Self-vibration attenuation cable and installation method thereof

An installation method and cable technology, which is applied in the field of bridge cables, can solve the problems of cable vibration, poor effect, adverse effects on structural stability, etc., and achieve the effect of improving service life and simple manufacturing and installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

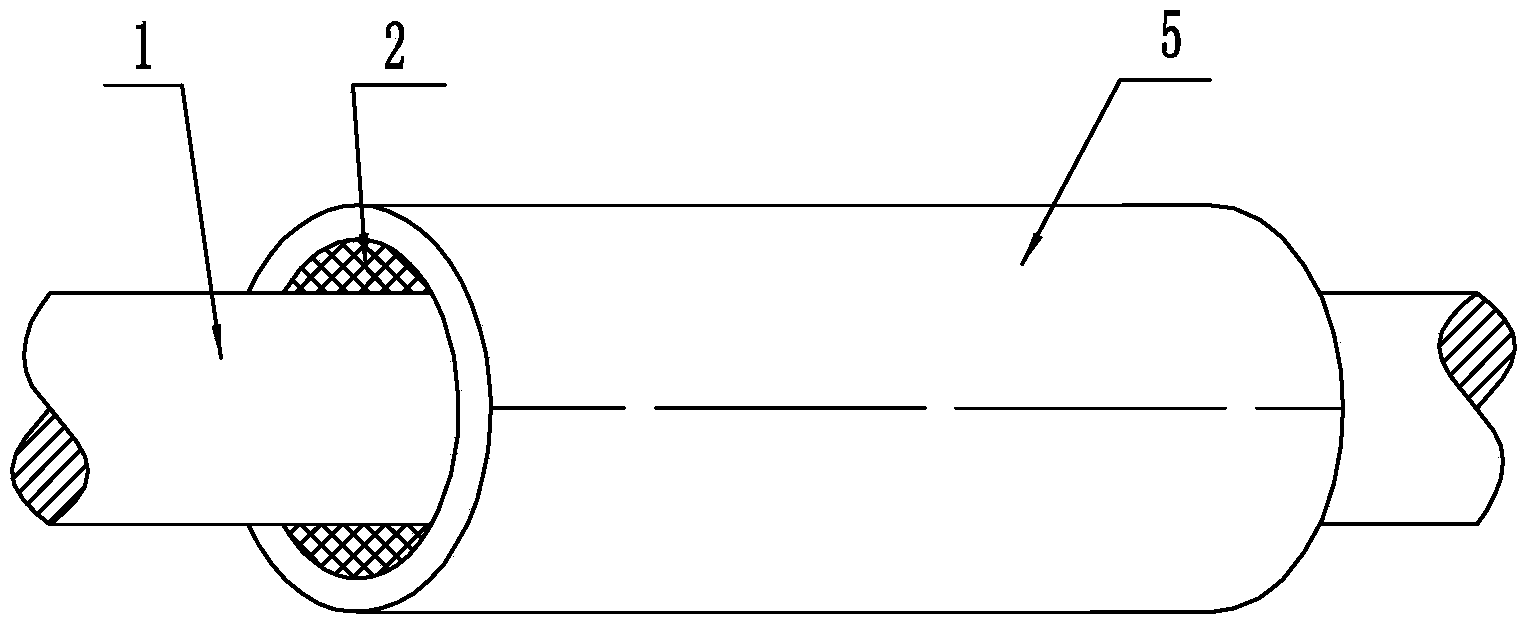

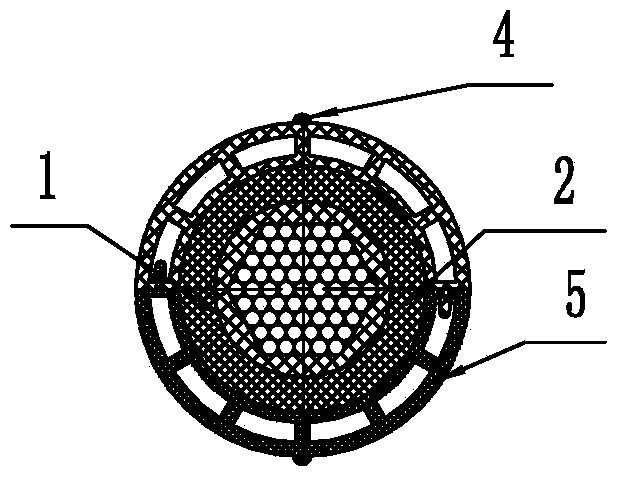

[0041] A self-damping cable, its basic structure is as follows figure 1 As shown, the self-damping cable includes a cable body 1 and a Haval sheath 5 located on the outer layer of the cable body 1. There is an isolation layer 2 between the cable body 1 and the Haval sheath 5 located on the outer layer of the cable body. The isolation layer 2 Including damping rubber 21 or viscoelastic body or slow setting material or a mixture of both damping rubber and viscoelastic body or slow setting material, the isolation layer is either directly distributed on the entire length of the rope, or They are fixedly distributed on the cables through the positioning grooves 51 provided on the inner wall of the Haval sheath.

