Sheet stainless steel for separators in solid polymer fuel cells, and solid polymer fuel cells using the same

一种固体高分子、燃料电池的技术,应用在不锈钢材料领域,能够解决经济性和资源用量制约等问题,达到发电性能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

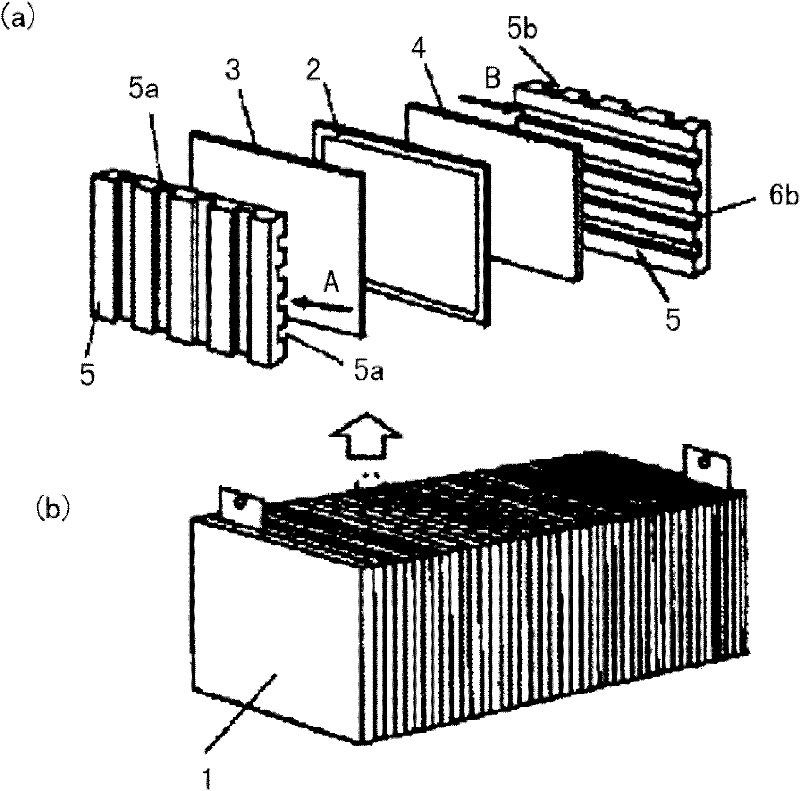

[0242] The procedure for preparing evaluation samples of Test Nos. 1 to 9 for confirming conventional inventions is given below.

[0243] Test No. 1 (SUS obtained in the city)

[0244] A SUS316L stainless steel plate (thickness: 4 mm) shown in Table 2 was used. By cutting and electric discharge machining, it was processed into a predetermined shape of the separator, and the separator for the test was obtained.

[0245] Test No. 2 (gold-plated)

[0246] A SUS316L stainless steel plate (thickness: 4 mm) shown in Table 2 was formed into a separator shape by cutting and electrical discharge machining. Degrease, wash, surface activate, and wash the resulting stainless steel plate in the shape of a separator, and further use a commercially available potassium gold cyanide solution on the electrode contact surface corresponding to the unit cell (the contact portion with the gas diffusion electrode layer) A gold-plated surface was applied to obtain a test separator, and the thickne...

