High-performance elastic alloy material for aerial hyperbaric cabin and production method thereof

A technology of elastic alloys and production methods, which is applied in the field of new high-performance elastic materials, can solve the problems of restricting the development and application of alloys, and achieve the effects of narrowing the tolerance range, improving mechanical properties, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

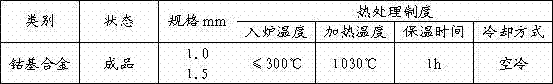

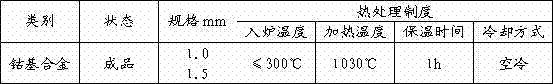

Image

Examples

Embodiment 1

[0030] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 15%, Cr 19%, Co 40%, Si 0.6%, Mn 2%, C 0.08%, P 0.01%, S 0.01%, Mo 7%, Ti 0.5%, Al 0.3%, lanthanum-cerium alloy 0.5%, Fe 15%.

Embodiment 2

[0032] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 14%, Cr 20%, Co 39%, Si 0.3%, Mn 2.2%, C 0.1%, P 0.01%, S 0.01%, Mo 6.5%, Ti 1%, Al 0.2%, Lanthanum-cerium alloy 0.5%, Fe 16.18%.

Embodiment 3

[0034] High-performance elastic alloy material for aviation hyperbaric cabin, its chemical composition is (wt.%): Ni 17%, Cr 21%, Co 40%, Si 0.3%, Mn 1.7%, C 0.07%, P 0.01%, S 0.01%, Mo 6.5%, Ti 0.35%, Al 0.4%, lanthanum-cerium alloy 0.5%, Fe 12.16%.

[0035] The production method of above embodiment 1-3 comprises the following steps:

[0036] 1. Vacuum melting:

[0037] (1) Raw material preparation: the charge is Ni plate, metal Cr, industrial pure Fe and metal Mn, Co and other materials, which are baked and used for later use;

[0038] (2) Charging: Load Ni, Cr, Fe, Co furnace materials that have been baked into the intermediate frequency smelting furnace, and put C, Mn, Si, and lanthanum-cerium alloys into the material cup.

[0039] (3), refining:

[0040] For low-power chemical materials, after the material is 70% melted, increase the power to melt at a high speed. When it is fully melted, it will enter the refining period after reaching the refining temperature. Refin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com