Extraction method of high quality lingxiang grass purified oil

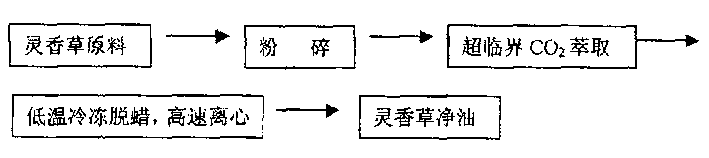

An extraction method, the technology of spirit vanilla, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of difficult extraction of base aroma substances, easy to destroy aroma components, long process flow, etc., achieve low extraction temperature and good industrial application prospects , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Feed amount 10kg, extraction pressure 12MPa, temperature 50°C, time 1h, CO 2 The flow rate is 150L / h; the separation pressure is 5MPa, the separation temperature is 40°C, the freezing temperature is -20°C in the process of freezing and centrifuging to remove wax, and the rotation speed is 4000 rpm, 118g of delica absolute, and the yield of absolute oil is 1.18%. Content 93.5%. Ling vanilla absolute oil has a good aroma, good fluidity, and is yellow and transparent.

Embodiment 2

[0023] Example 2: Feeding amount is 10kg, extraction pressure is 14MPa, extraction temperature is 35°C, extraction time is 1.5h, flow rate is 180L / h, separation pressure is 5.5MPa, separation temperature is 55°C, freezing temperature is -18°C during freezing and centrifugal dewaxing, and the rotation speed is 4500 revs / min, and finally 121g of absolute vanilla absolute, with an absolute yield of 1.21%, and an absolute content of 92.5%. Spirit vanilla absolute oil color is darker than example 1.

Embodiment 3

[0024] Example 3: Feeding amount is 10kg, extraction pressure is 15MPa, extraction temperature is 35°C, extraction time is 1.5h, flow rate is 170L / h, separation pressure is 4.5MPa, separation temperature is 45°C, freezing temperature is -18°C during freezing and centrifugal dewaxing, and the rotation speed is It is 4500 rev / mins, and finally the pure vanilla absolute oil is 125g, and the absolute oil yield is 1.25%, and the absolute oil content is 91.5%. Spirit vanilla absolute oil color is darker than example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com