Fuel cell and its fabrication method

A fuel cell and electrolyte technology, which is applied in the direction of fuel cells, fuel cell additives, fuel cell components, etc., can solve problems such as the difficulty of strengthening the frame to be bonded to electrodes, and achieve suppression of inhomogeneity, deformation, and composition changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

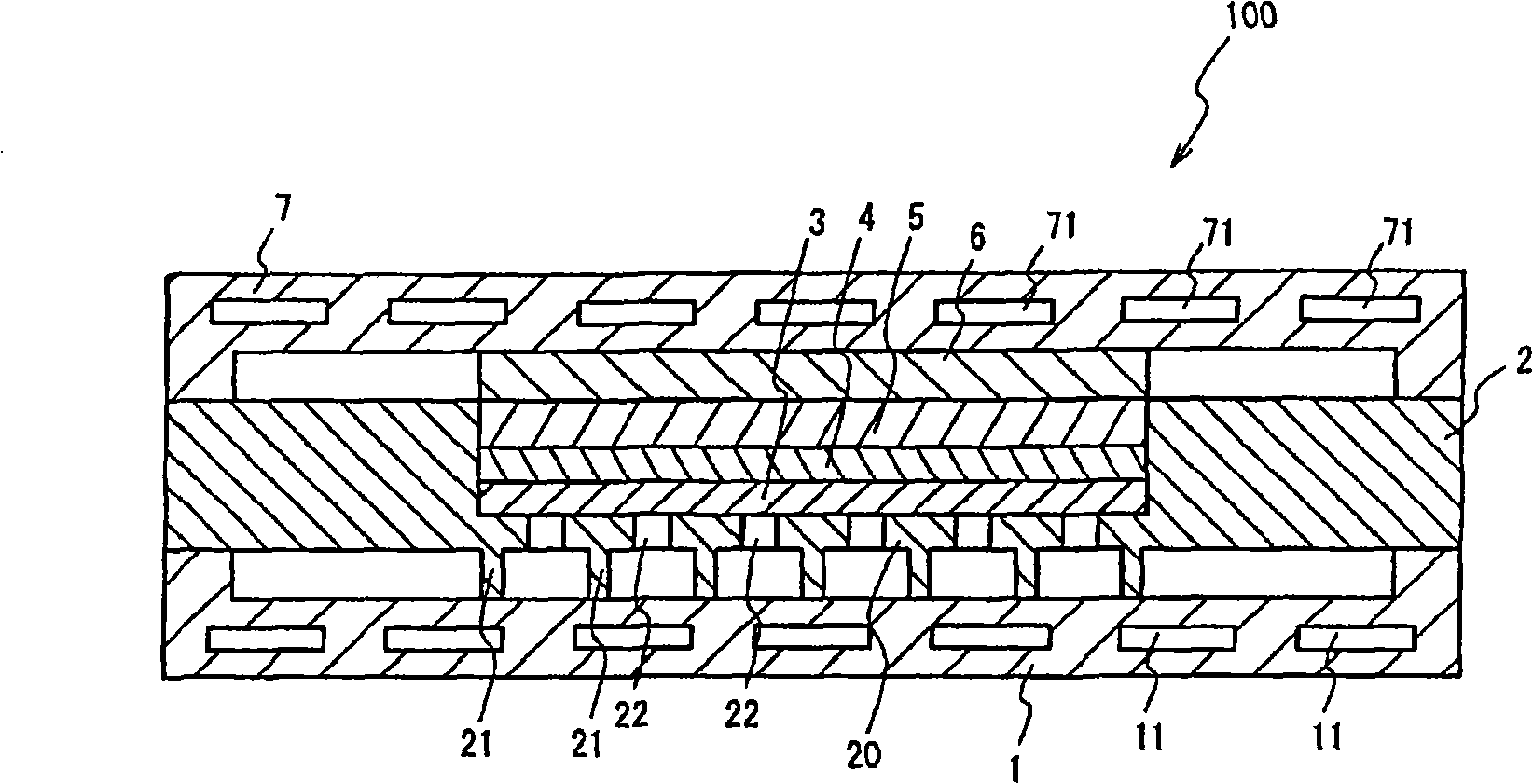

[0025] figure 1 A schematic cross-sectional view of a fuel cell 100 according to a first embodiment of the present invention is shown. In this embodiment, a hydrogen permeable membrane fuel cell is used as the fuel cell. Here, the hydrogen permeable membrane fuel cell has a hydrogen permeable membrane. The hydrogen permeable membrane is made of a hydrogen permeable metal. A hydrogen permeable membrane fuel cell has a structure in which an electrolyte having proton conductivity is provided on a hydrogen permeable membrane. A part of hydrogen supplied to the anode is converted into protons through a catalytic reaction. Protons are conducted in the electrolyte having proton conductivity, react with oxygen supplied to the cathode, and are converted into water. Electricity is generated from this. The structure of the fuel cell 100 will be described below.