Embodiment 2

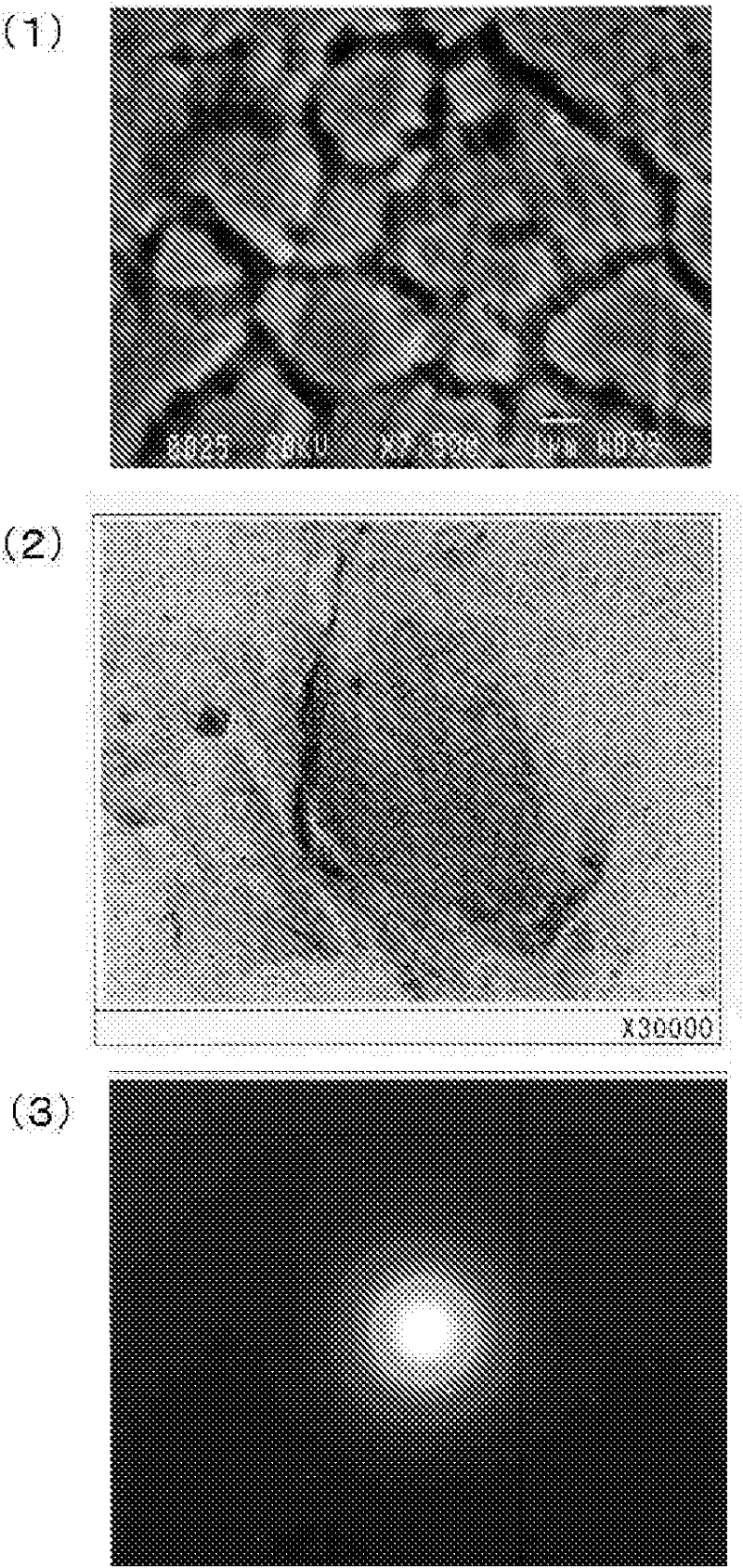

[0279] In order to confirm the preferable interplanar spacing range of the graphitic carbon contained in the graphite layer as the preferable range of the present invention, the following experiment was performed.

[0280] Mesophase globules produced by heat treatment of petroleum pitch and bulk mesophase as a matrix of the globules are heated to prepare a carbonized carbon material. By changing the heating temperature and time for the graphitization heat treatment of the resulting carbon material, graphitic carbons having various interplanar spacings are obtained.

[0281] Table 6 shows the heating temperature and time and the interplanar spacing of the obtained graphitic carbon. Carbons 1-3 are outside the scope of the present invention, and carbons 4-9 are within the scope of the present invention.

[0282] [Table 6]

[0283]

[0284] The same treatment as in Test No. 14 (invention 5) of Example 1 was performed to precipitate conductive dust and obtain a stainless stee...

Embodiment 3

[0290] In order to confirm the ideal range of the surface roughness of the stainless steel plate, the following experiment was performed. Raw materials with various surface roughness can be obtained by adjusting the abrasive grain roughness of the belt grinder and the ferric chloride etching time.

[0291] Changes in contact resistance and fuel cell characteristics when the surface roughness was changed are shown in Table 8.

[0292] [Table 8]

[0293]

[0294] When the average surface roughness Ra was less than 0.10 μm (Example 15 of the present invention), the degree of battery deterioration decreased slightly (the negative value increased). This is presumably because the conductive precipitates and / or the graphite adhering to them under pressure are easily peeled off.

[0295] When the average surface roughness Ra is 1.0 μm or more (Invention 16), there is no problem with battery performance, but partial cracks may occur during press molding.

[0296] On the contrary,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com