Thermal-transfer coloured crystal glass and preparation method thereof

A color crystal glass, thermal transfer technology, applied in the direction of copying/marking methods, chemical instruments and methods, printing, etc. problems such as large-scale industrial production, to achieve efficient production and meet performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

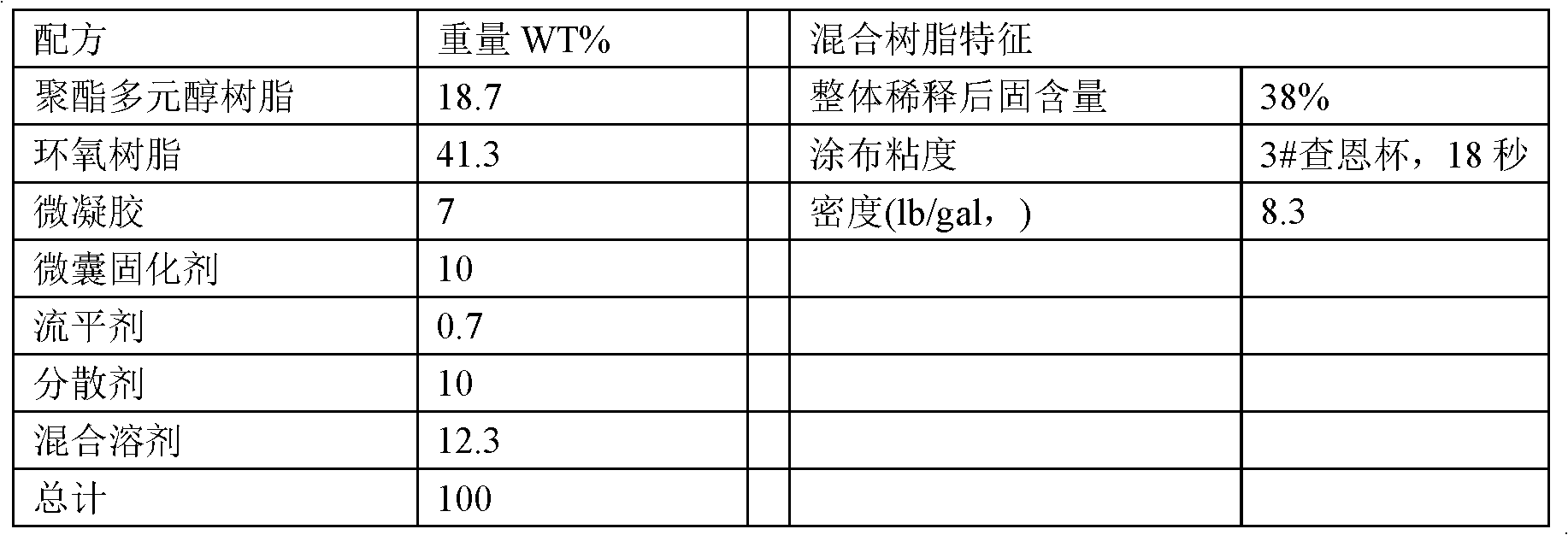

[0028] The following takes the production of thermal transfer color crystal glass as an example for further explanation.

