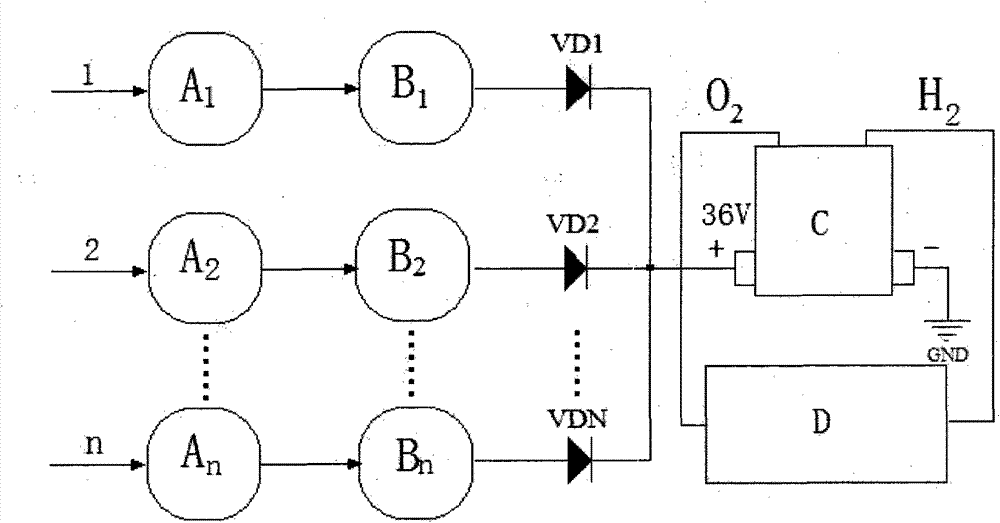

Low-cost hydrogen production method by water electrolysis capable of occurring over a wide power supply voltage range

A technology of power supply voltage and water electrolysis, applied in the electrolysis process, electrolysis components, energy input, etc., can solve the problems of low commercial practicability, limited storage conditions, and high electricity costs, and achieves solutions to liquid level balance problems, storage problems, and improvement. The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In this embodiment, the maximum allowable power of each energy processing circuit is 3000W.

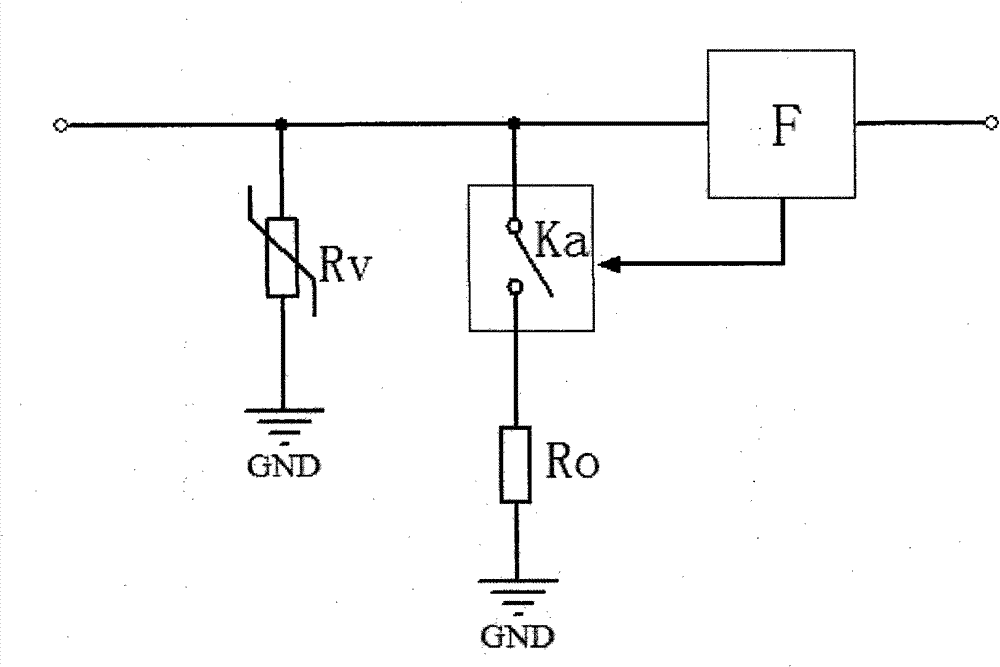

[0026] Power input devices Power input devices such as figure 2As shown, each energy processing circuit is required to be equipped with one. It can be seen from Figure 2 that the device is equipped with a lightning protection circuit and an overcurrent protection circuit (F). When a lightning strike occurs at the input end, the lightning protection varistor (Rv) connected in parallel to the input end is broken down, and the The voltage is clamped at the breakdown voltage of the varistor (Rv), which effectively prevents the possibility of damage to the circuit connected behind. When the input power is greater than the maximum power that the reverse voltage regulator circuit can handle, the overcurrent protection circuit (F) operates, and the dummy load (Ro) is connected to the dummy load (Ro) through the electronic switch (Ka) in a pulse width modulation manner to consume the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com