Process for plating trivalent chromium on surfaces of plastic

A technology of trivalent chromium and trivalent chromium salts, which is applied in metal material coating process, liquid chemical plating, superimposed layer plating, etc. and human health hazards, to achieve the effect of excellent quality of finished products, highlighting substantive characteristics, and improving the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

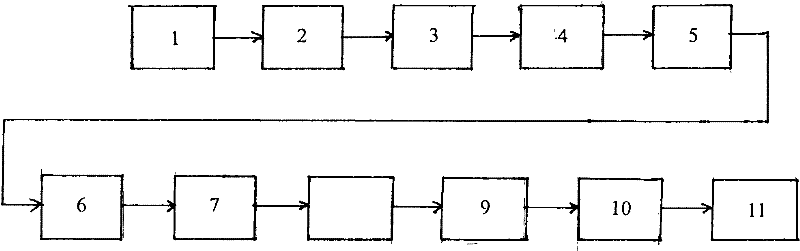

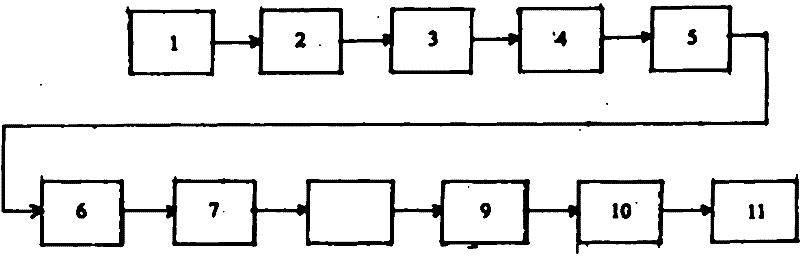

[0020] A process for electroplating trivalent chromium on a plastic surface, characterized in that the surface of a plastic material to be processed is treated in the following process steps:

[0021] (1) to remove surface grease, the composition and concentration (grams per liter) of the mixed solution used are:

[0022] Example

[0023] (2) Surface microscopic roughening treatment, the component concentration (g / L) of the mixed solution used is:

[0024] Example

[0025] (3) surface reduction treatment, the component concentration (gram / liter) of using solution is:

[0026] Example

[0027] (4) Surface colloidal palladium is activated, and the component concentration (gram / liter) of using mixed solution is:

[0028] Example

[0029] (5) surface degumming treatment, the solution component concentration (gram / liter) used is:

[0030] Example

[0031] (6) The surface is plated with chemical nickel, and the concentration of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com