Method for mfg. high-pressure discharge lamp, high-pressure discharge lamp and lamp assembly

A technology of high-pressure discharge lamps and manufacturing methods, which is applied to the manufacture of discharge tubes/lamps, components of gas discharge lamps, discharge lamps, etc., and can solve the problem of unavailability, increase of lamp current, and increase of lamp voltage to a necessary level First-class problems, to achieve the effect of suppressing composition changes, effective compressive strength, and high manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

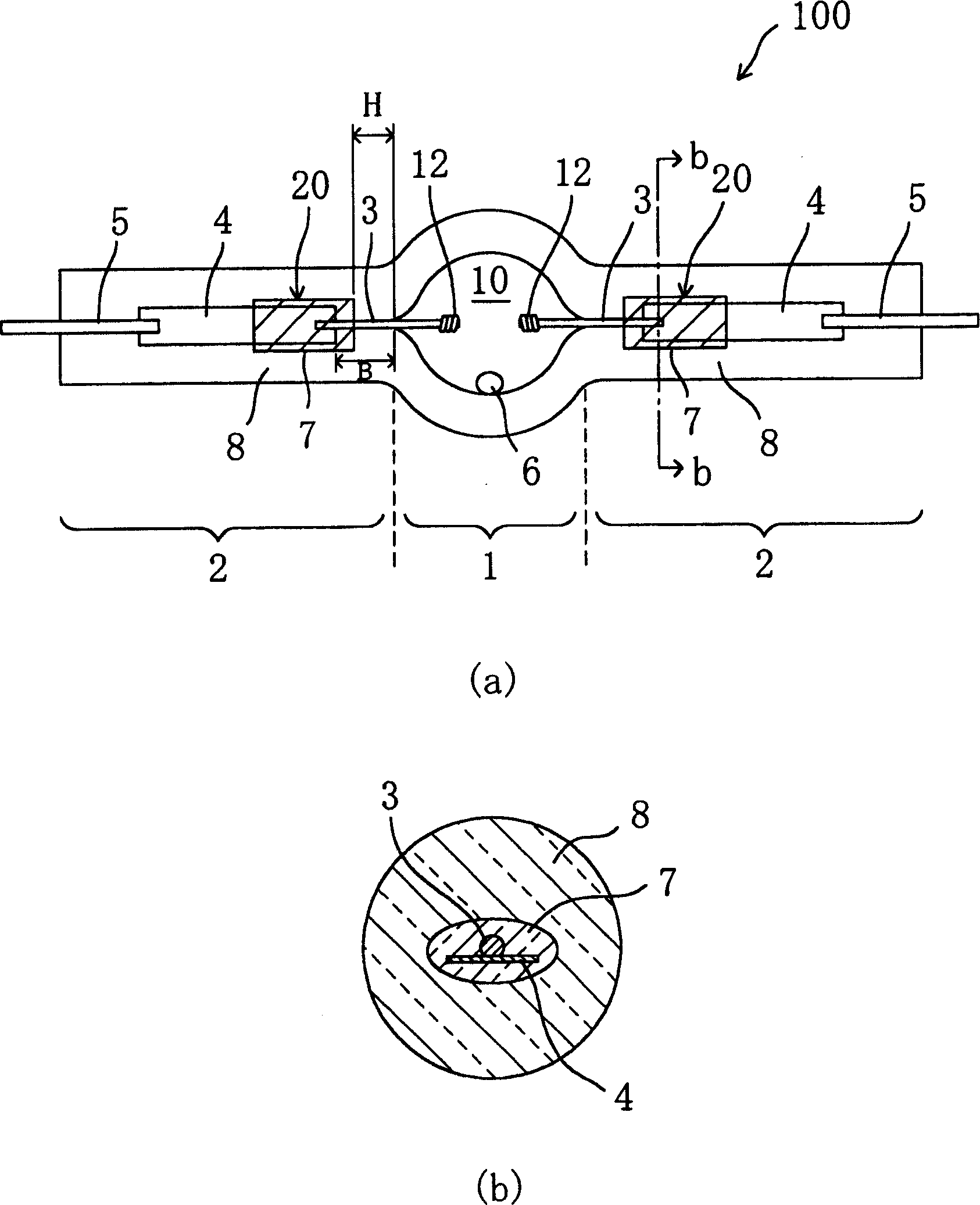

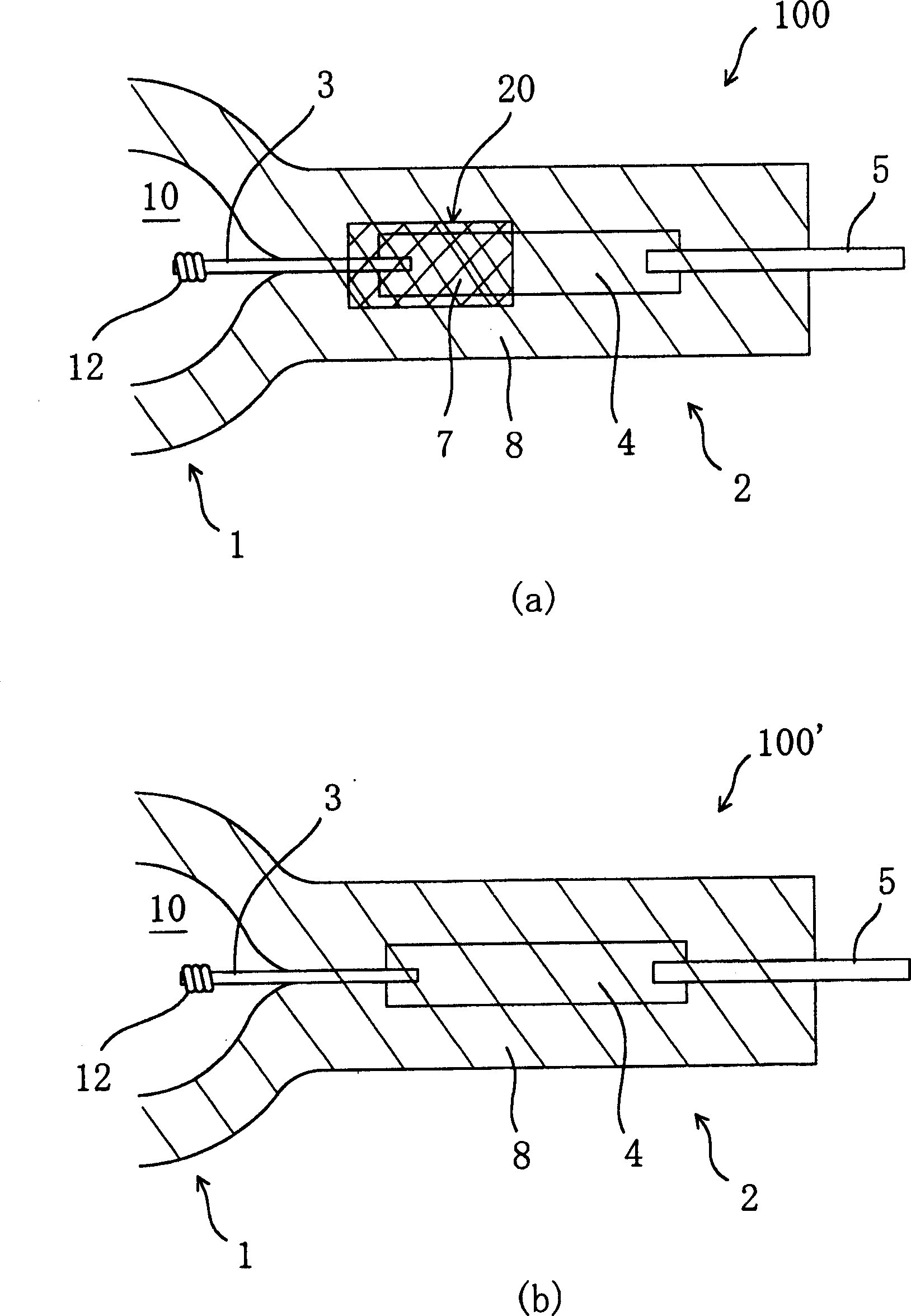

[0089] In the high-pressure discharge lamp according to the embodiment of the present invention, mercury bromide (HgBr 2 ), which is the same as figure 1 The high pressure discharge lamps shown are different, figure 1 If the high-pressure discharge lamp shown is to be filled with a halogen precursor (for example, CH 2 Br 2 , HBr) or a halogen element (for example, Br), the type is not particularly limited, or depending on the situation, the halogen element may not be enclosed. Another point, since the structure is basically the same as figure 1 are the same as shown, so refer to figure 1 A high-pressure discharge lamp according to an embodiment of the present invention will be described. In addition, for the convenience of description, the symbol of the high-pressure discharge lamp of this embodiment is designated as "100", and the number is omitted or simplified. figure 1 Represents the structure and repeated parts.

[0090] The lamp 100 of this embodiment is a do...