[0042] Such as Figure 4-6 As shown, the damping rubber block 21 has a semicircular structure, and a boss is arranged on the back thereof, and the damping rubber block 21 is installed in cooperation with the positioning groove through the boss.

[0043] The positioning g...

Embodiment 2

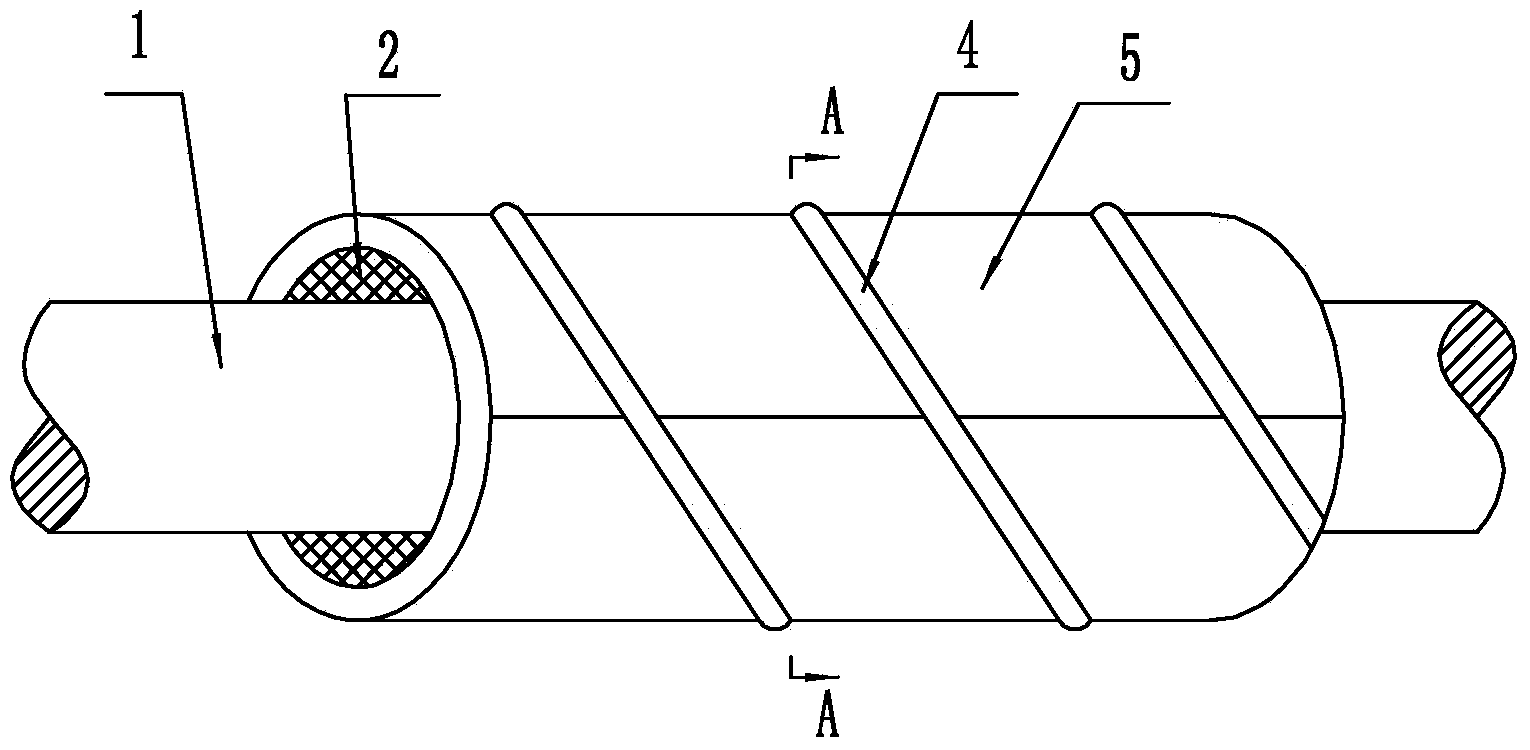

[0047] A kind of self-damping cable with double helical ribs arranged on the outer surface of the Haval sheath, its basic structure is the same as that of Embodiment 1, and the difference from Embodiment 1 lies in: the outer surface of the Haval sheath 5 is provided with double helical ribs. Helical ribs 4, the double helical ribs 4 can be integrally formed with the Haval sheath 5 or wound in the factory, or can be wound after the Haval sheath 5 is fastened on the construction site (see figure 2 , image 3 ).

Embodiment 3

[0049] A self-damping cable with a plurality of pits distributed on the outer surface of the Haval sheath, its basic structure is the same as that of Embodiment 1, the difference lies in: the outer surface of the Haval sheath 5 is geometrically distributed in dots or randomly distributed with multiple dimples3 (see Figure 7 ), the cross-sectional shape of the pits is rectangle, trapezoid, semicircle, semi-ellipse, triangle or other arbitrary polygons, and the distance between the pits is equal or unequal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com