High-performance heat-insulation coating and preparation method thereof

A thermal insulation coating, a high-performance technology, applied in the coating and other directions, can solve the problems of high-cost nano-ATO consumption, insufficient economy, etc., to achieve good thermal insulation effect, prevent gravity sedimentation, and enhance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

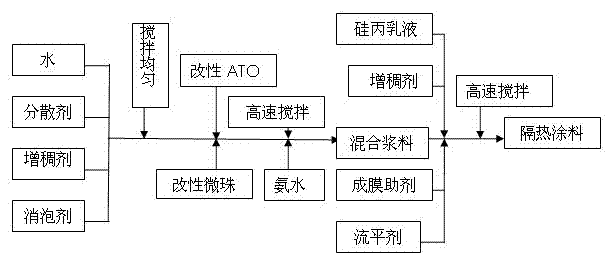

Method used

Image

Examples

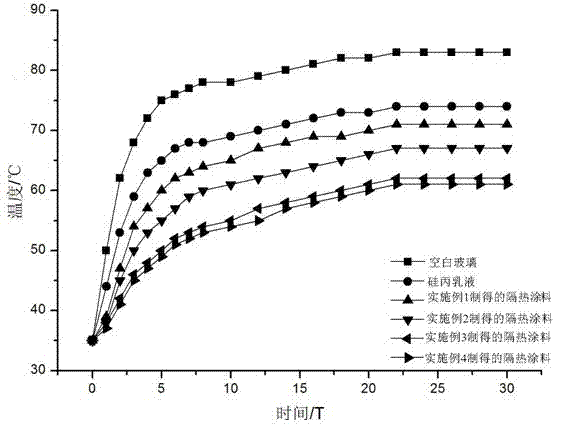

Embodiment 1

[0040] Add 20g of deionized water, 2.2g of BYK-163, 0.8g of DSX-3551, 0.55g of BYK-141 in the mixer and stir evenly, add 15g of KH-570 modified hollow glass microspheres, stir at high speed to disperse 6h, adjust the pH to 8, and prepare a mixed slurry; continue to add 0.3g of DSX-3551, 70g of silicon acrylic emulsion, 1.1g of ethylene glycol butyl ether, and 0.3g of BYK-333 to the mixed slurry at a high speed Stir for 6 hours to prepare a thermal insulation coating containing 0% ATO.

Embodiment 2

[0042] Add 20g of deionized water, 2.2g of BYK-P104S, 0.8g of DSX-3551, 0.40g of BYK-141 and stir well in the mixer, add 2.5g of KH-570 modified ATO powder and 12.5g of KH-570 modified hollow glass microspheres, stirred and dispersed at high speed for 6 hours, adjusted the pH to 8.5, and prepared a mixed slurry; continued to add 0.3g of DSX-3551, 70g of silicon acrylic emulsion, and 0.6g of ethylene glycol to the mixed slurry Butyl ether, 0.3g of BYK-323, etc., stirred at a high speed for 6 hours, and prepared a thermal insulation coating containing 2.27% ATO 2.27%.

Embodiment 3

[0044]Add 24g of deionized water, 2.5g of BYK-P104S, 1g of DSX-3116, 0.55g of BYK-066N and stir well in the mixer, add 3g of KH-570 modified ATO powder and 12g of KH-570 modified hollow Glass beads were stirred and dispersed at high speed for 6 hours, and the pH was adjusted to 9 to prepare a mixed slurry; 0.2g of DSX-3116, 65g of silicon acrylic emulsion, 1.1g of ethylene glycol butyl ether, 0.25g of BYK- 323, stirring at a high speed for 6 hours to prepare a thermal insulation coating containing 2.74% ATO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com