Fireproof and anti-corrosion bifunctional ultra-thin steel structure coating and preparation method thereof

A steel structure coating, dual-function technology, used in anti-corrosion coatings, fire-retardant coatings, chloroprene homopolymer coatings, etc., can solve the problems of no corrosion resistance, poor fire resistance, etc. The effect of reducing toxicity and increasing fire resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

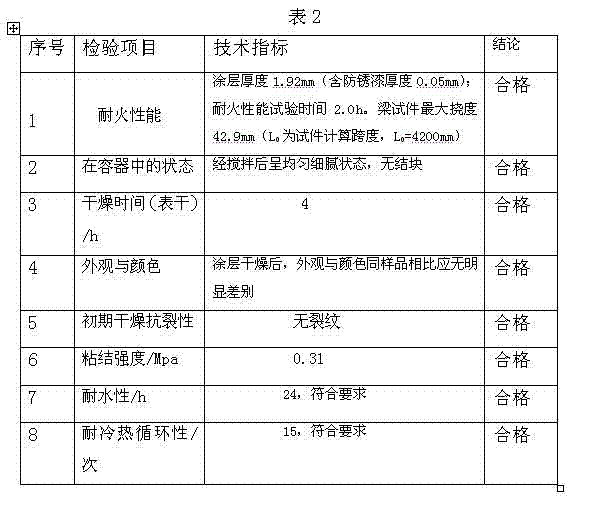

Embodiment 1

[0059] An ultra-thin steel structure coating with dual functions of fire protection and anticorrosion in this embodiment is prepared from the following raw materials in weight percentage: neoprene adhesive 11%; melamine 15%; pentaerythritol 9.7%; pigment and filler 13.8% (of which sericite powder 3.2%, titanium dioxide 5.3%, wollastonite powder 5.3%); No. 1000 solvent gasoline 14%; ammonium polyphosphate 11.4%; chlorinated paraffin solution with 70% chlorine content 14.3%; acrylic resin 2.8% ; amino resin 0.8%; raw vermiculite 1.2%; starch 3.2%; BYK™-380N). The chlorinated paraffin solution with a chlorine content of 70% is prepared by using chlorinated paraffin with a chlorine content of 70% and water at a weight ratio of 1:1. A preparation method of an ultra-thin steel structure coating with dual functions of fire prevention and anticorrosion in this embodiment comprises the following steps: first preparing a chlorinated paraffin solution with a chlorine content of 70%, and...

Embodiment 2

[0062] An ultra-thin steel structure coating with dual functions of fire protection and anticorrosion in this embodiment is prepared from the following raw materials in weight percentage: neoprene adhesive 6%; melamine 20%; pentaerythritol 6%; pigment and filler 16% (6.2% of sericite powder, 3.6% of titanium dioxide, and 6.2% of carbon black); 16.9% of No. 1000 solvent gasoline; 14% of ammonium polyphosphate; 10% of chlorinated paraffin solution with 70% chlorine content; 3.6% of acrylic resin; Amino resin 0.4%; raw vermiculite 1.6%; starch 2.8%; zinc borate 0.7%; additives 2.0% (including 1.0% dispersant and 1.0% leveling agent; dispersant uses BYK?-P104; leveling agent uses BYK ?-307). The chlorinated paraffin solution with a chlorine content of 70% is prepared by using chlorinated paraffin with a chlorine content of 70% and water at a weight ratio of 1:1. A preparation method of an ultra-thin steel structure coating with dual functions of fire prevention and anticorrosion ...

Embodiment 3

[0065] An ultra-thin steel structure coating with dual functions of fire protection and anticorrosion in this embodiment is prepared from the following raw materials in weight percentage: neoprene adhesive 16%; melamine 11%; pentaerythritol 12%; pigment and filler 10.5% (including sericite powder 2.5%, titanium dioxide 4%, wollastonite powder 4%); No. 1000 solvent gasoline 12%; ammonium polyphosphate 10%; chlorinated paraffin solution with 70% chlorine content 18%; acrylic resin 2.0% ; amino resin 1.2%; raw vermiculite 0.8%; starch 3.6%; BYK™-380N). The chlorinated paraffin solution with a chlorine content of 70% is prepared by using chlorinated paraffin with a chlorine content of 70% and water at a weight ratio of 1:1. A preparation method of an ultra-thin steel structure coating with dual functions of fire prevention and anticorrosion in this embodiment comprises the following steps: first preparing a chlorinated paraffin solution with a chlorine content of 70%, and then mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com