Maximum torque control method for salient-pole permanent-magnet synchronous motor

A technology of permanent magnet synchronous motor and maximum torque, which is applied in the field of current generation of d-axis current command id*, salient pole permanent magnet synchronous motor vector control, q-axis current command iq*, and can solve the problem of maximum deviation of current operating point Torque control, complex generation process, no comprehensive consideration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

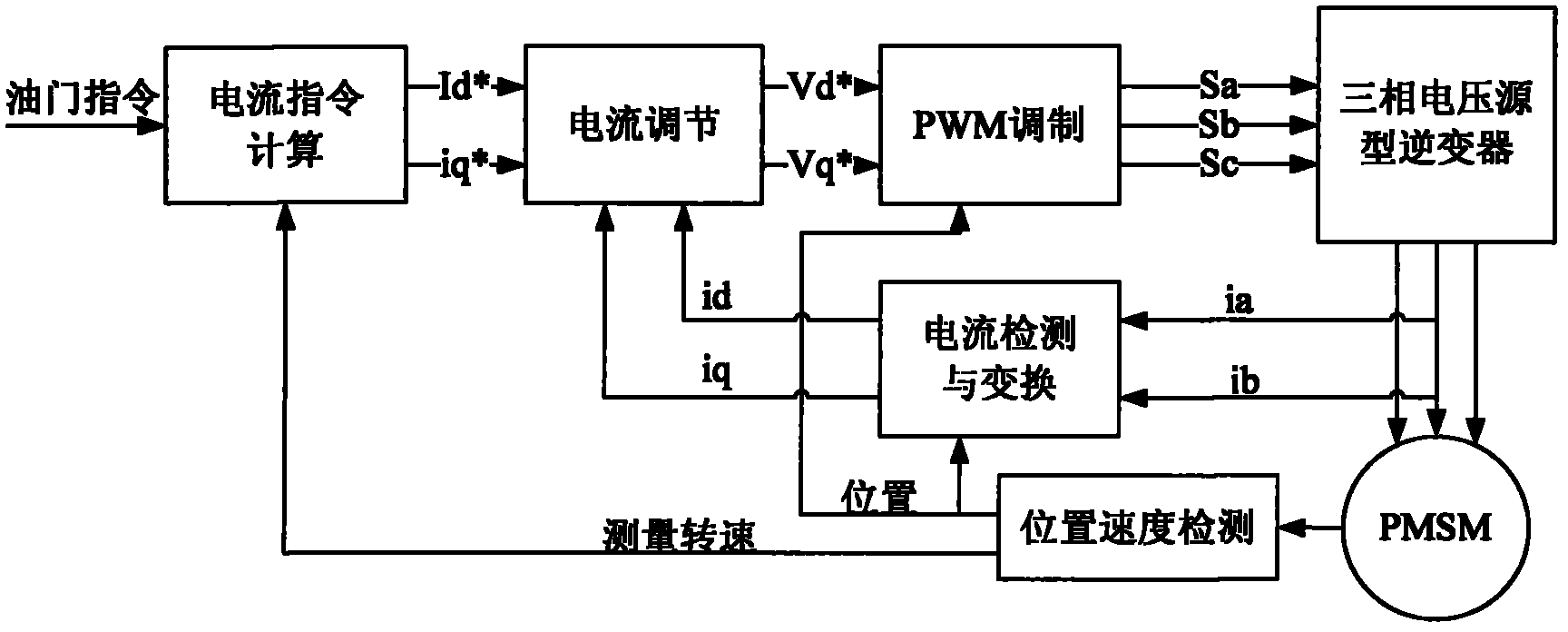

[0041] The vector control system structure of the embodiment of the present invention is as follows figure 1As shown, it includes a permanent magnet synchronous motor (PMSM), a three-phase voltage source inverter, a PWM modulation unit, a current detection and conversion unit, a current regulation unit, a current calculation unit and a position speed detection unit.

