Method for manufacturing fiber self-adhesion elastic bandage

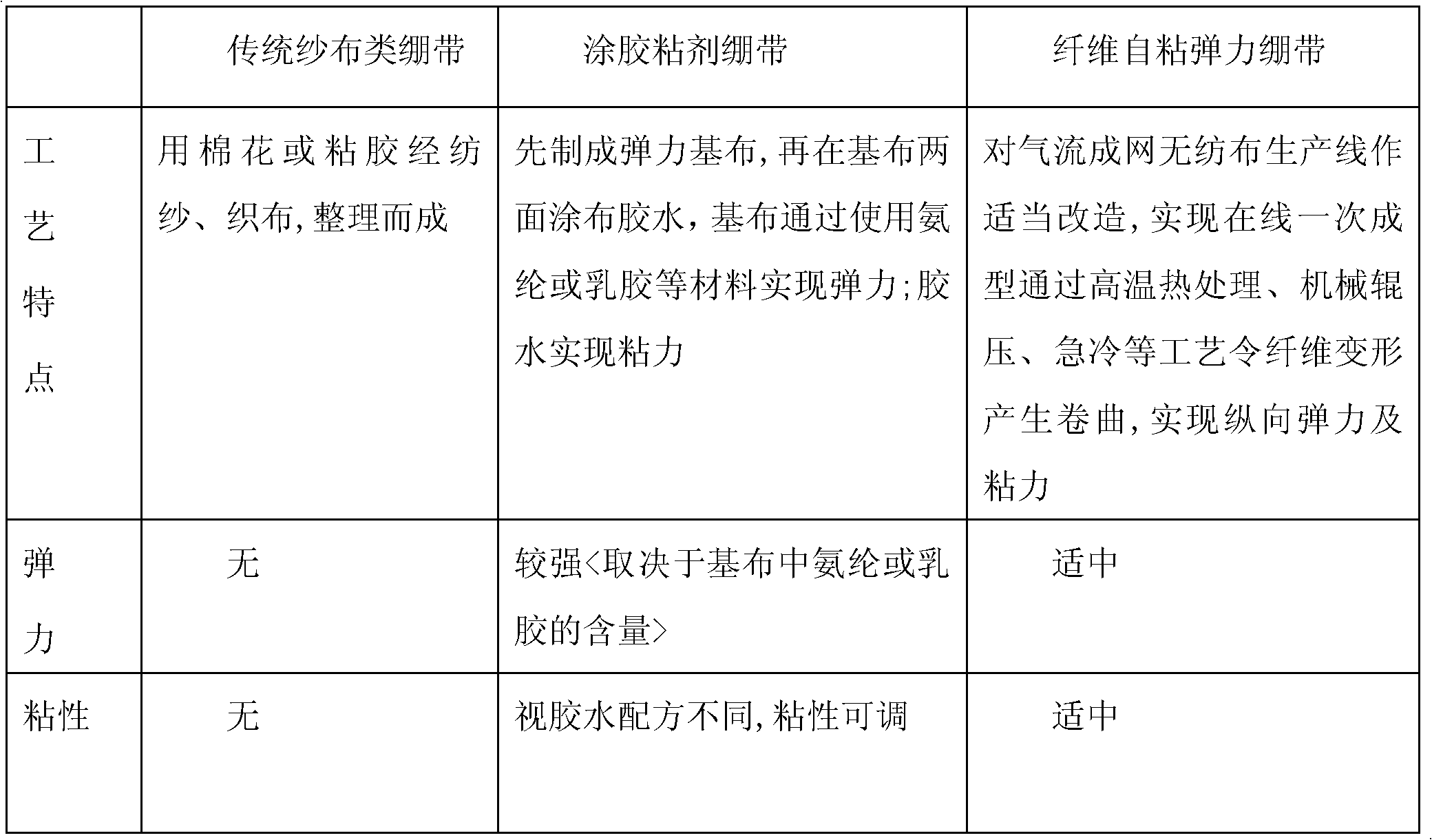

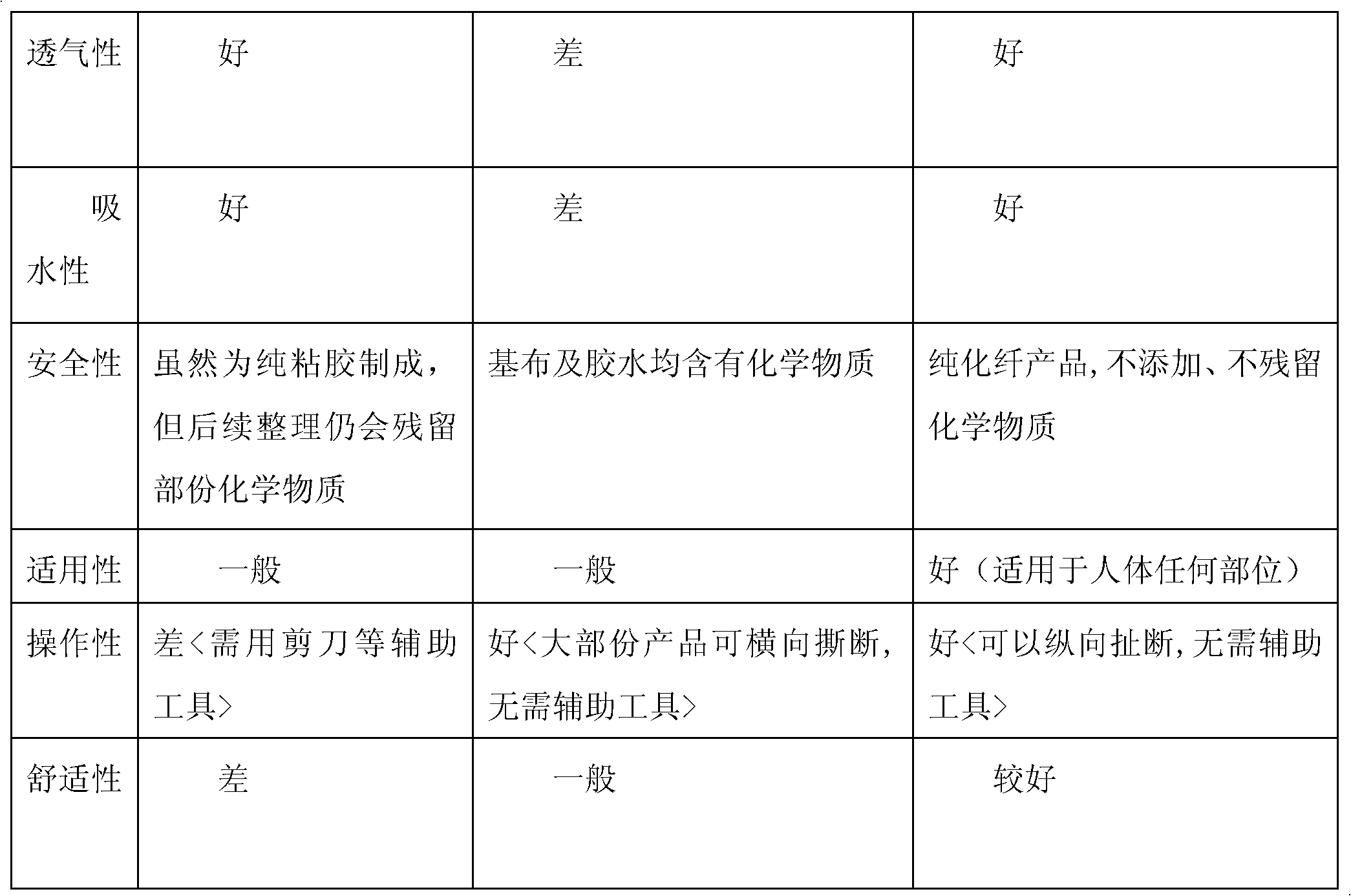

An elastic bandage and the technology of its manufacturing method are applied in the fields of bandages, medical science, textiles and paper making, etc. It can solve the problems of affecting blood circulation, skin discomfort, hard surface, etc., and achieve the effect of simple process, moderate elasticity and soft surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

