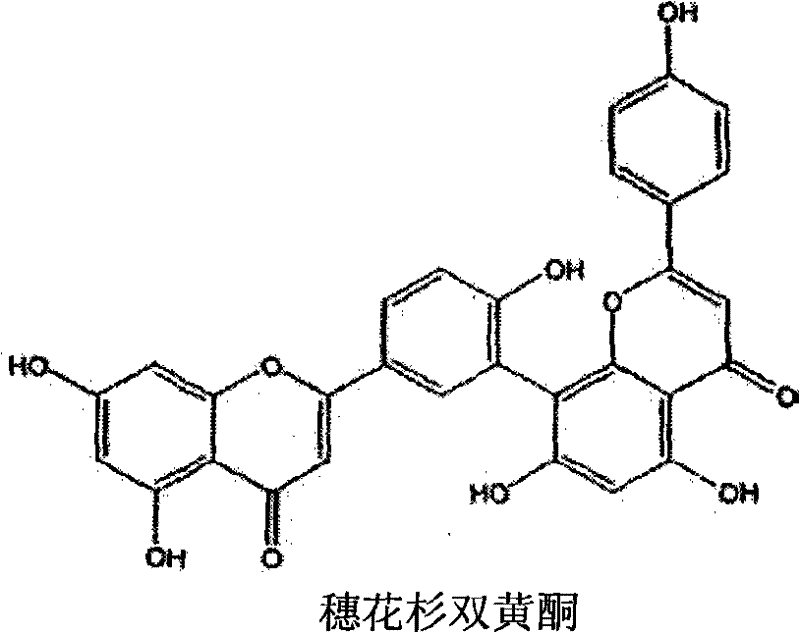

Method for supercritical fluid extraction of amentoflavone

A technology of double flavone and supercritical fluid is applied in bulk chemical production, organic chemistry and other directions, can solve the problems of low extraction rate, large amount of organic solvent, complicated steps, etc., and achieves low extraction temperature, short production cycle, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The dried Selaginella is crushed into a coarse powder, and 2 kg is put into an extraction kettle for supercritical CO 2 Fluid extraction. Extraction conditions: Heat the extraction tank to 37°C, and the analysis tanks I and II to 20°C through a heat exchanger. CO cooling by refrigeration equipment 2 storage tank, open CO 2 Steel cylinder, the flow rate is 30L / h, turn on the booster pump to increase the pressure of the extraction kettle to 23MPa, and the pressure of the analysis kettle Ⅰ and Ⅱ to 6MPa, turn off the CO 2 Cylinder valve. Open the cycle, add 100ml of acetone carrier to the carrier storage tank, and then open the valve of the carrier high-pressure pump to pump the carrier into the extraction kettle. After 3 hours of extraction, open the outlets of the analysis kettle Ⅰ and Ⅱ to collect the released extraction things. The extract was dissolved by heating under reflux with 60% ethanol, added polyamide, stirred evenly, dried at low temperature, added to a ...

Embodiment 2

[0021] The dried Selaginella is crushed into a coarse powder, and 2 kg is put into an extraction kettle for supercritical CO 2 Fluid extraction. Extraction conditions: Heat the extraction tank to 45°C, and the analysis tanks I and II to 33°C through a heat exchanger. CO cooling by refrigeration equipment 2 storage tank, open CO 2 Steel cylinder, the flow rate is 26L / h, turn on the booster pump to increase the pressure of the extraction kettle to 33MPa, and the analysis kettle I and II to 8MPa, turn off the CO 2 Cylinder valve. Open the cycle, add 400ml of ethanol carrier to the carrier storage tank, then open the valve of the high-pressure pump of the carrier to pump the carrier into the extraction kettle. After 5 hours of extraction, open the outlets of the analysis kettle Ⅰ and Ⅱ to collect the released extraction thing. The extract was dissolved by heating under reflux with 60% ethanol, added polyamide, stirred evenly, dried at low temperature, added to a pretreated po...

Embodiment 3

[0023] The dry Selaginella is crushed into a coarse powder, and 5 kg is put into an extraction kettle for supercritical CO 2 Fluid extraction. Extraction conditions: heat the extraction tank to 50°C, and the analysis tanks I and II to 40°C through a heat exchanger. CO cooling by refrigeration equipment 2 storage tank, open CO 2 The steel cylinder, the flow rate is 22L / h, turn on the booster pump to increase the pressure of the extraction kettle to 38MPa, and the analysis kettle Ⅰ and Ⅱ to 9MPa, turn off the CO 2 Cylinder valve. Open the cycle, add 1250ml of acetone carrier to the carrier storage tank, and then open the valve of the carrier high-pressure pump to pump the carrier into the extraction kettle. After 4 hours of extraction, open the outlets of the analysis kettle Ⅰ and Ⅱ to collect the released extraction things. The extract was dissolved by heating under reflux with 60% ethanol, added polyamide, stirred evenly, dried at low temperature, added to a pretreated po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com