High-power LED (Light Emitting Diode) encapsulating structure

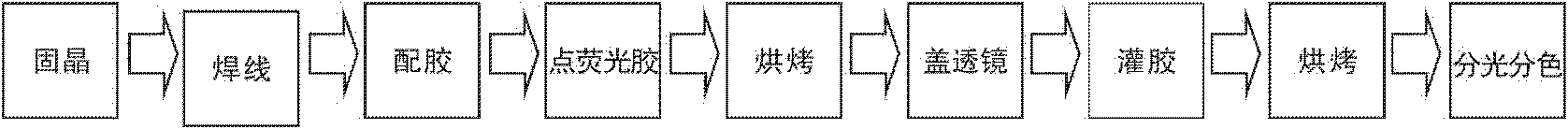

A LED packaging, high-power technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor particle fluidity, serious powder agglomeration, irregular shape, etc., to repair the light spot, solve the problem of light spot, improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

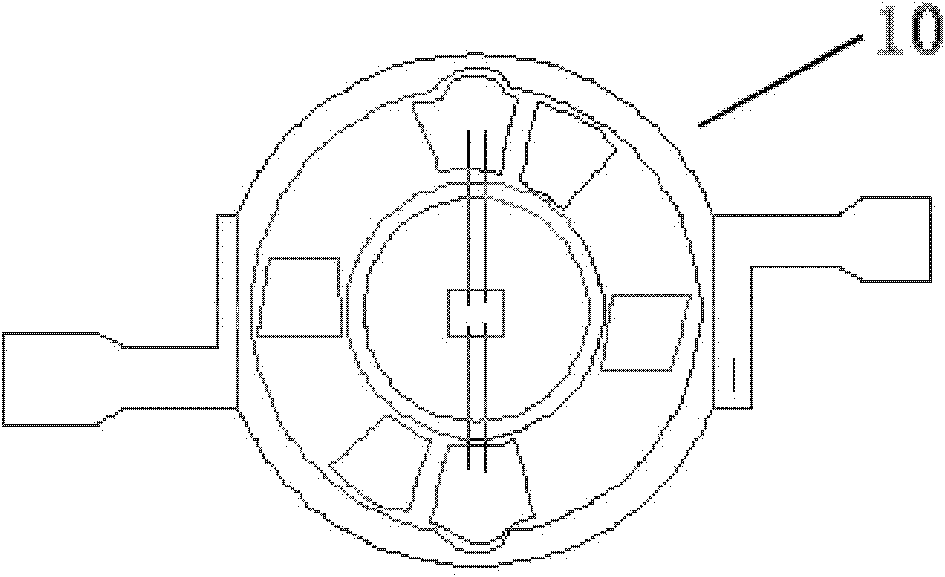

[0050]The angle α is 40°, the depth h of the bowl is 0.3mm, the LED light-emitting chip 1 is fixed on the bracket 10 with silver glue, and baked and heated to cure, wherein the chip size is 24mil×24mil; then the gold wire 2 is welded on the chip 1 Positive and negative poles; then, the fluorescent glue 7 is coated on the surface of the chip 1. In order to effectively suppress the heterochromatic aperture or light spot formed by refraction after the light passes through the lens 9, the thickness of the coating on the surface of the chip 1 is greater than that on the side of the chip, resulting in Apply fluorescent glue 7 to form an arc, the arc of which is consistent with the arc of the covered lens, and bake and shape, cover the lens 9 above the bracket, inject filling silica gel 8, and bake and shape. Magnified view of phosphor surface coating and lens coverage see Figure 7 .

Embodiment 2

[0052] The angle α is 45°, the depth h of the bowl is 0.35mm, the light-emitting chip 1 is fixed on the support 10 with silver glue, and baked and heated to cure, wherein the chip size is 38mil×38mil; then the gold wire 2 is welded on the front of the chip. , Negative electrode; then apply fluorescent glue on the surface of the chip, in order to effectively suppress the heterochromatic aperture or light spot formed by refraction after the light passes through the lens, the thickness of the coating on the surface of the chip is greater than that on the side of the chip, causing the coating of fluorescent glue 7 to form The arc shape is consistent with the arc of the covered lens, and it is baked and formed. Cover the lens 9 above the support, inject filling silica gel 8, and carry out baking molding.

Embodiment 3

[0054] The angle α is 50°, the depth h of the bowl is 0.45mm, the light-emitting chip 1 is fixed on the support 10 with silver glue, and baked and heated to cure, wherein the chip size is 45mil×45mil; , Negative electrode; then apply fluorescent glue on the surface of the chip, in order to effectively suppress the heterochromatic aperture or light spot formed by refraction after the light passes through the lens, the thickness of the coating on the surface of the chip is greater than that on the side of the chip, causing the coating of fluorescent glue 7 to form The arc shape is consistent with the arc of the covered lens, and it is baked and formed. Cover the lens 9 above the support, inject filling silica gel 8, and carry out baking molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com