[0029] 1. Production of thermal transfer coating film

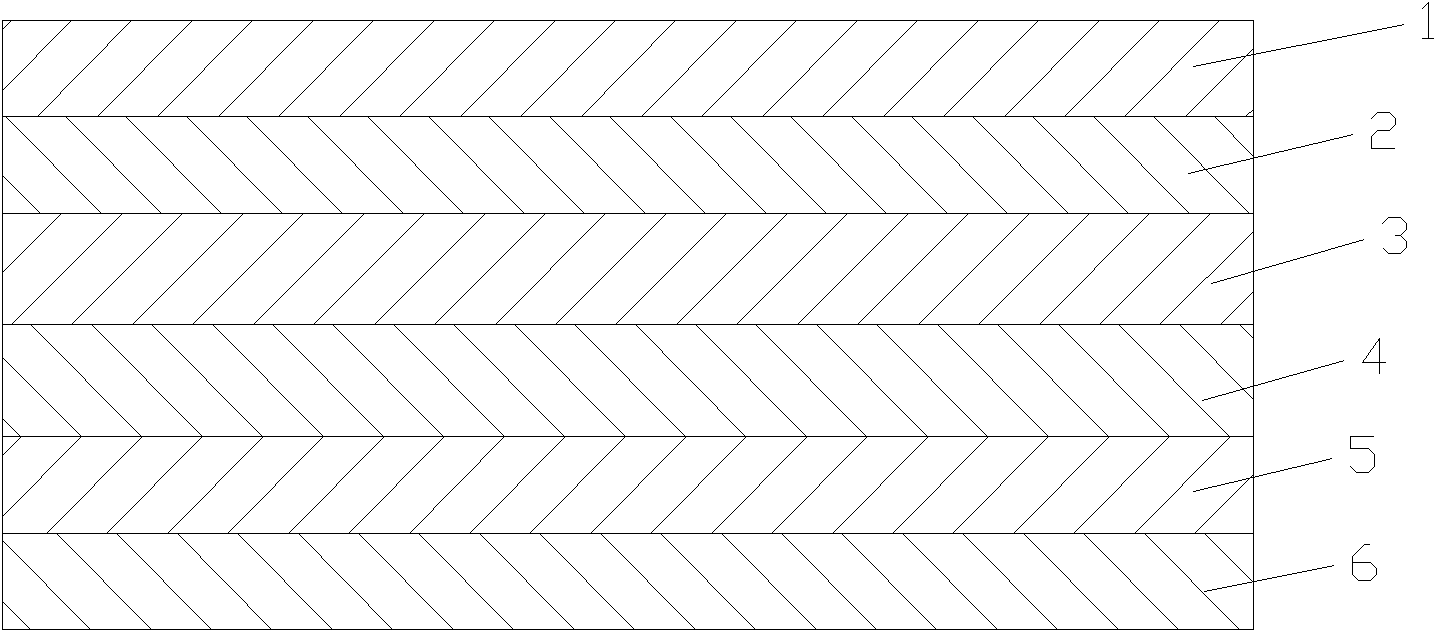

[0030] 1. Select high-quality BOPET film, that is, biaxially oriented polyester film 1 (see figure 1 ), this case uses Dupont 25um BOPET film, which requires single-sided corona treatment, and the surface tension is above 48 dynes.

[0031] 2. Dilute the silicone resin with methyl ethyl ketone and toluene (the mass ratio of methyl ethyl ketone and toluene is 1:1), and form a uniform silicone resin coating 2 on the surface of BOPET by micro-coating, solidify by high-temperature crystallization, and dry Set the temperature profile and fully remove the solvent. When curing, it meets the crystallization point temperature of 180°C, and it takes about 6 seconds to completely cure.

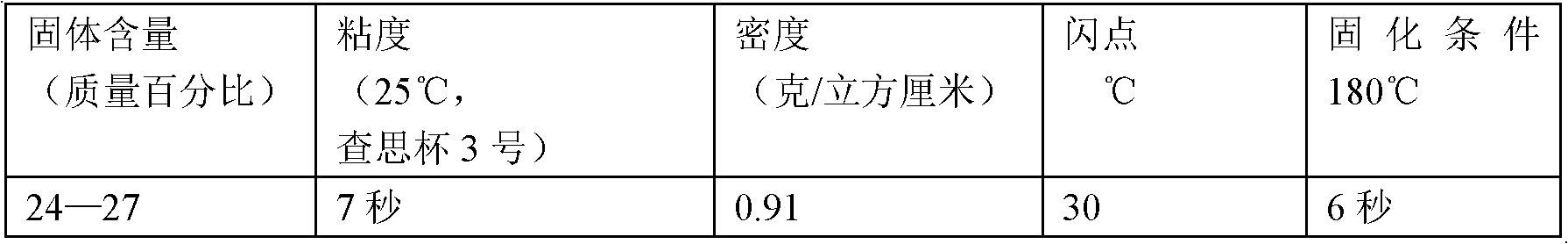

[0032] The typical physical properties of silicone resin diluted with methyl ethyl ketone and toluene are shown in Table 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com