Polycrystalline silicon thin film and method for preparing polycrystalline silicon thin film by amorphous silicon low-temperature induction

A polysilicon thin film, low temperature induced technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of slow crystallization rate of metal induction method, achieve increased crystallization rate, low nucleation barrier, contact The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

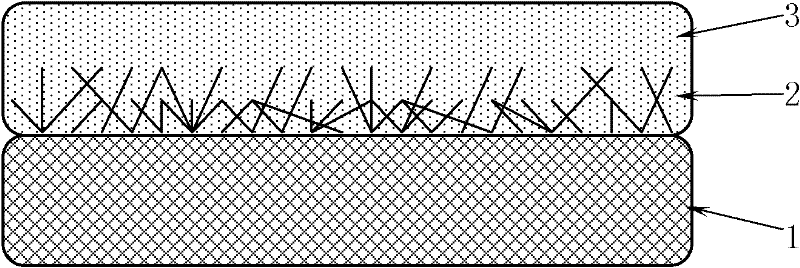

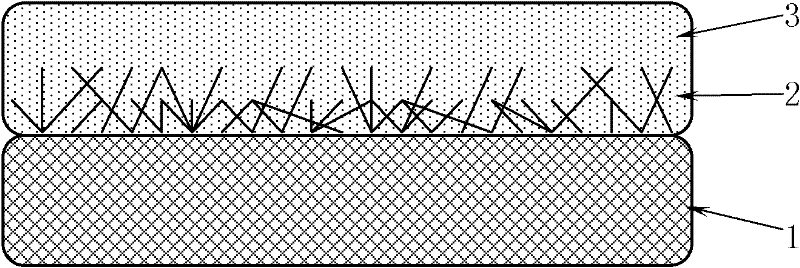

[0015] 1) Tin oxide transparent conductive glass (F-SNO 2 ) is the substrate 1, and a titanium silicide thin film layer and a titanium silicide nanowire composite structure are deposited on the substrate 1 by chemical vapor deposition. The titanium silicide nanowires include nanowires, nanonails, nanorods, and nanowire clusters, in the form of TiSi crystal Mutually;

[0016] 2) Depositing a 1 μm amorphous silicon film layer on the titanium silicide film and titanium silicide nanowire composite structure prepared in step 1) by plasma chemical vapor deposition at 13.56 MHz;

[0017] 3) Annealing and heat-treating the amorphous silicon thin film layer prepared in step 2) at 400° C. for 1 h, so that the titanium silicide nanowire induces the crystallization of the amorphous silicon thin film layer into a polycrystalline silicon thin film layer with large crystal grains, and finally obtains figure 1 Large grain polysilicon thin film shown.

Embodiment 2

[0019] 1) Using zinc oxide transparent conductive glass (Ag-ZnO) as the substrate, a layer of titanium silicide film and titanium silicide nanowire composite structure is deposited on the substrate 1 by chemical vapor deposition method. Titanium silicide nanowires include nanowires, nanonails, Rocket-shaped nanowires in the TiSi crystal phase;

[0020] 2) Depositing a layer of 2 μm amorphous silicon film layer on the titanium silicide film and titanium silicide nanowire composite structure prepared in step 1) by plasma chemical vapor deposition at 13.56MHZ;

[0021] 3) Annealing and heat-treating the amorphous silicon thin film layer prepared in step 2) at 400°C for 2 hours, so that the titanium silicide nanowires induce the crystallization of the amorphous silicon thin film layer into a polycrystalline silicon thin film layer with large grains, and finally obtain figure 1 Large grain polysilicon thin film shown.

Embodiment 3

[0023] 1) Tin oxide transparent conductive glass (F-SNO 2 ) is the substrate, and the titanium silicide nanowires are prepared on the substrate 1 by the solid-state reaction method. 2 crystal phase;

[0024] 2) Depositing a 3 μm amorphous silicon film layer on the titanium silicide nanowire prepared in step 1) by magnetron sputtering;

[0025] 3) The amorphous silicon thin film prepared in step 2) is annealed and heat-treated at 400°C for 2 hours, so that the titanium silicide nanowire induces the crystallization of the amorphous silicon thin film layer into a polycrystalline silicon thin film layer with large grains, and finally obtains figure 1 Large grain polysilicon thin film shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com