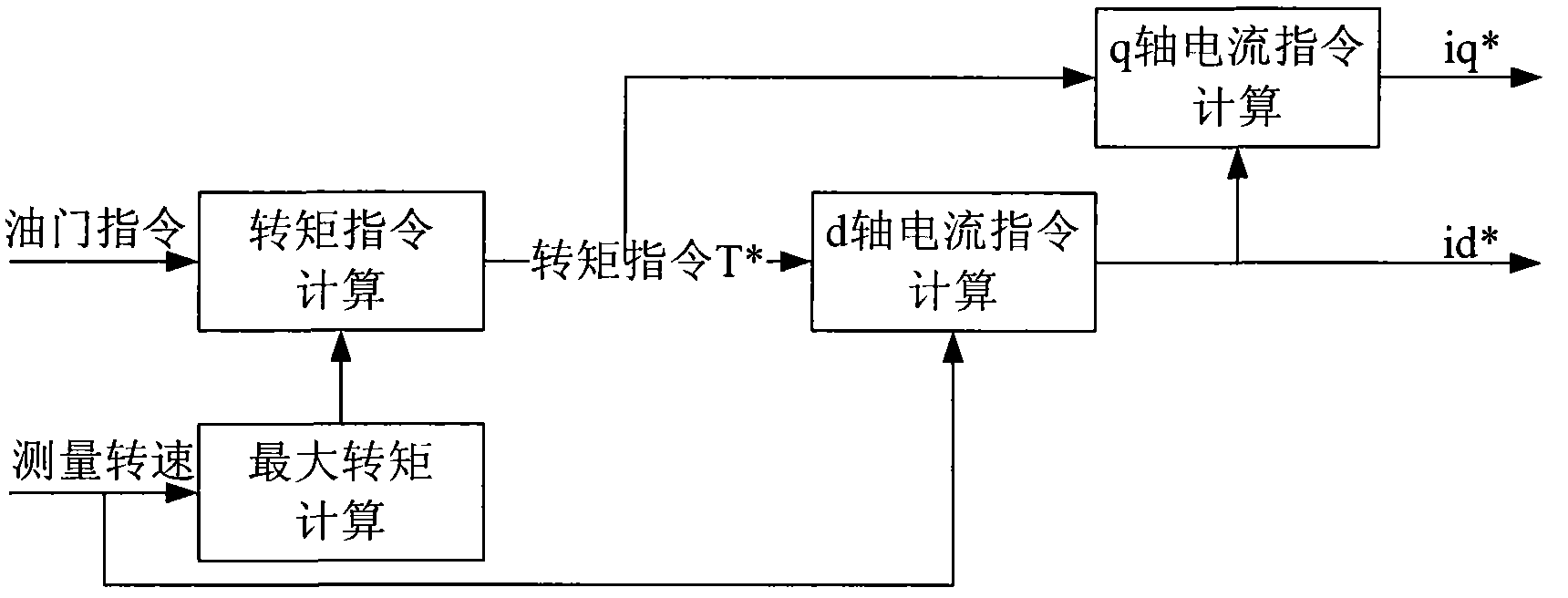

[0042] figure 2 shown as figure 1 A detailed block diagram of the medium current command calculation unit, including a torque command calculation unit, a maximum torque calculation unit, a d-axis current command calculation unit, and a q-axis current command calculation unit.

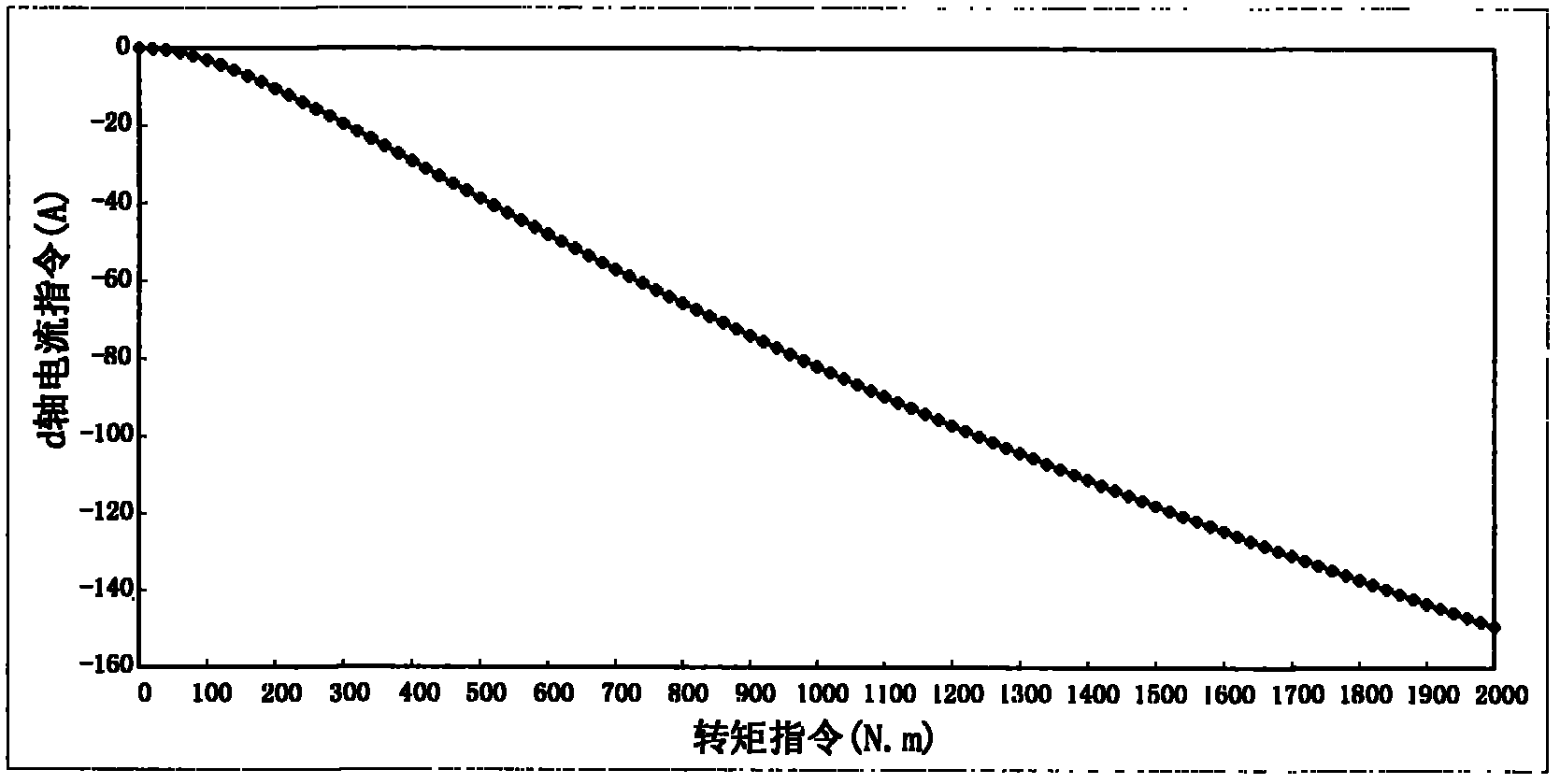

[0043] In order to verify the method of the present invention, a 130kW permanent magnet synchronous motor is used for simulation verification. The motor parameters are: bus voltage 540V, number of pole pairs p=2, winding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com