Method for preparing high-purity protocatechualdehyde from salvia miltiorrhiza

A protocatechuic aldehyde, high-purity technology, applied in the field of medicine, can solve the problems of inability to achieve high purity, no process investigation, low catechuic aldehyde purity, etc., and achieve the effects of low cost of materials, less impurities, and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the preparation of high-purity protocatechualdehyde, its process step is:

[0082] 1. Preparation of Salvia Miltiorrhiza Extract

[0083] 8kg Danshen decoction pieces, decoct with 6 times the amount of alkaline water (0.45% sodium bicarbonate) for 2 hours, filter, decoct the dregs with 5 times the amount of water for 1 hour, filter, combine the extracts, and concentrate to RD1.20 (80°C) , precipitated to 70% with alcohol, and concentrated the supernatant to RD1.35 (60° C.) to obtain 0.46 kg of Danshen extract.

[0084] Wherein, it needs soaking for 30-60 minutes before adding alkali solution and heating for extraction.

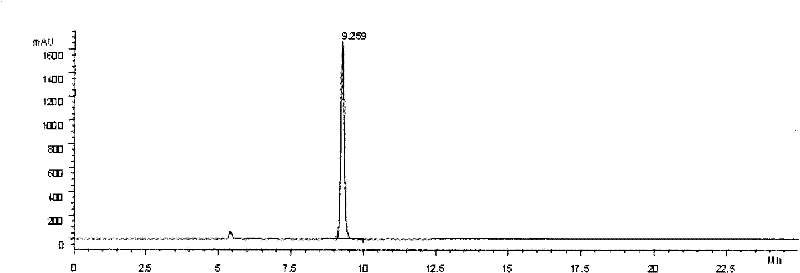

[0085] 2. Chromatography removes relatively small polar Salvia components ( figure 1 )

[0086] Add water to dissolve the salvia miltiorrhiza extract to 0.8 L (0.1 times of the salvia miltiorrhiza decoction pieces), add it into a 3 kg AB-8 macroporous adsorption resin column, elute with water, and collect 18 L of eluate.

[0087] 3. Ch...

Embodiment 2

[0097] Basically the same as Example 1, except that the eluate in step 6 was concentrated under reduced pressure, extracted three times with an equal volume of ethyl acetate, combined, concentrated to dryness under reduced pressure, and obtained.

Embodiment 3

[0099] 1. Preparation of Salvia Miltiorrhiza Extract

[0100] 60kg Danshen decoction pieces, decoct twice (2h, 1h) with 6 times the amount of alkaline water (0.45% sodium bicarbonate) and 5 times the amount of water respectively, filter, combine the extracts, concentrate to RD1.20 (80°C), alcohol sink to 70%, take the supernatant and concentrate to RD1.35 (60°C), to obtain 3.6kg of Danshen extract.

[0101] 3. Chromatography removes relatively small polar components of Salvia miltiorrhiza

[0102] Salvia miltiorrhiza extract was dissolved in water to 6L, added to a 20kg AB-8 macroporous adsorption resin column, eluted with water, and 140L of eluate was collected.

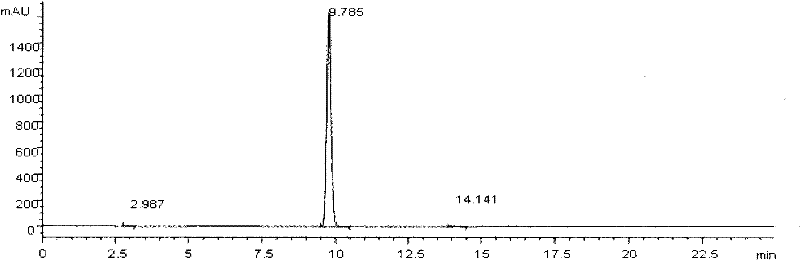

[0103] 3. Separation of protocatechualdehyde by chromatography

[0104] The eluate was adjusted to pH 3.0 with acid, added to AB-8 macroporous adsorption resin filled with 20kg, eluted with acid water with pH 2.5-3.5, collected 180L eluate, discarded, and continued to connect 230L eluent.

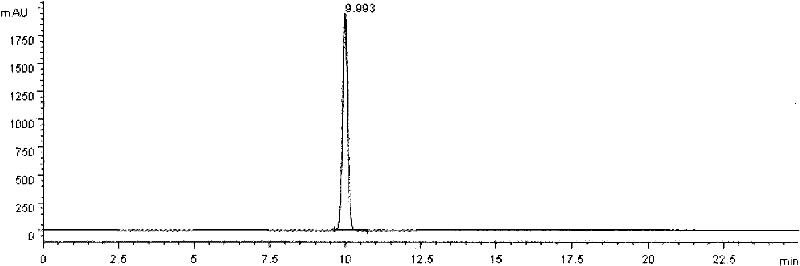

[0105] 4. Deacidifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com