Foaming glove and production method thereof

A production method and glove technology, applied in the direction of gloves, clothing, applications, etc., can solve the problems that the crosslinking agent and water-based color paste cannot be guaranteed to be removed, and achieve the effect of good overall wearing effect, good wear resistance, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

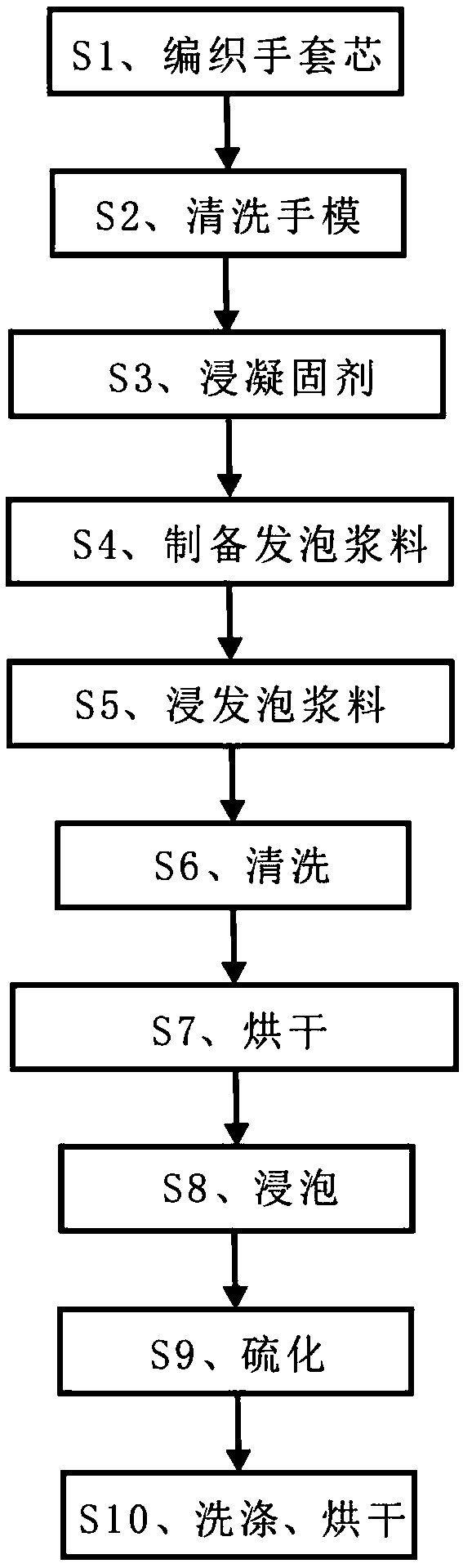

[0048] see figure 1 . Such as figure 1 As shown, the present embodiment discloses a production method of foam gloves, comprising the steps of:

[0049] S1, braided glove core;

[0050] S2. Cleaning the hand mold: select a suitable hand mold according to the specifications of the glove to be produced, clean and dry the hand mold;

[0051] S3, soaking coagulant: Put the glove core on the hand mold and immerse in the coagulant;

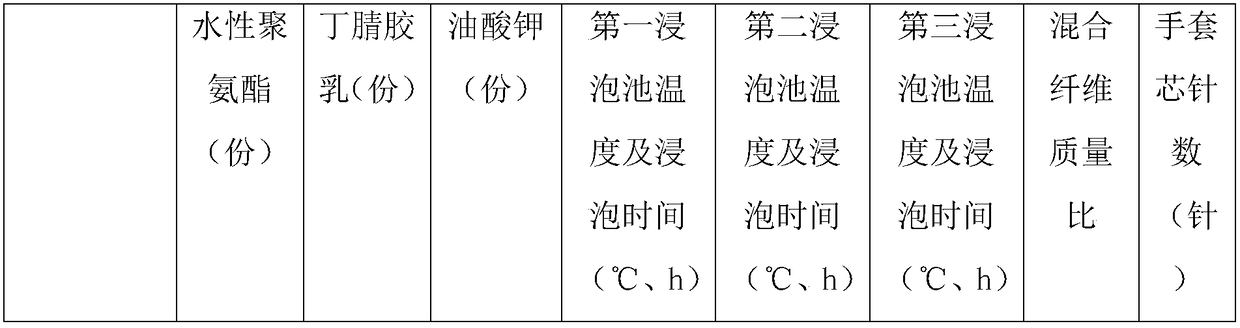

[0052] S4, preparation of foaming slurry: water-based polyurethane, nitrile latex, foaming agent and thickener are fully mixed and stirred to obtain foaming slurry; the foaming agent is potassium oleate, and the thickener is Hydroxymethylcellulose;

[0053] S5. Soaking in foaming slurry: immerse the hand mold in the foaming slurry, the temperature of the foaming slurry is 50°C, and the soaking time is 1min. After soaking the foaming slurry, the hand mold is dried at 115°C for 3 minutes;

[0054] S6. Cleaning: soak the gloves soaked in the foaming s...

Embodiment 2

[0068] The embodiment of the present invention discloses a production method of foam gloves, comprising the following steps:

[0069] S1, braided glove core;

[0070] S2. Cleaning the hand mold: select a suitable hand mold according to the specifications of the glove to be produced, clean and dry the hand mold;

[0071] S3, soaking coagulant: Put the glove core on the hand mold and immerse in the coagulant;

[0072] S4, preparation of foaming slurry: water-based polyurethane, nitrile latex, foaming agent and thickener are fully mixed and stirred to obtain foaming slurry; the foaming agent is potassium oleate, and the thickener is Hydroxymethylcellulose;

[0073] S5. Soaking in foaming slurry: immerse the hand mold in the foaming slurry, the temperature of the foaming slurry is 45°C, and the soaking time is 2 minutes. After soaking the foaming slurry, the hand mold is dried at 120°C for 4 minutes;

[0074] S6. Cleaning: soak the gloves soaked in the foaming slurry in a clean...

Embodiment 3

[0088] The embodiment of the present invention discloses a production method of foam gloves, comprising the following steps:

[0089] S1, braided glove core;

[0090] S2. Cleaning the hand mold: select a suitable hand mold according to the specifications of the glove to be produced, clean and dry the hand mold;

[0091] S3, soaking coagulant: Put the glove core on the hand mold and immerse in the coagulant;

[0092] The coagulant in the step S3 is a calcium chloride solution and a zinc chloride solution, the mass fraction of calcium chloride in the calcium chloride solution ranges from 8wt%, and the mass fraction of zinc chloride in the zinc chloride solution is The range is 8 wt%.

[0093] S4, preparation of foaming slurry: water-based polyurethane, nitrile latex, foaming agent and thickener are fully mixed and stirred to obtain foaming slurry; the foaming agent is potassium oleate, and the thickener is Hydroxymethylcellulose;

[0094] The range of parts by weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com