Composition for battery diaphragm, battery diaphragm and lithium-ion secondary battery

A battery separator and secondary battery technology, applied in the field of lithium ion secondary batteries, can solve the problems of poor battery cycle performance and low safety of battery separators, and achieve the advantages of reducing internal resistance of the separator, easy industrial implementation conditions, and ensuring cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

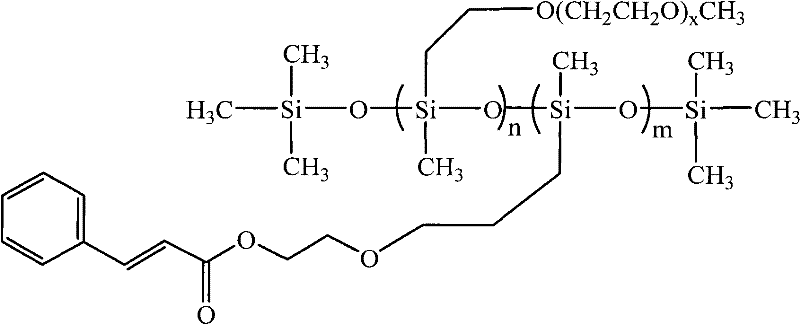

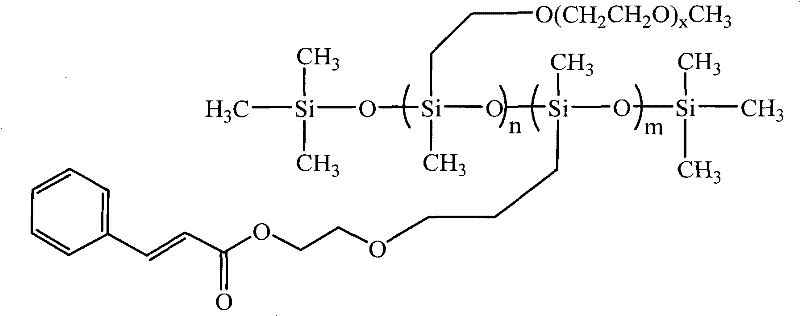

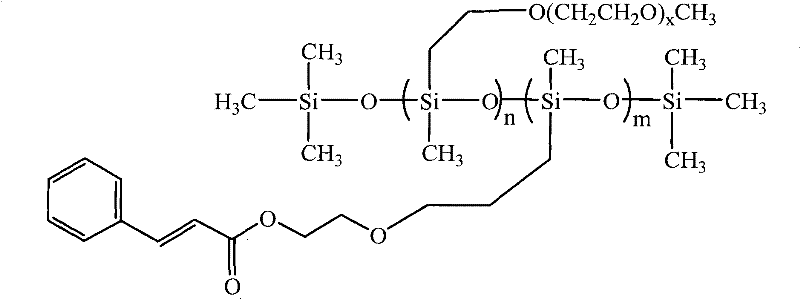

[0024] The preparation method of the composition for a battery separator of the present invention comprises mixing the modified polysiloxane shown in Formula 1 and an inorganic filler in a solvent, stirring uniformly and ball milling to a desired particle size.

[0025] The present invention also provides a battery separator, which is obtained by coating the composition for separator on both sides of a porous polyolefin film and curing it, characterized in that the composition for separator is the composition for battery separator provided by the present invention .

[0026] The porous polyolefin film is a variety of polyolefins that are commonly used as battery separators, such as polypropylene (PP), polyethylene terephthalate (PET) or polyethylene (PE), which are common to those skilled in the art. The pore diameter of the porous polyolefin membrane is 50-300nm, the porosity is 15-50%, and the thickness is 10-40μm.

[0027] In the present invention, the battery separator ca...

Embodiment 1

[0042] (1) Preparation of modified polysiloxane: The modified polysiloxane shown in Formula 1 of this example was prepared by using the method disclosed in the example of US2005271948A1, wherein n is 60, m is 50, and x is 3.

[0043] (2) Dissolve the modified polysiloxane prepared in step (1) into THF to form a 2.5wt% solution; add BaTiO 3 , BaTiO 3 The weight ratio to the modified polysiloxane is 10:1; after mixing evenly, transfer to a ball mill for ball milling until BaTiO 3 The average particle diameter was 400 nm, and a separator slurry was obtained.

[0044] (3) Adopting the dipping coating method, coat the separator slurry obtained in step (2) on both sides of the PE film (thickness 18 μm, porosity 45%), and the coating thickness is 3 μm; placed under a 100W high-pressure mercury lamp, with Ultraviolet light with a wavelength of 365nm is irradiated, the irradiation distance is 10cm, and the irradiation time is 10min.

[0045] Through the above steps, the battery sepa...

Embodiment 2-5

[0047] The same steps as in Example 1 were used to prepare the battery separators of Examples 2-5, except that the components and contents of the separator composition are shown in Table 1 below:

[0048] Table 1

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com