Production method of X70 hot-rolled medium plate for submerged pipeline

A production method and technology for submarine pipelines, which are applied in the field of low-carbon microalloyed steel production, can solve problems such as the disclosure of the chemical composition of steel plates and their production methods, and achieve comprehensive mechanical properties improvement, safety, and transverse and longitudinal strength and low-temperature toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] According to the production method of X70 hot-rolled medium and heavy plates for submarine pipelines of the present invention, a steel plate with a thickness of 25 mm is produced on a 4300 mm double-frame wide and heavy plate production line by using a 400 mm thick steel billet. The chemical composition of the billet is shown in Table 1, the controlled rolling and controlled cooling process is shown in Table 2, the strength properties are shown in Table 3, and the impact toughness of the steel plate at a series of temperatures is shown in Table 4.

[0024] The chemical composition (weight, %) of table 1 embodiment 1

[0025] C

Si

mn

P

S

Alt

Nb

Ti

Mo

Ni

Cr

Cu

0.062

0.19

1.53

0.009

0.0020

0.042

0.046

0.018

0.17

0.18

0.18

0.23

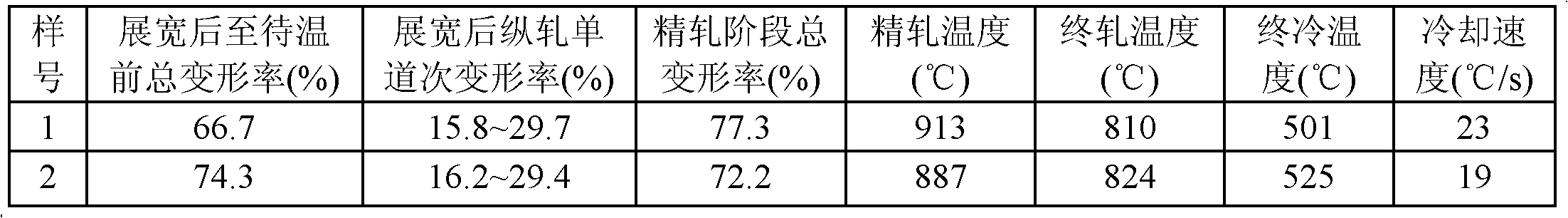

[0026] Table 2 Process system

[0027]