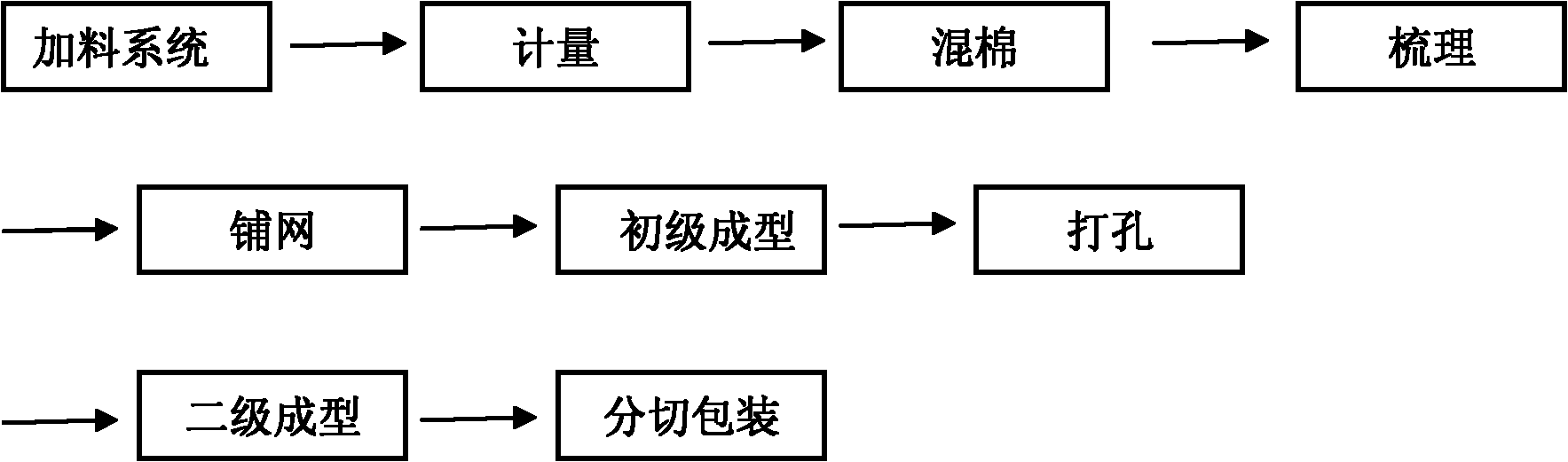

[0029] The fiber self-adhesive elastic bandage of the present invention is prepared according to the following steps:

[0030] (1) Raw material preparation: select PP fiber (Hubei Botao Synthetic Fiber Co., Ltd., specification 2.5d / 5.0mm), after the feeding system has been metered, enter the cotton blending machine for blending, and process fibers of various lengths and deniers Fully mixed, the mixed raw materials are taken out by the feet and sent to the next process by the fan;

[0031] (2) Carding: make the fibers form a uniform fiber web; using a carding machine, use various types of rotating card clothing and different card clothing rotation speeds and directions to fully card the fibers, remove impurities, and achieve parallel straightening In the state of single fiber, the fibers are fully mixed, and finally a uniform fiber network is formed.

[0032] (3) Cross-lapping: use a cross-lapping machine (cross-lapping device) to spread the fiber web reciprocally and evenly, ...

Embodiment 2

[0038] The fiber self-adhesive elastic bandage of the present invention is prepared according to the following steps:

[0039] (1) Raw material preparation: select PET fiber with low melting point (Hubei Yizheng Chemical Fiber Co., Ltd., specification 20d / 3F), enter the cotton blending machine after metering in the feeding system for blending, and fully mix fibers of various lengths and deniers , the mixed raw materials are taken out by the feet and sent to the next process through the fan;

[0040] (2) Carding: make the fibers form a uniform fiber web; using a carding machine, use various types of rotating card clothing and different card clothing rotation speeds and directions to fully card the fibers, remove impurities, and achieve parallel straightening In the state of single fiber, the fibers are fully mixed, and finally a uniform fiber network is formed.

[0041](3) Cross-lapping: use a cross-lapping machine (cross-lapping device) to spread the fiber web reciprocally an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com