Carbon and ferroferric oxide mesoporous compound material, preparation thereof and application thereof in environmental sewage treatment

A technology of ferric tetroxide and composite materials, which is applied to carbon and ferric tetroxide mesoporous composite materials and their preparation and application in environmental sewage treatment, can solve problems such as complicated preparation process, and achieve high product purity, High productivity and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

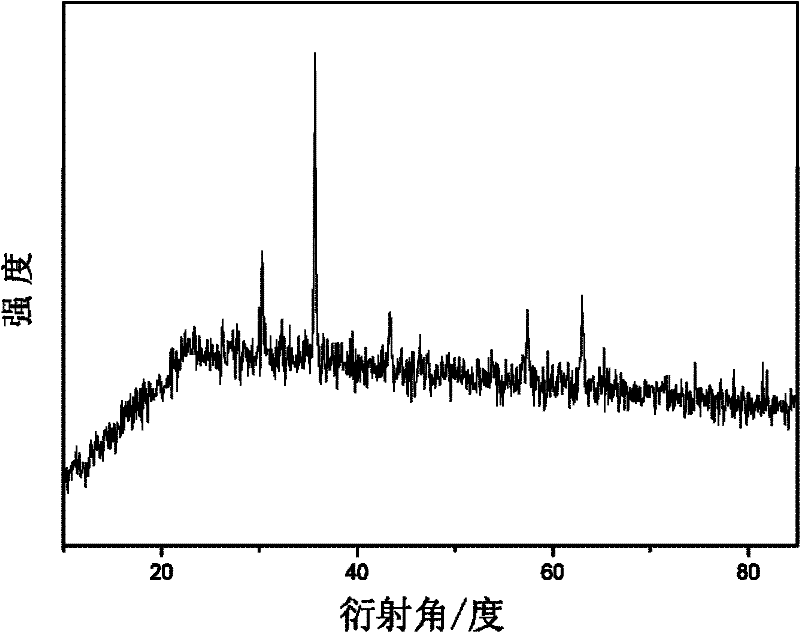

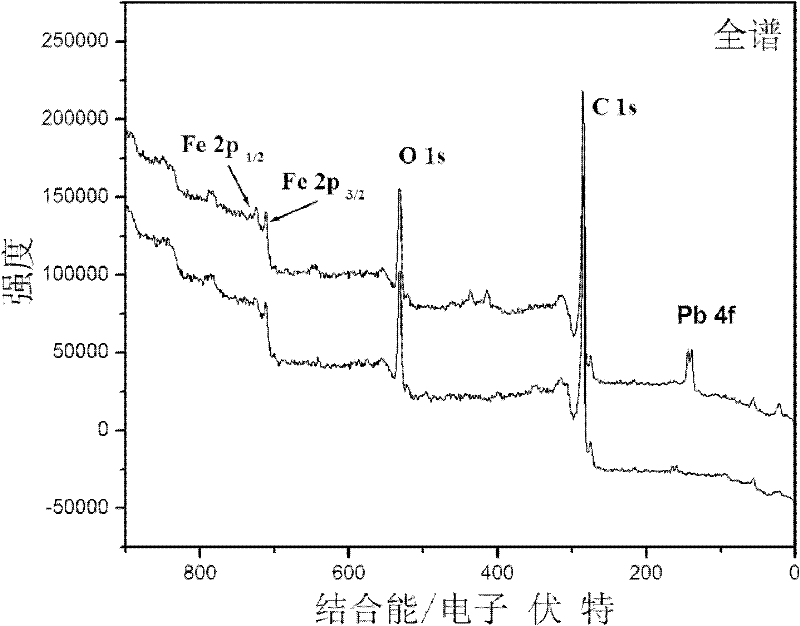

[0030] Preparation of Carbon and Fe3O4 Composite

[0031] The preparation steps are as follows:

[0032] 1), adding 3.0 grams of chitosan to 100 mL of acetic acid aqueous solution with a volume concentration of 3%, forming a homogeneous solution under magnetic stirring, adding 3.6 milliliters of 0.5 mol / L ferric nitrate solution to chitosan under magnetic stirring In the acetic acid solution of sugar, continue magnetic stirring to mix into a homogeneous solution.

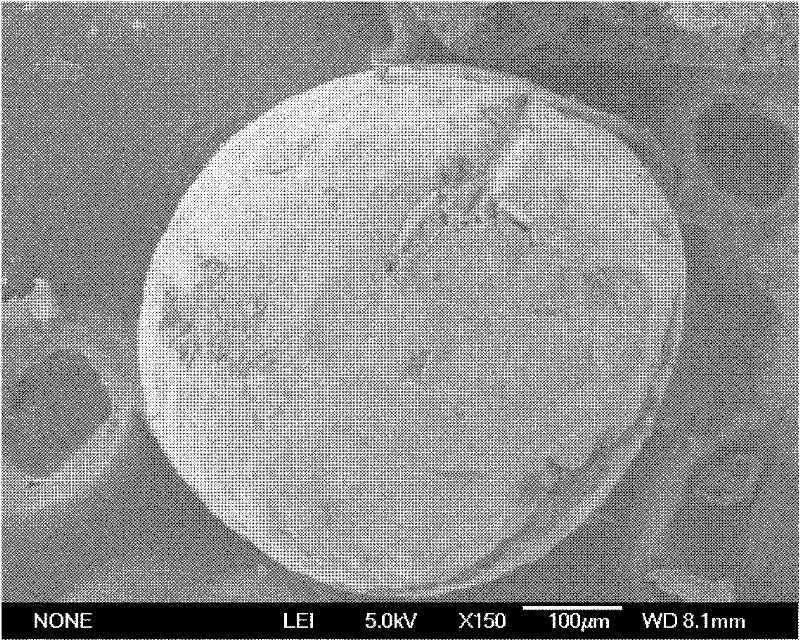

[0033] 2), using a 2 ml syringe, take the above solution and add it dropwise to a petri dish containing a 3mol / L sodium hydroxide solution at a height of about 6 cm. The volume of the sodium hydroxide solution is 2% of the volume of the petri dish / 3 or more, the sodium hydroxide solution is greatly excessive, and a spherical product is formed immediately.

[0034] 3), filter the obtained product, and wash it repeatedly with distilled water several times to remove the residual sodium hydroxide on the surface of th...

Embodiment 2

[0036] Carbon and ferroferric oxide composite material adsorption experiment of lead in sewage prepared in embodiment 1

[0037] 1. Weigh 100 mg of the composite adsorbent obtained;

[0038] 2. Weigh 1.5986 grams of lead nitrate solid and dissolve it in deionized water to prepare a concentration of 1000 mg L -1 Standard solution of lead:

[0039] 3. Pipette the standard solution in step 2 and dilute to 2.0, 4.0, 6.0, 8.0, 10.0 and 20.0mg L respectively -1 100 ml each of the simulated sewage:

[0040] 4. The experiment of adsorbing lead in sewage is carried out at room temperature without adjusting the pH value of sewage. The concentration of carbon and ferroferric oxide composite material is 1.0g L -1 After the adsorbent is evenly dispersed in the sewage, start timing. The whole adsorption process is kept mechanically stirred, and samples are taken at different times. The sampled liquid is filtered with a filter membrane with a diameter of 0.45 μm. After filtering out the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com