Low-fiber-content high-filler-content sealing pad

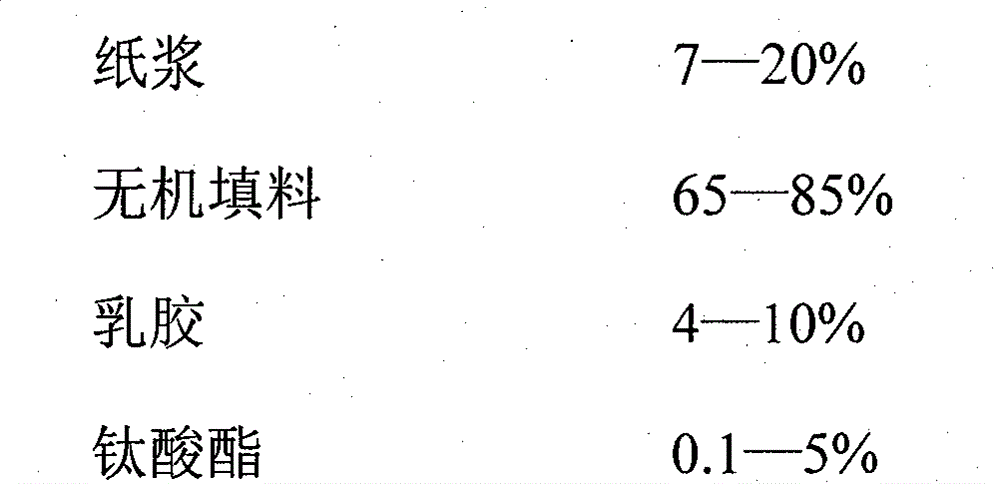

A technology for sealing gaskets and inorganic fillers, which is used in the processing of fiber raw materials, the addition of non-polymer organic compounds, and the synthesis of cellulose/non-cellulose material pulp/paper. The problem of high raw material prices, to achieve the effect of good liquid resistance, simple formula, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

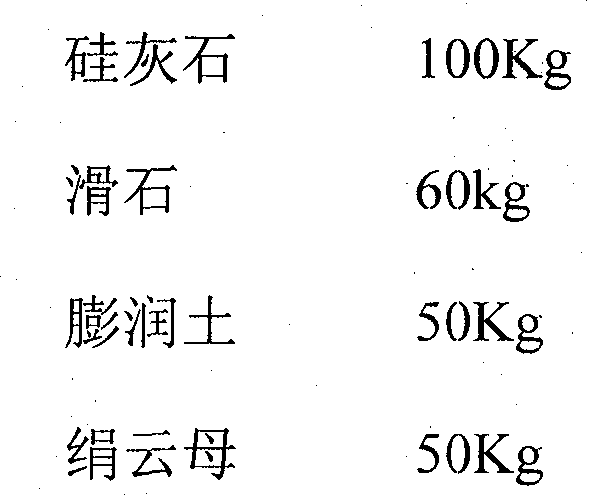

[0029] Embodiment 1: take by weighing respectively

[0030]

[0031] Add 1000Kg 3.2% concentration of pulp suspension, then add 6Kg carbon black, 1.2Kg zinc oxide, 1.2Kg sulfur, 0.8Kg accelerator TMTD, 0.4Kg anti-aging agent D pre-ground slurry, stir evenly , add 45Kg of latex with 40% solid content while stirring; add 15Kg of titanate, stir and mix, add water to dilute to make a slurry with a concentration of 2.5%, take it out by paper machine, dehydrate, dry, calender and vulcanize at 130°C, Made of low fiber high filler gasket.

Embodiment 2

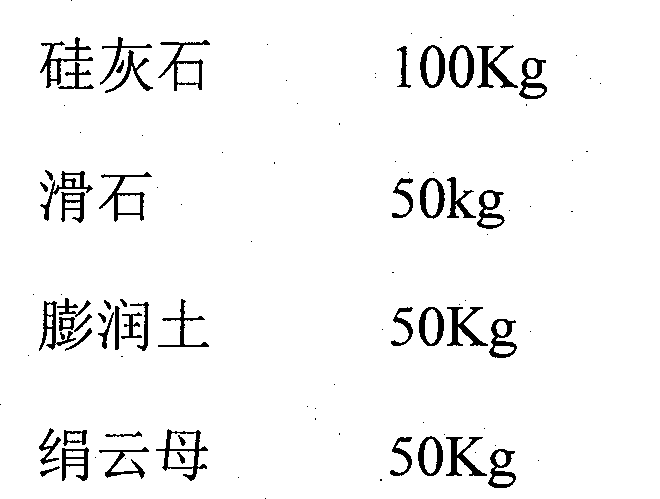

[0032] Embodiment 2: take by weighing respectively

[0033]

[0034]Add 1400Kg 3.2% concentration of pulp suspension, then add 4Kg carbon black, 1.2Kg zinc oxide, 1.2Kg sulfur, 0.8Kg accelerator TMTD, 0.4Kg anti-aging agent D pre-ground slurry, stir evenly , add 35Kg of latex with 40% solid content while stirring; add 12Kg of titanate, stir and mix, add water to dilute to make a slurry with a concentration of 2.5%, take it out by paper machine, dehydrate, dry, calender and vulcanize at 130°C, Low-fiber high-fill gasket

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com