Modular selective catalytic reduction (SCR) denitration rectification grating device

A rectifying grid and modular technology, applied in the field of flue gas denitrification, can solve the problems of increased installation and system operation costs, high requirements for catalyst flow field distribution, difficulty in manufacturing and installing deflectors, etc., to achieve simple and fast production and installation , Inexpensive materials, no need for repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

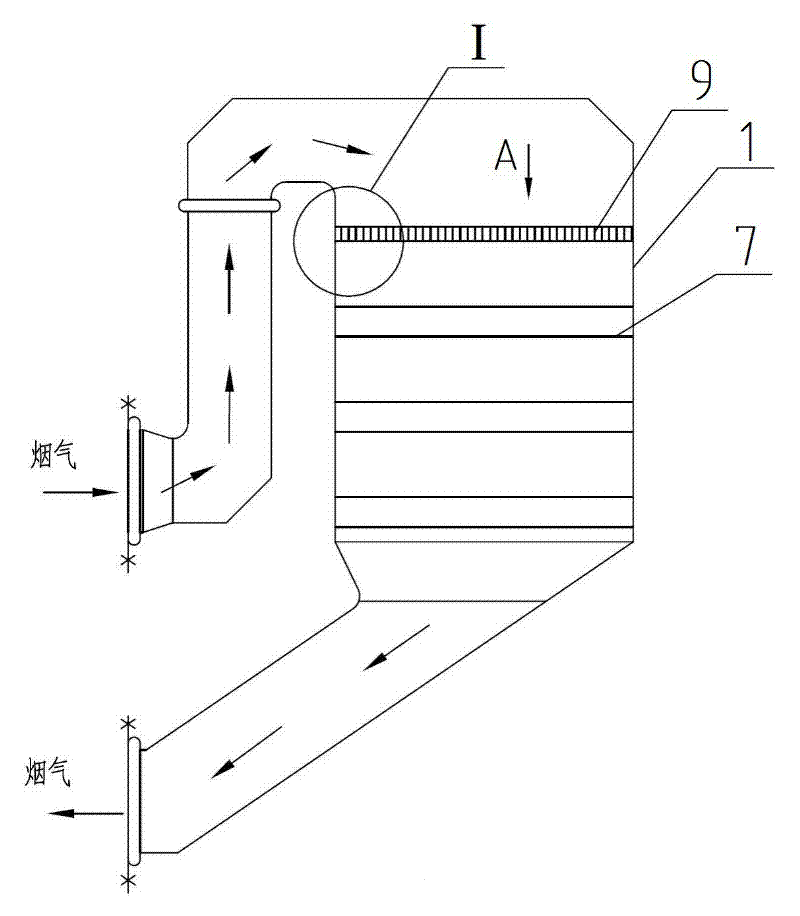

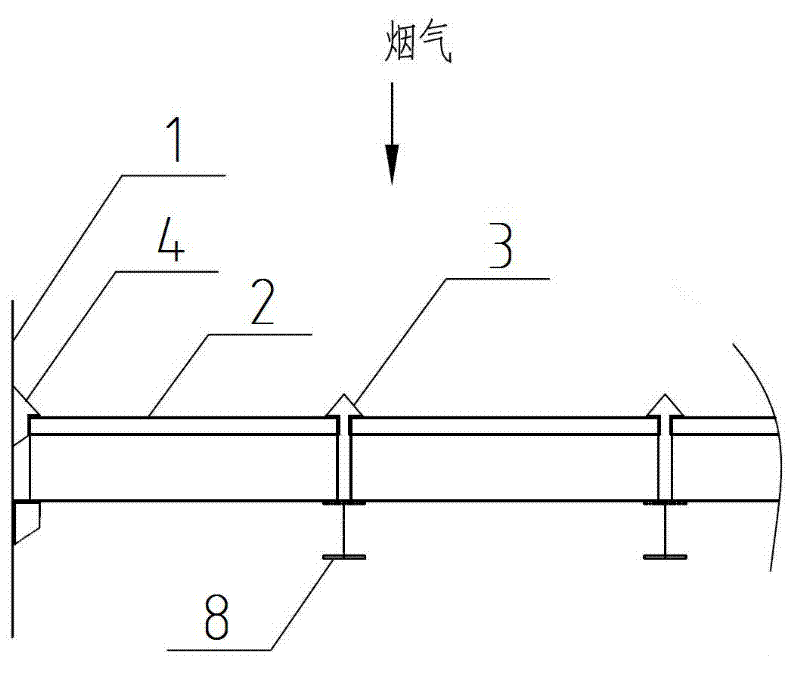

[0017] figure 1 It is a schematic diagram of the installation and use position of the present invention, showing that the modularized SCR denitrification rectifying grid device is placed on the support beam 8 above the first catalytic layer 7 in the SCR reactor 1 ( figure 2 ), located at the front end 9 of the SCR reactor 1, so that after the flue gas passes through the modular SCR denitrification rectifying grille device, the flow direction and flow velocity distribution of the dust-laden flue gas achieve an ideal effect.

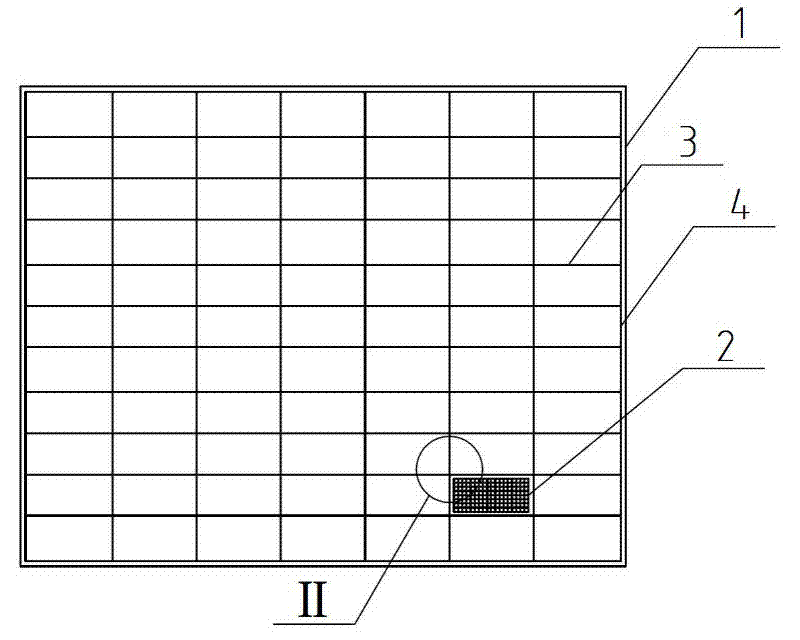

[0018] The schematic diagram of enlarged structure of the present invention is shown in Figure 2 ~ Figure 4 , it can be seen from the figure that the longitudinal grid and the horizontal grid of the rectification module are cross-connected and fixed to each other, forming a grid structure in which a plurality of hollow thin-walled tubes 6 are neatly arranged and connected to each other. The rectification module 2 is surrounded by a ring Surrounding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com