Method for synthesizing mesocarbon microbead micro-nano composite material by microwave radiation method and application of composite material

A technology of mesophase carbon microspheres and microwave radiation method, which is applied in the field of preparation of micro-nano composite materials, can solve the problems of low positive current density, large polarization, and less microstructure, and achieve no temperature hysteresis effect, regular structure, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: MnO 2 Preparation of Nanosphere / MCMB Composite

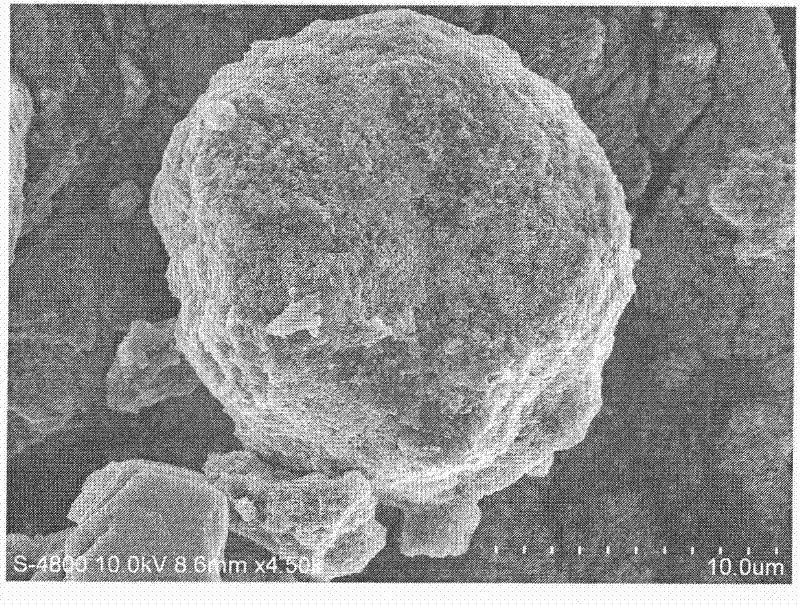

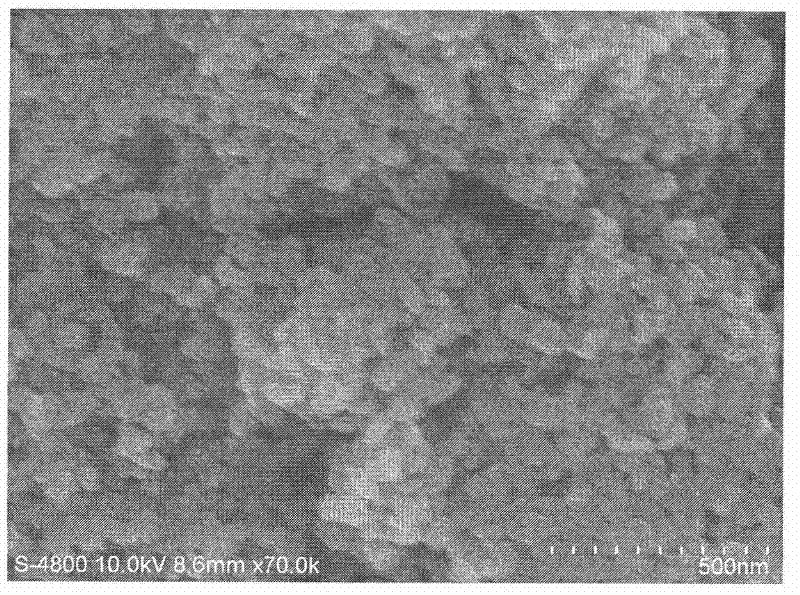

[0046] At room temperature, 1.5 grams of MCMB was dispersed in a 10% ethanol aqueous solution by mass ratio, and 0.2 grams of potassium permanganate solid was added to this solution, and mixed for 15 minutes under a magnetic stirrer to make the potassium permanganate solution fully adsorbed to the surface of MCMB spheres; then add 1.25mL of 50% Mn(NO 3 ) 2 The concentrated solution was vigorously stirred for 10 minutes, and reacted in a microwave irradiation reactor for 30 minutes. After the reaction, the obtained product was subjected to centrifugation, distilled water washing and absolute ethanol washing several times. The product is MnO 2 Nanosheet / MCMB micro-nano composite. Scanning electron microscopy (SEM) tests showed that ( figure 1 , figure 2 ): The main morphology of the product is that the surface of carbon spheres is ultrafine nanoparticles with uniform dispersion and uniform diameter; Figu...

