Formation method of semiconductor structure

A semiconductor and pattern layer technology, applied in the field of semiconductor structure formation, can solve the problems of poor pattern quality and affecting the yield of semiconductor structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

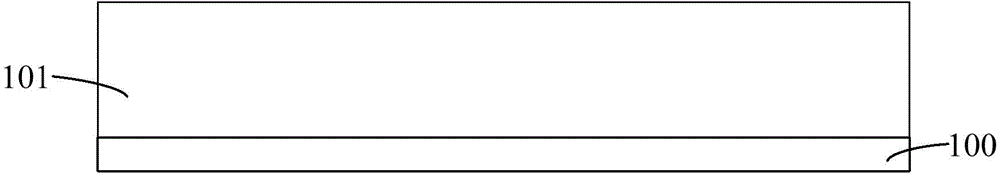

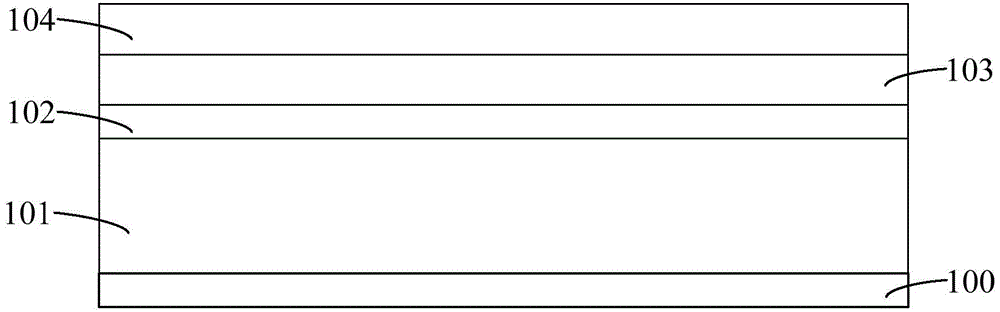

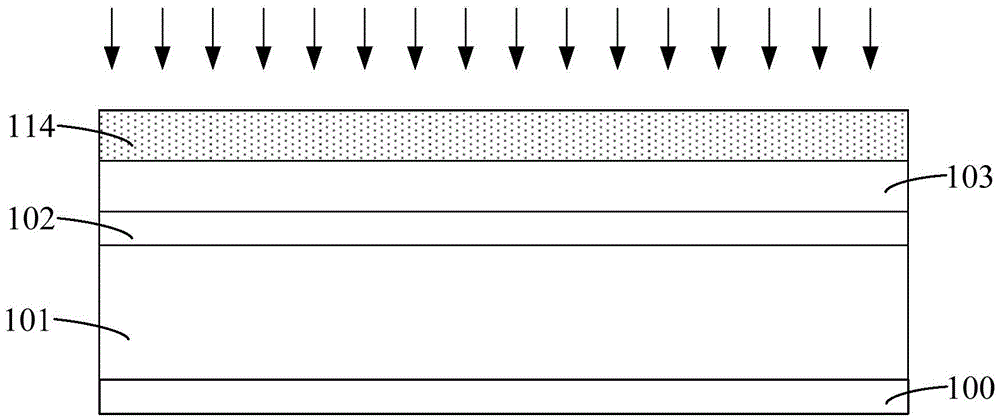

[0036] It can be seen from the background art that the yield rate of semiconductor structures formed in the prior art needs to be improved.

[0037] It has been found through research that oxide materials are usually used as a mask layer in the prior art, and a photoresist layer or a laminated structure of a bottom anti-reflection layer and a photoresist layer is formed on the surface of the mask layer, and there are openings in the photoresist layer; Then, using the photoresist layer with openings as a mask, the mask layer is etched, and the opening pattern of the photoresist layer is transferred into the mask layer.

[0038] When the opening feature size of the photoresist layer is small, if the thickness of the photoresist layer is too thick, the opening morphology of the photoresist layer will be deteriorated, and even easily lead to the collapse of the photoresist layer. Therefore, with the continuous reduction of the size of the semiconductor structure, the characteristi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com