask exposure, with an exposure dose of 200 mJ / cm 2 The exposure time is 2 minutes and 30 seconds, and then it is developed in a 0.5% NaOH solution by mass, and the development ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com