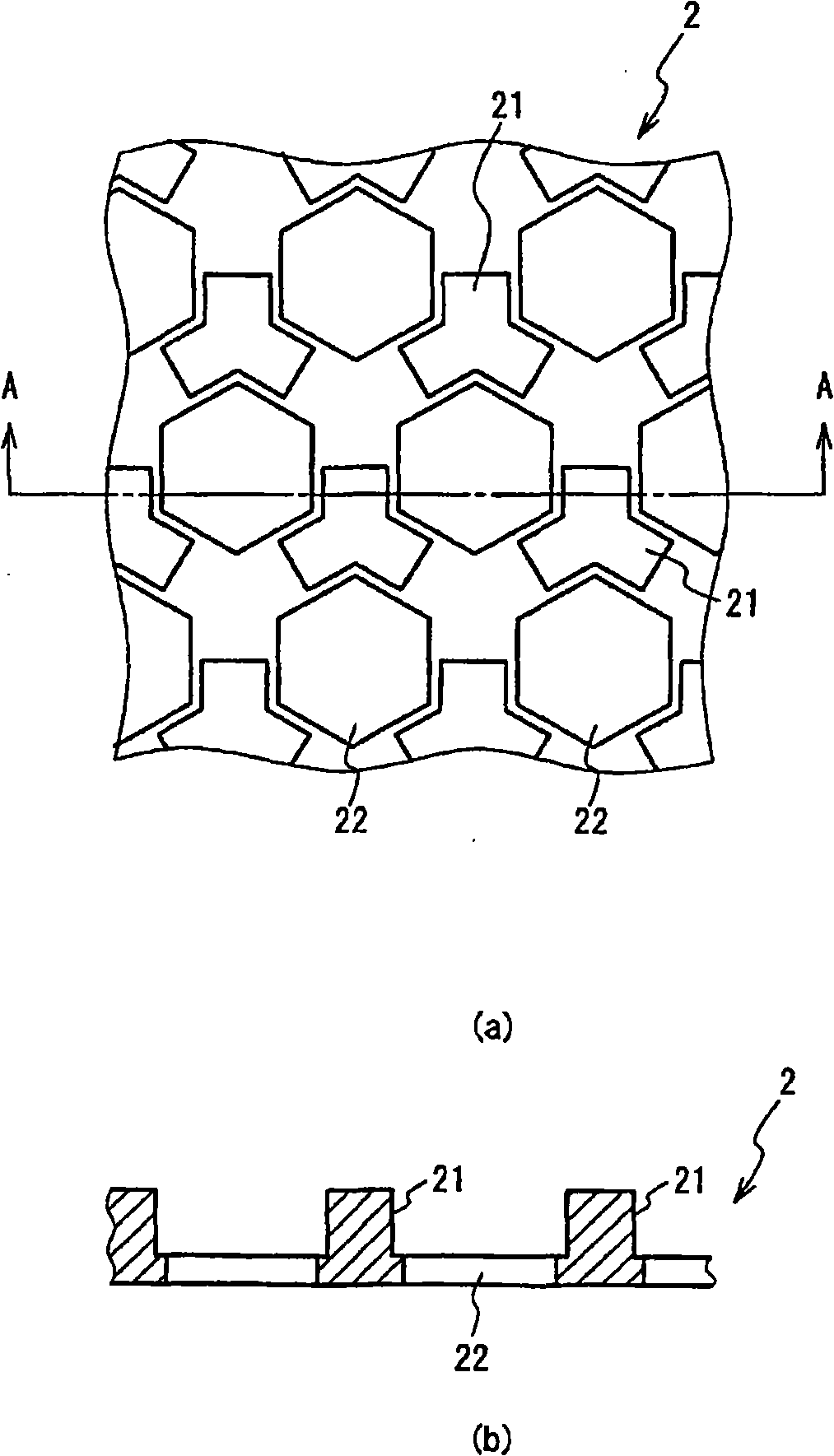

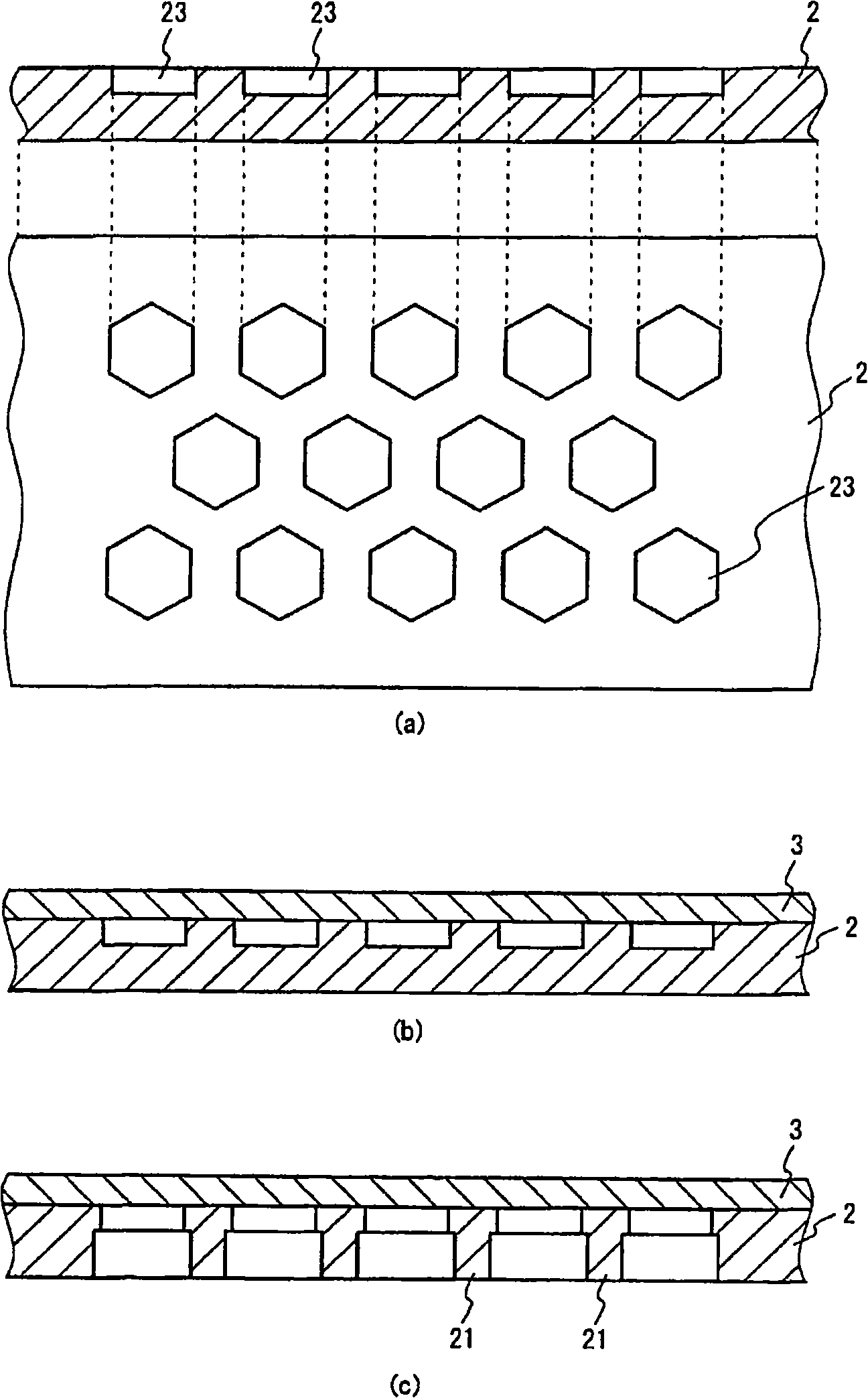

[0026] Such as figure 1 As shown, the fuel cell 100 has separators 1 and 7 , a reinforcing frame 2 , a hydrogen permeab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com