Method for preparing flame-retardant anti-dripping copolyester fibers

A technology of copolyester and anti-droplet, which is applied in the field of copolyester fiber, can solve the problems of difficult peeling and dispersion, and achieve good application prospects, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

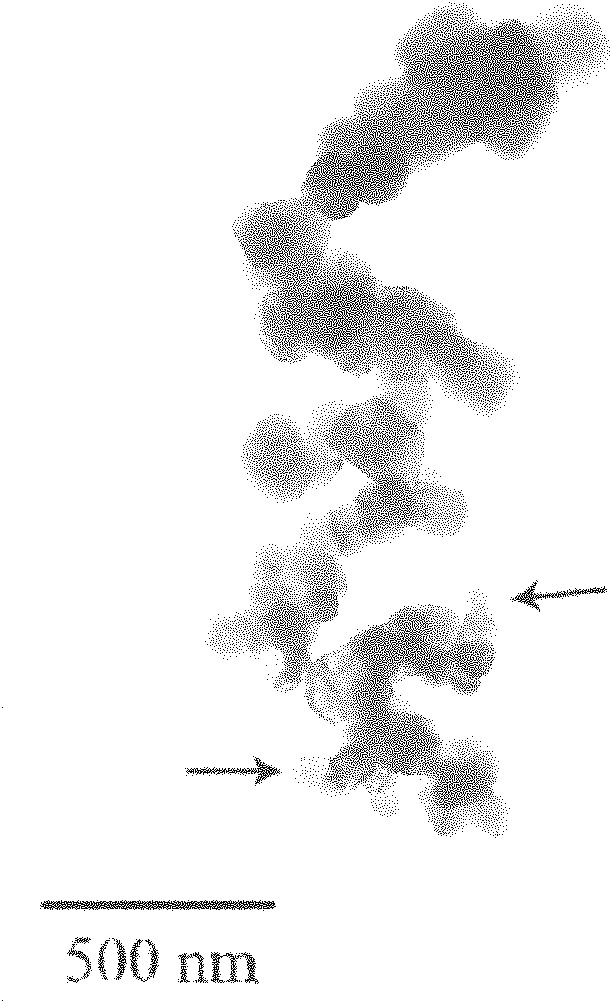

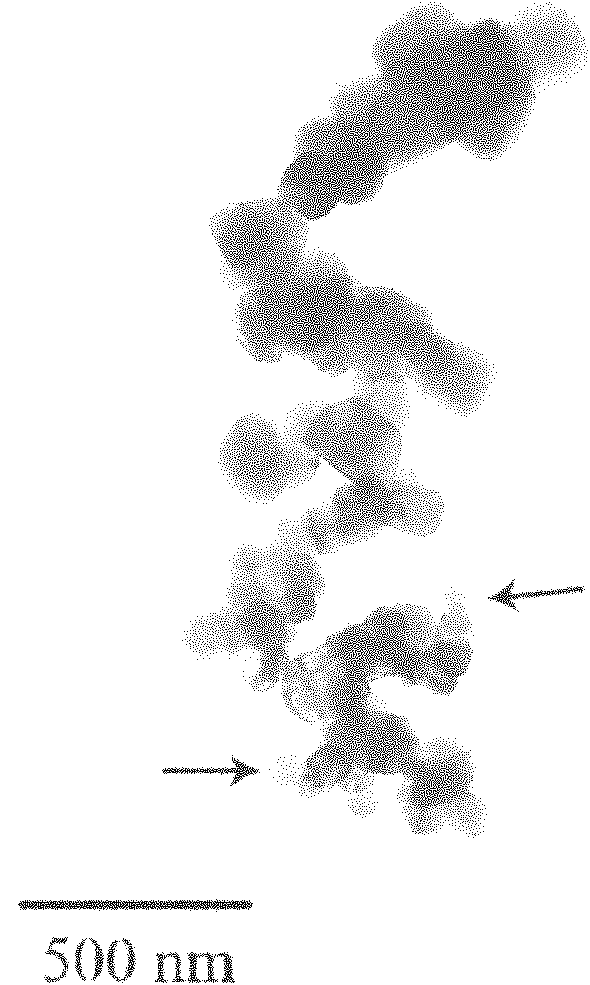

Image

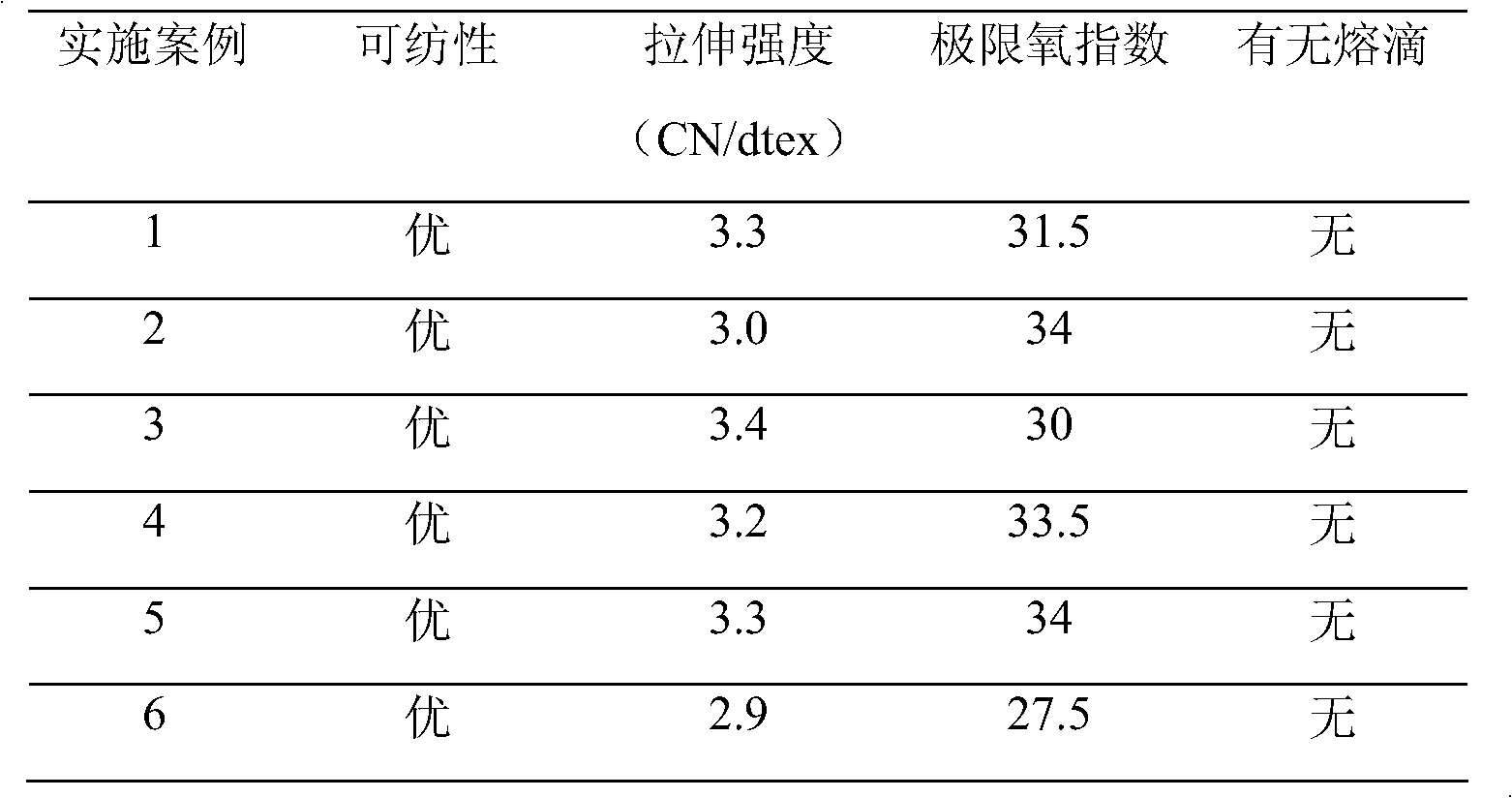

Examples

Embodiment 1

[0025] Add 5 grams of Laponite, an inorganic clay, into 110 milliliters of water, and stir at a high speed for 1 hour at room temperature, at which point the liquid becomes clear and transparent. Then add 35 milliliters of ethylene glycol, stir for 4 hours, and remove 80 milliliters of water in the mixed liquid by distillation under reduced pressure. Add this mixed solution to 250 grams of terephthalic acid, 100 milliliters of ethylene glycol and 32 grams of 2-carboxyethylphenylphosphinic acid, add 0.1 gram of ethylene glycol antimony as a catalyst, add 0.075 gram of triphenyl phosphate For heat stabilizer. The esterification reaction is carried out at 230°C and the pressure is 0.3 MPa, and then the polycondensation reaction is carried out under the high vacuum condition of 260°C to obtain flame-retardant and droplet-resistant copolyester chips. The resulting copolyester had an intrinsic viscosity of 0.56 and a melting point of 247°C.

[0026] The copolyester chip is melt-sp...

Embodiment 2

[0028] Add 7.5 grams of Laponite, an inorganic clay, into 160 milliliters of water, and stir at a high speed for 1 hour at room temperature, at which point the liquid becomes clear and transparent. Then add 50 milliliters of ethylene glycol, stir for 4 hours, and remove 100 milliliters