Nylon 6 slices for superfine sea-island fibers and manufacturing method thereof

A technology for sea-island fibers and a manufacturing method, which are applied in the field of nylon 6 slices for ultra-fine sea-island fibers and their manufacturing fields, can solve the problems affecting the uniformity of nylon 6 ultra-fine sea-island fibers, cannot guarantee the stability of melt viscosity, and the structure of ultra-fine sea-island fibers. Changes and other problems, to achieve the effect of reasonable ratio, good melt viscosity matching, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add adipic acid, water, diaminodiphenylmethane, and isophthaloyldipiperidinamide in a ratio of 3:50:4.6:20, and melt them in a stainless steel container with a stirrer at 92-95°C, and then stir evenly. A mixed solution of additives is prepared.

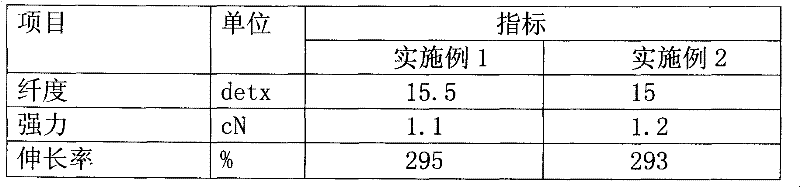

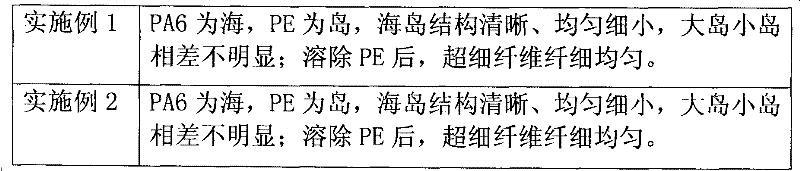

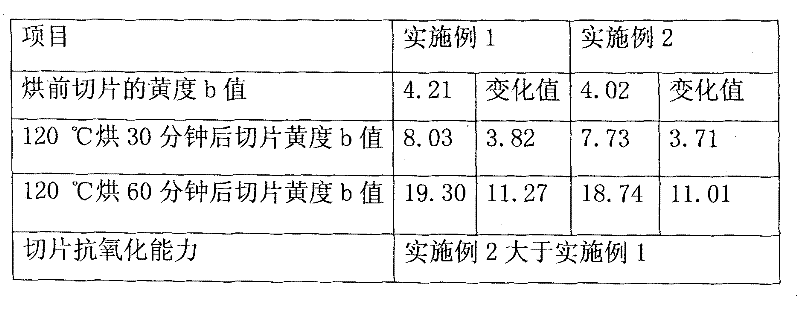

[0014] The mixed solution of caprolactam solution and the above-mentioned additives is measured by a metering pump at a ratio of 1000:8, and then fed into a continuous polymerization reaction vessel for pre-pressurization polymerization-depressurization polymerization through a static mixer to carry out polymerization reaction. Under the conditions of pre-polymerization temperature 250-270°C and post-polymerization temperature 230-250°C, polymerize for 13-17 hours to obtain nylon 6 resin for ultra-fine island-in-the-sea fibers, and then the polymerized melt is continuously extruded into strips through a melt metering pump , pelletizing, continuous extraction, and continuous nitrogen drying to obtain nylon 6 slices for ultrafine...

Embodiment 2

[0016] Add adipic acid, water, diaminodiphenylmethane, and isophthaloyl dipiperidinium in a ratio of 2:50:5.5:30, and melt in a stainless steel mixing vessel with a stirrer at 92-95°C, then stir evenly , to prepare a mixed solution of additives.

[0017] A certain amount of caprolactam solution and the above auxiliary agent mixed solution are metered by a metering pump at a ratio of 1000:8.9, and then put into a continuous polymerization reactor for pre-pressurization polymerization-decompression polymerization polymerization through a static mixer to carry out polymerization reaction. Under the conditions of pre-polymerization temperature 250-270°C and post-polymerization temperature 230-250°C, polymerize for 13-17 hours to obtain nylon 6 resin for ultra-fine island-in-the-sea fibers, and then the polymerized melt is continuously extruded into strips through a melt metering pump , pelletizing, continuous extraction, and continuous nitrogen drying to obtain nylon 6 slices for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com