Embodiment approach 2

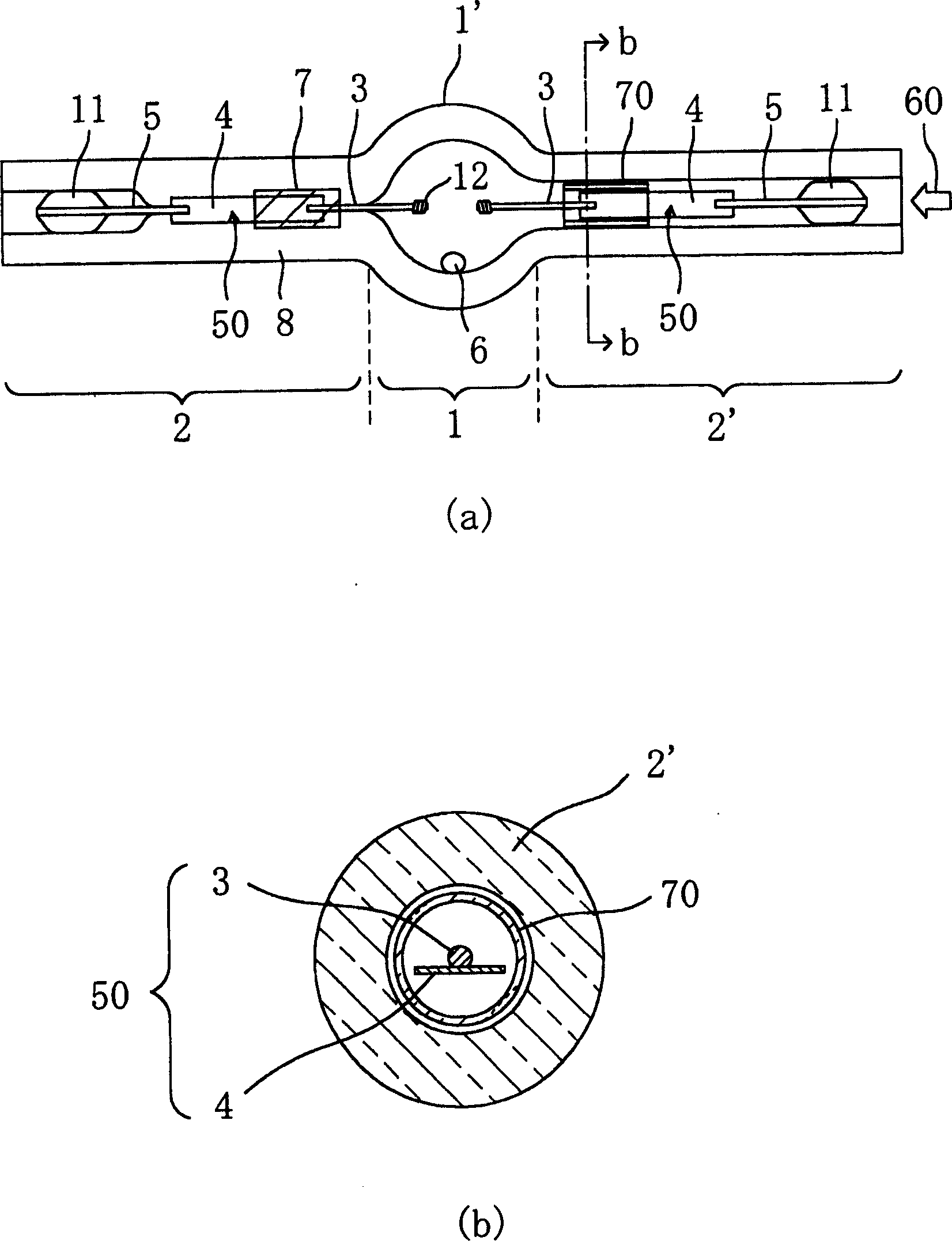

[0137] refer to Figure 7 , the high-pressure discharge lamp according to Embodiment 2 of the present invention will be described. Figure 7 The structure of the high-pressure discharge lamp 200 of this embodiment is shown schematically. Mercury bromide (HgBr 2 ) as the halogen element precursor is the same as the high-pressure discharge lamp of Embodiment 1 above. It should be mentioned that in this embodiment and the above-mentioned Embodiment 1, mercury bromide (HgBr 2 ) are omitted in the figure.

[0138] Such as Figure 7 As shown, in order to further improve the withstand voltage strength of the lamp 100 in this embodiment, it is preferable to Figure 7 Like the lamp 200 shown, a metal film (for example, a Pt film) 30 is formed on at least a part of the surface of the part of the electrode rod 3 buried in the sealing part 2 . It should be noted that the metal film 30 may be formed of at least one metal selected from the element group consisting of Pt, Ir, Rh, Ru, a...

other Embodiment approach

[0154] In the above-mentioned embodiments, a mercury lamp using mercury as a light-emitting substance has been described as an example of a high-pressure discharge lamp. The present invention is also applicable to any high-pressure discharge lamp having a structure in which the airtightness of the arc tube is maintained by the sealing portion. For example, the present invention is also applicable to a metal halide lamp or a high-pressure discharge lamp such as xenon that seals a metal halide. Because for metal halide lamps, etc., the higher the withstand voltage, the better. In other words, it is because by preventing air leakage and preventing cracks, a lamp with high reliability and long life can be obtained. When the structure described in the above-mentioned embodiment is applied to a metal halide lamp in which not only mercury but also metal halide is sealed, the following effects can be obtained. In other words, by providing the second glass part 7, the adhesion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com