Embodiment 2

[0047] Example 2: MnO 2 Preparation of Ultralong Nanowire / MCMB Micro / Nano Composite

[0048] At room temperature, disperse 1.5 grams of MCMB powder in 10% ethanol aqueous solution, add 0.4 grams of potassium permanganate solid, and mix for 15 minutes under magnetic stirring, so that the potassium permanganate solution is fully adsorbed to the MCMB sphere surface; add 2.5 mL of 50% Mn(NO 3 ) 2 The concentrated solution was vigorously stirred for 10 minutes, and reacted in a microwave irradiation reactor for 30 minutes. After the reaction, the obtained product was subjected to centrifugation, distilled water washing and absolute ethanol washing several times. The product is MnO 2 Ultra-long nanowire / MCMB micro-nano composite. The SEM test showed that ( image 3 , Figure 4 ): The main shape of the product is mesophase carbon microspheres with a diameter of 20 μm, and the array MnO is uniformly grown on the surface 2 nanoneedle; by Image 6 The high-magnification scanning...

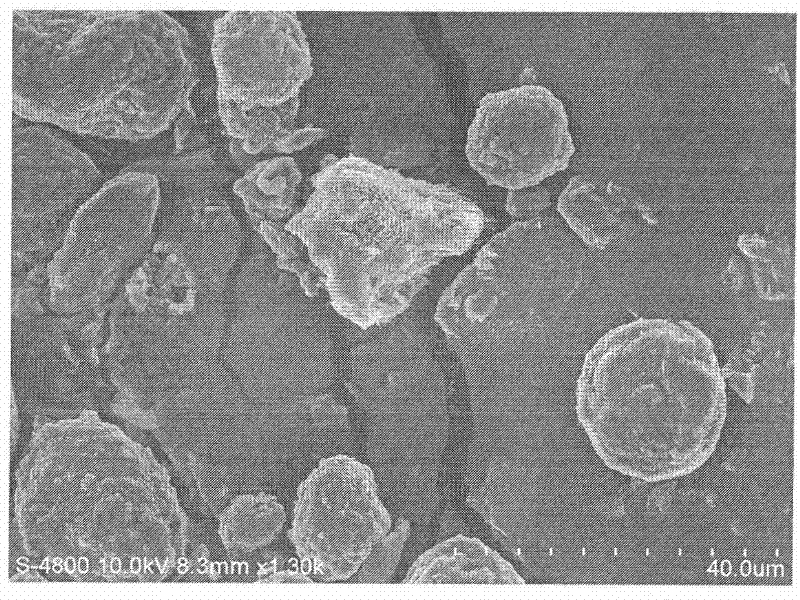

Embodiment 3

[0049] Embodiment 3: Preparation of zinc vanadate nanoparticles / MCMB composite micro-nano material

[0050] At room temperature, accurately weigh the zinc nitrate solid, use distilled water as the solvent, and configure a solution with a molar concentration of 0.00125 mol / L; weigh a certain mass of ammonium metavanadate solid to make the ratio of the number of moles to the number of moles of zinc nitrate 1:2, add hot distilled water at 60-75°C to ammonium metavanadate, stir until completely dissolved to obtain a homogeneous solution, add 10wt% absolute ethanol, then add 1.5 grams of MCMB powder to the above solution, and stir for 15 Minutes until the suspension is evenly dispersed, then transfer the zinc nitrate solution to the mixed suspension of ammonium metavanadate and MCMB powder, and stir vigorously for 10 minutes; transfer the mixture to a round bottom flask and place it in a microwave irradiation reactor React in medium for 30 minutes, and the product after the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com