Composition for producing metal film, method for producing metal film, and method for producing metal powder

A manufacturing method and metal film technology, applied in the direction of metal/alloy conductors, metal processing equipment, cable/conductor manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] 0.06 g of triruthenium dodecacarbonyl was dissolved in a liquid mixed with 12.5 mL of 1,3-butanediol and 12.5 g of 1,4-cyclohexanediol to prepare a solution. After mixing 0.1 g of this solution with 0.04 g of cuprous nitride (I) (fine particles obtained by a spray pyrolysis method: average particle diameter: 30 nm), printing was performed on a polyimide substrate by a screen printing method. Then, in a nitrogen atmosphere, the temperature was raised at a rate of 100° C. / minute, and heated at 200° C. for 1 hour. The obtained film had a film thickness of 12 μm and a resistivity of 1700 μΩcm.

Embodiment 2

[0101] Except for heating at 160° C., the same operation as in Example 1 was carried out, and the obtained film had a film thickness of 13 μm and a resistivity of 3800 μΩcm.

Embodiment 3

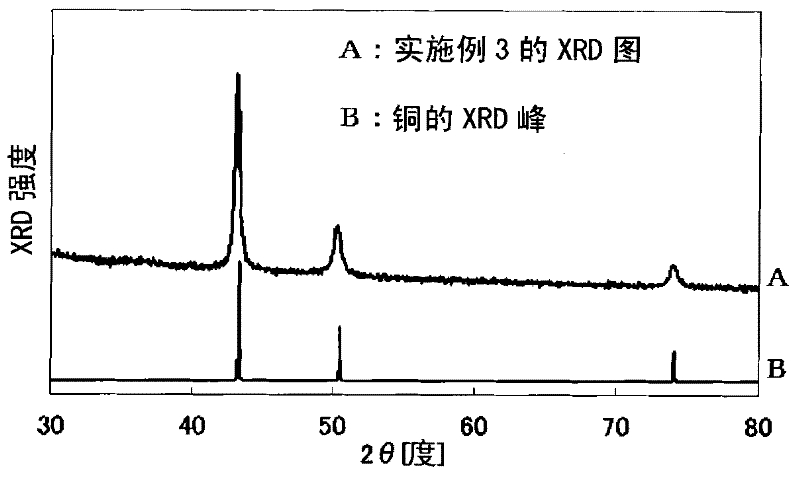

[0103] Except mixing 0.018 g of epoxy resin (manufactured by Toagosei Co., Ltd., grade: AS-60) in the solution of Example 1, the same operation as Example 1 was carried out. The film thickness of the obtained film was 10 μm, and the resistance The ratio is 350 μΩcm. The X-ray diffraction pattern of the obtained film was measured, and as a result, it was confirmed that figure 1 Diffraction peaks from metallic copper are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com