of water in the mixed liquid by distillation under reduced pressure. Add this mixed solution to 250 grams of terephthalic acid, 100 milliliters of ethylene glycol and 40 grams of 2-carboxyethylphenylphosphinic acid, add 0.1 gram of ethylene glycol antimony as a catalyst, add 0.075 gram of triphenyl phosphate For heat stabilizer. The esterification reaction is carried out at 240°C and the pressure is 0.2 MPa, and then the polycondensation reaction is carried out under the high vacuum condition of 270°C to obtain flame-retardant and anti-droplet copolyester chips. The resulting copolyester had an intrinsic viscosity of 0.50 and a melting point of 241°C.

[0029] The copolyester chips were dried ...

Embodiment 3

[0031]Add 3 grams of Laponite, an inorganic clay, into 60 milliliters of water, and stir at a high speed for 1 hour at room temperature, at which point the liquid becomes clear and transparent. Then add 20 milliliters of ethylene glycol, stir for 4 hours, and remove 40 milliliters of water in the mixed liquid by distillation under reduced pressure. This mixed solution was added to 250 grams of terephthalic acid, 130 milliliters of ethylene glycol and 35 grams of 9,10-dihydro-9-oxa-10-phosphaphenanthrene, and 0.1 grams of ethylene glycol Cobalt is used as a catalyst, and 0.075 grams of triphenyl phosphate is added as a thermal stabilizer. The esterification reaction is carried out at 250°C and the pressure is 0.35 MPa, and then the polycondensation reaction is carried out under the high vacuum condition of 280°C to obtain flame-retardant and droplet-resistant copolyester chips. The resulting copolyester had an intrinsic viscosity of 0.54 and a melting point of 247°C.

[0032]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com