Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

A high foaming rate, foam glass technology, used in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of small pore size, high density, and inability to keep heat and cold materials in foam glass, so as to improve the foaming rate, pore size, etc. Uniform, high-performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing foamed glass with a high foaming rate by using lead-free high-barium waste lamp tubes. The preparation method is to use lead-free high-barium waste lamp tubes to form raw material glass powder through ball milling, and mix foaming agents such as manganese dioxide, calcium carbonate, and auxiliary The flux sodium fluorosilicate and the stabilizer sodium phosphate are fed into the ball mill for ball milling, and the mixture after ball milling is fed into the high temperature resistant mold for preheating at 400~430°C for 15~20 minutes, and then the temperature is raised to 800~820°C for Foaming, foaming time 20~30min, then cooling to 500~550℃ for annealing, annealing time 35~40min, and finally cooling to room temperature with the furnace.

[0022] Among them, manganese dioxide, calcium carbonate, sodium fluorosilicate and sodium phosphate account for 3%~6%, 4%~8%, 4%~6%, 7%~9% of the total weight of the glass powder respectively; The particle size o...

Embodiment 2

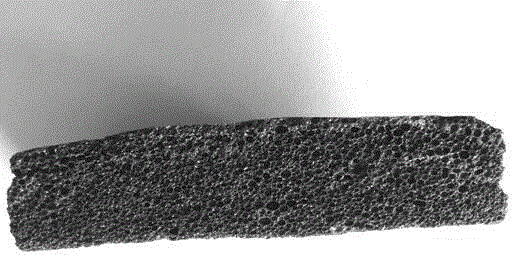

[0029] 100 parts by weight of glass powder, 3 parts by weight of manganese dioxide, 6 parts by weight of calcium carbonate, 5 parts by weight of sodium fluorosilicate, and 9 parts by weight of sodium phosphate are sent into the ball mill for ball milling, and the particle size is 160 mesh; For the mold, the preheating temperature is 420°C for 17 minutes, the foaming temperature is 800°C for 20 minutes, and the annealing temperature is 530°C for 35 minutes. The prepared foam glass as figure 1 As shown, the pore diameter is relatively uniform, the average pore diameter is 2.8mm, the apparent density is 0.71g / cm3, and the compressive strength is 5.24MPa.

Embodiment 3

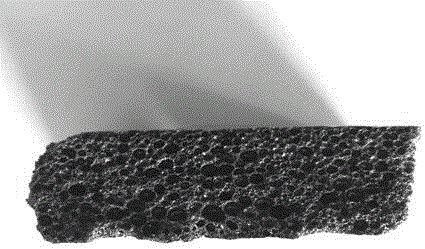

[0031] 100 parts by weight of glass powder, 4 parts by weight of manganese dioxide, 5 parts by weight of calcium carbonate, 4 parts by weight of sodium fluorosilicate, and 7 parts by weight of sodium phosphate are sent into the ball mill for ball milling, and the particle size is 175 mesh; For the mold, the preheating temperature is 420°C for 17 minutes, the foaming temperature is 810°C for 25 minutes, and the annealing temperature is 530°C for 35 minutes. The prepared foam glass as figure 2 As shown, the pore diameter is relatively uniform, the average pore diameter is 3.6mm, the apparent density is 0.64g / cm3, and the compressive strength is 4.53MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com