Piezoelectric film, piezoelectric device, liquid ejecting device, and method for producing piezoelectric film

一种压电薄膜、液体的技术,应用在制备所述压电薄膜领域,能够解决裂纹、PZT薄膜裂纹、耐久性下降等问题,达到防止形成缺陷、改善驱动耐久性、驱动耐久性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

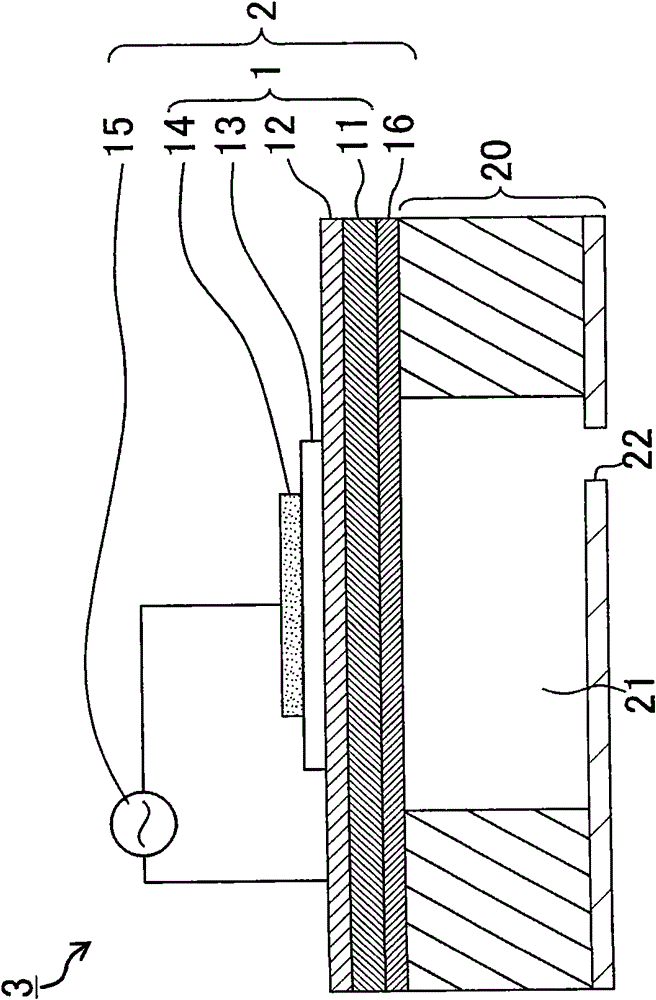

[0131] Using a sputtering method at a substrate temperature of 350° C., a Ti film with a thickness of 30 nm and an Ir film with a thickness of 150 nm were sequentially formed on an SOI substrate to obtain a lower electrode. A Nb-doped PZT piezoelectric thin film with a thickness of 4 μm was formed on this lower electrode. Formation of this thin film was performed under the following conditions.

[0132] >

[0133] Film forming device: RF sputtering device

[0134] Target: Pb 1.3 ((Zr 0.52 Ti 0.48 ) 0.88 Nb 0.12 ) O 3 Sintered body (amount of Nb occupying the B site: 12 mol%)

[0135] Substrate temperature: 475°C

[0136] Target-substrate (T-S) distance: 60mm

[0137] Film forming pressure: 0.30Pa

[0138] Film-forming gas: Ar / O 2 =97.5 / 2.5 (molar ratio)

[0139] Substrate potential Vsubstrate = -12V

[0140] After the start of film formation, the substrate potential V 基板 Set at +25V for 5 minutes to provide the perovskite layer as the initial layer.

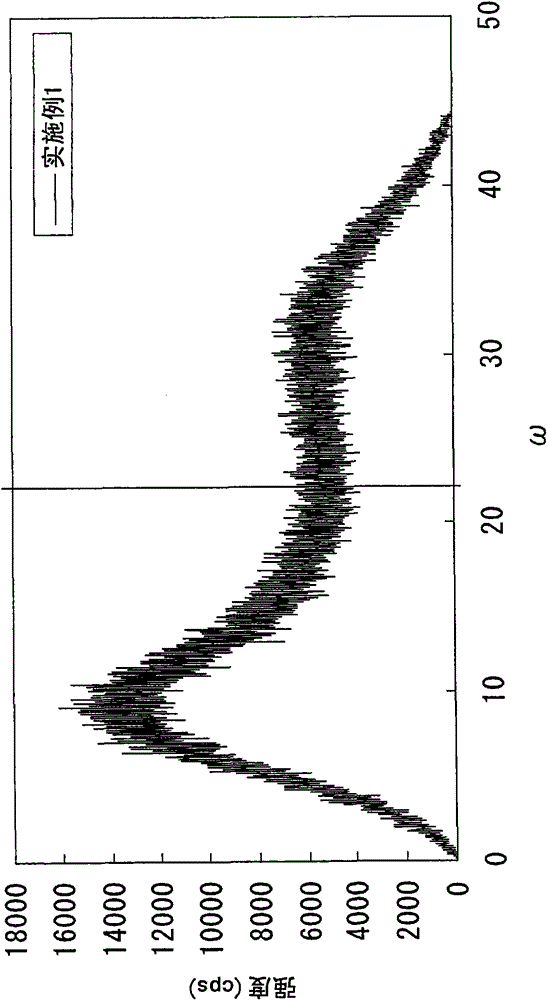

[0141] Af...

Embodiment 2-6

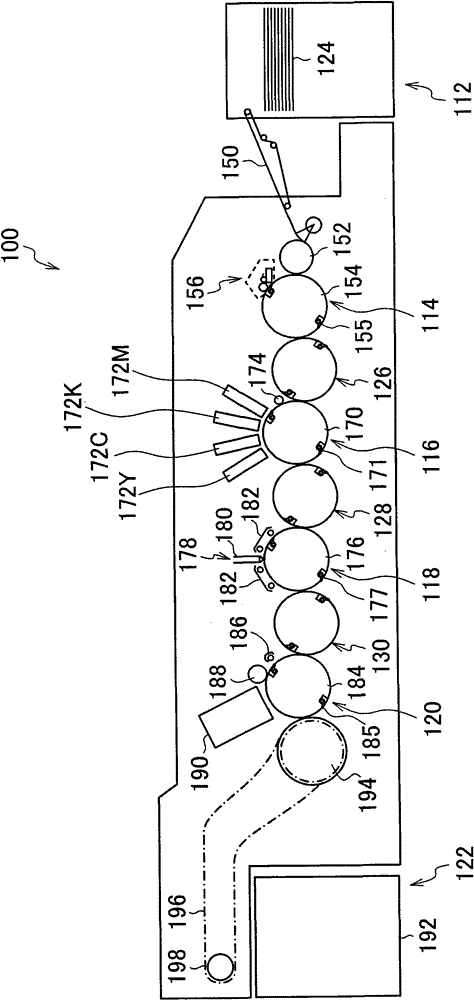

[0151] Using the same method as Example 1 in Figure 5 A piezoelectric thin film and an ink jet recording head were prepared under the conditions described, and the resulting piezoelectric thin film and ink jet recording head were evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com