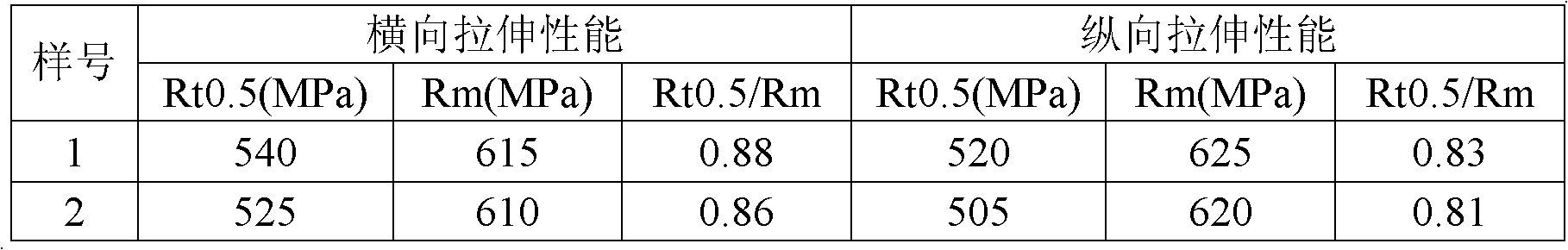

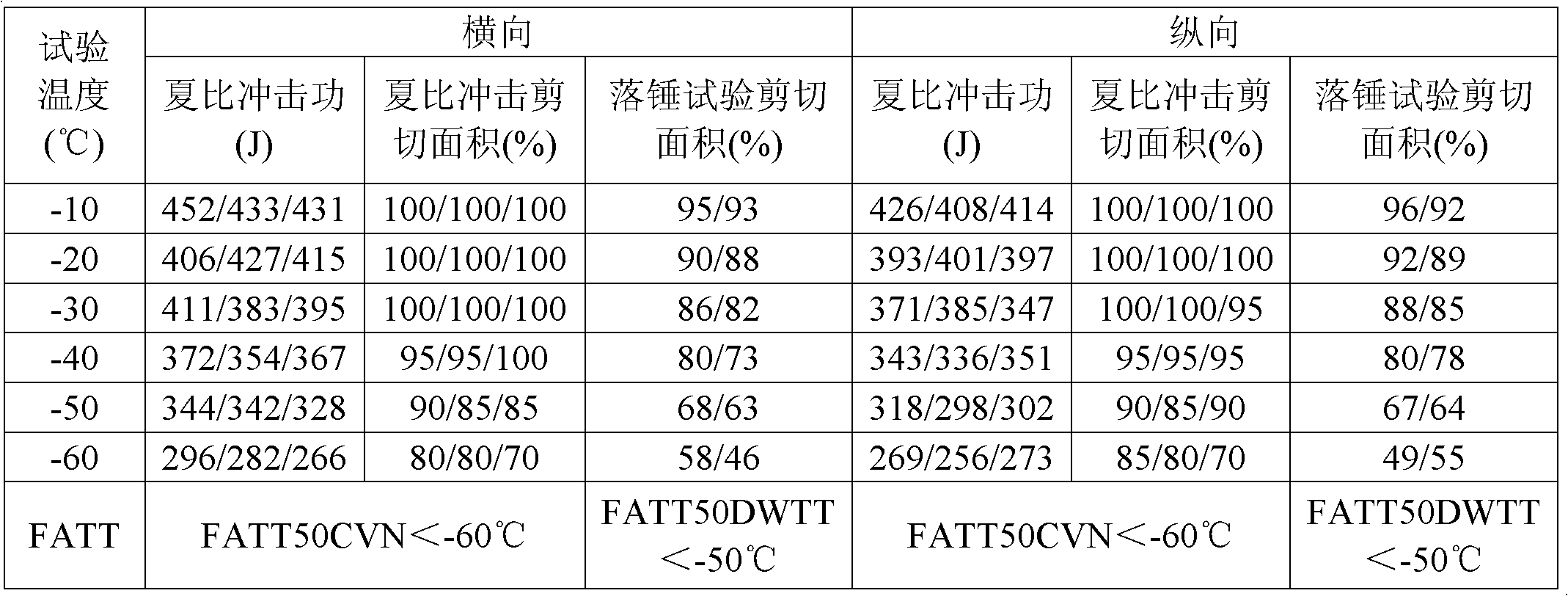

[0028] Table 3 Strength properties of steel plates

[0029]...

Embodiment 2

[0033] According to the production method of X70 hot-rolled medium and heavy plates for submarine pipelines of the present invention, a steel plate with a thickness of 30 mm is produced on a 4300 mm double-frame wide and heavy plate production line by using a 400 mm thick steel billet. The chemical composition of the billet is shown in Table 5, the controlled rolling and controlled cooling process is shown in Table 6, the strength properties are shown in Table 7, and the impact toughness of the steel plate at a series of temperatures is shown in Table 8.

[0034] The chemical composition (weight, %) of table 5 embodiment 2

[0035] C

Si

mn

P

S

Alt

Nb

Ti

Mo

Ni

Cr

Cu

0.054

0.22

1.65

0.008

0.0018

0.037

0.053

0.012

0.23

0.21

0.20

0.22

[0036] Table 6 Process system

[0037]

[0038] Table 7 Strength properties of steel plates

[0039]...

Embodiment 3

[0043] According to the production method of X70 hot-rolled medium and heavy plates for submarine pipelines of the present invention, a steel plate with a thickness of 35 mm is produced on a 4300 mm double-frame wide and heavy plate production line by using a 400 mm thick steel billet. The chemical composition of the billet is shown in Table 9, the controlled rolling and controlled cooling process is shown in Table 10, the strength properties are shown in Table 11, and the impact toughness of the steel plate at a series of temperatures is shown in Table 12.

[0044] The chemical composition (weight, %) of table 9 embodiment 3

[0045] C

Si

mn

P

S

Alt

Nb

Ti

Mo

Ni

Cr

Cu

0.05

0.23

1.70

0.006

0.0013

0.03

0.065

0.015

0.28

0.23

0.20

0.20

[0046] Table 10 Process system

[0047]

[0048]

[0049] Table 11 Strength properties of steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com