Polylactic acid-glycolic acid copolymer particle bracket for injection and manufacturing method thereof

A glycolic acid copolymer, glycolic acid technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of flow in the injection site, non-biodegradability, and inability to apply to plastic parts, and achieve the effect of promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

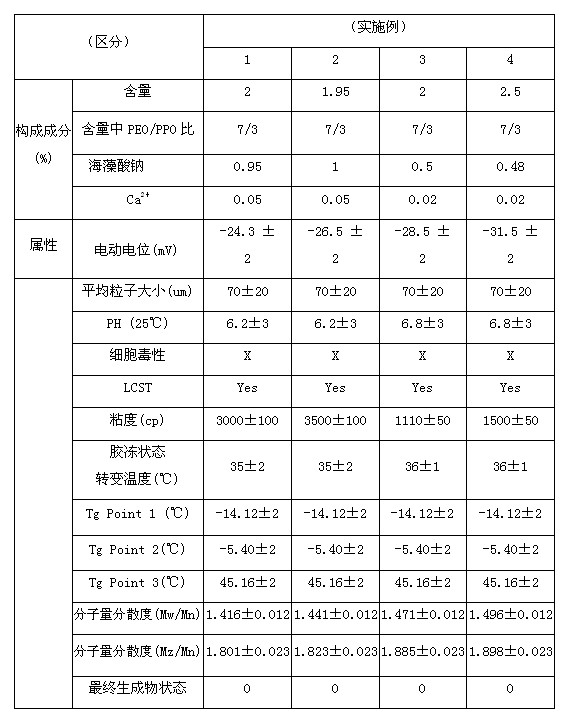

Embodiment 1

[0040] The polylactic acid-glycolic acid copolymer particle scaffold for injection is mainly composed of the following components in weight ratio: matrix 0.8, temperature-sensitive auxiliary agent 3, wherein the matrix is a biodegradable polymer composed of polylactic acid-glycolic acid PLGA, a temperature-sensitive auxiliary agent, consists of the following components by weight ratio: polyoxyethylene and polyoxypropylene triblock copolymer 2, non-toxic degradable sodium alginate-based biocompatible high molecular polymer 0.95, Ca 2+ Ion 0.05, Polyoxyethylene and Polyoxypropylene Triblock Copolymer Composed of Polyoxyethylene and Polyoxypropylene Triblock Copolymer in a ratio of Polyoxyethylene to 70% Polymer and Polyoxyethylene and Polyoxypropylene Triblock Copolymer The ratio of polyoxyethylene in the block copolymer was 80% of the polymer composition. The particle average molecular weight of the biodegradable particle scaffold is 90,000-110,000, and the average particle ...

Embodiment 2

[0055] Polylactic acid-glycolic acid copolymer particle scaffold for injection, which is mainly composed of the following components in weight ratio: matrix 1, temperature-sensitive auxiliary agent 3, wherein the matrix is a biodegradable polylactic acid-glycolic acid composed of Polymer PLGA, the temperature-sensitive auxiliary agent consists of the following components by weight ratio: polyoxyethylene and polyoxypropylene triblock copolymer 2.5, non-toxic degradable sodium alginate-based biocompatible polymer polymer 0.48, Ca 2+ Ionic 0.02, Polyoxyethylene and Polyoxypropylene Triblock Copolymer Composed of Polyoxyethylene and Polyoxypropylene Triblock Copolymer with a Polyoxyethylene ratio of 70% Polymer and Polyoxyethylene and Polyoxypropylene Triblock Copolymer The ratio of polyoxyethylene in the block copolymer was 80% of the polymer composition. The particle average molecular weight of the biodegradable granular scaffold is 90,000-110,000, and the average particle si...

Embodiment 3

[0070] Polylactic acid-glycolic acid copolymer particle scaffold for injection, which is mainly composed of biodegradable polymers, wherein the biodegradable polymers include components in weight ratio: matrix 0.9, temperature-sensitive auxiliary agent 3, wherein , the matrix is a biodegradable polymer PLGA composed of polylactic acid-glycolic acid, and the temperature-sensitive auxiliary agent includes components in the following weight ratio: polyoxyethylene and polyoxypropylene triblock copolymer 1.95, non-toxic Degradability of alginate-based biocompatible polymer 1.0, Ca 2+ Ion 0.05, Polyoxyethylene and Polyoxypropylene Triblock Copolymer Composed of Polyoxyethylene and Polyoxypropylene Triblock Copolymer in a ratio of Polyoxyethylene to 70% Polymer and Polyoxyethylene and Polyoxypropylene Triblock Copolymer The ratio of polyoxyethylene in the block copolymer was 80% of the polymer composition. The particle average molecular weight (Mw) of the biodegradable granular sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com