Screen printing stencil and method for imaging it

A printing screen and imaging technology, which is applied in printing, printing machines, printing processes, etc., can solve the problems of low stability and expensive manufacturing of fine mesh screen materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

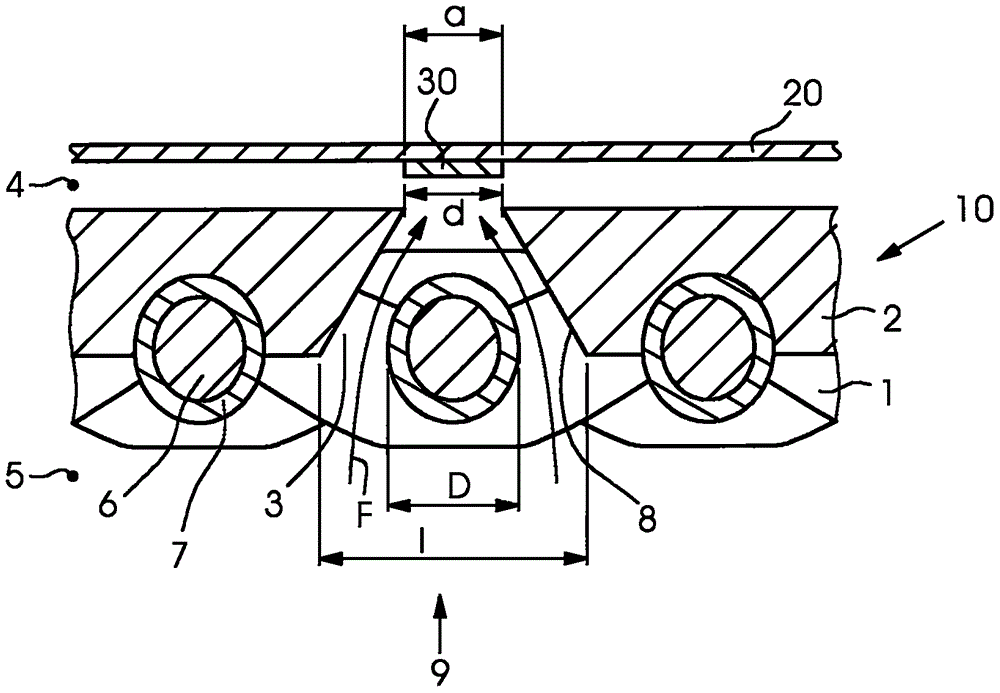

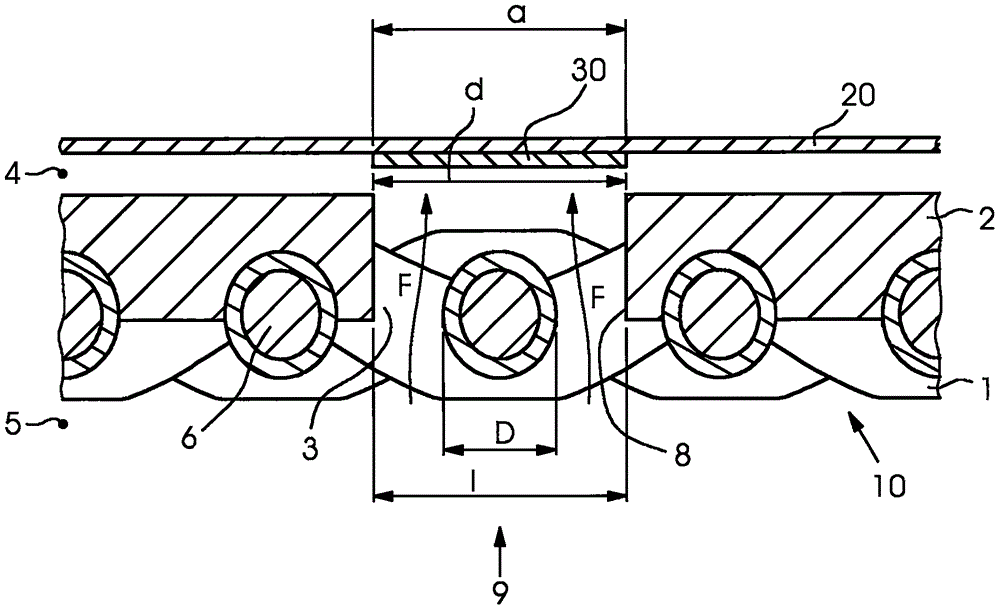

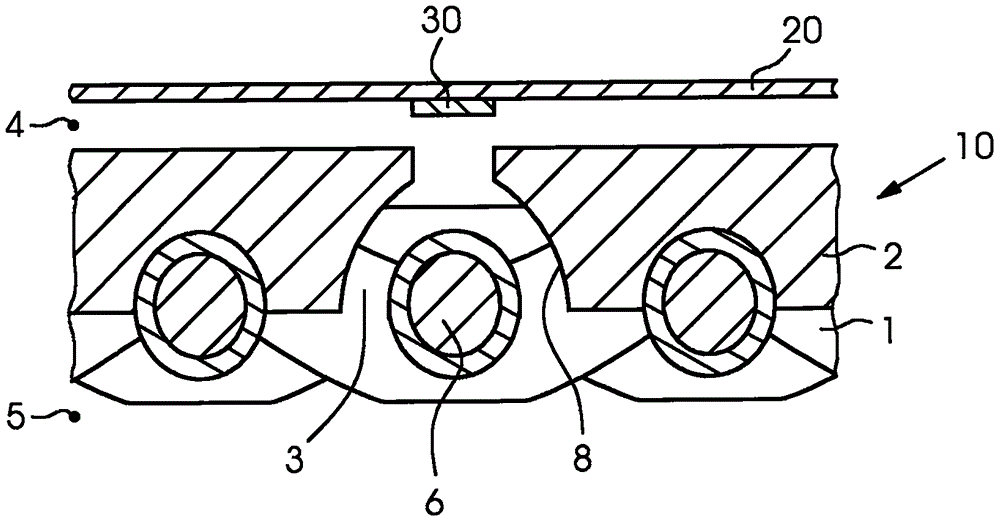

[0040] Figure 6 A flat screen material 10 with a fabric layer 1 according to the prior art is shown. On one side, the screen material 10 has a photopolymer coating 2 (direct stencil). In an alternative embodiment not shown, an imaged film may be applied to the screen structure 10 (indirect stencil). The nickel-plated flat screen material 10 consists of a fabric 1 . Different forms of fabric, also called fabric types, are possible.

[0041] This type of screen material 10 and the printing screen 10 of the present invention are used in rotary screen printing: Figure 7 A screen 100 is shown comprising a flat screen material 10 formed to create a cylindrical sleeve for rotary screen printing. The mesh material 10 retains its cylindrical shape by end pieces not shown in any detail. A squeegee of an invisible screen printing unit is provided inside the screen 100 to squeeze ink through the screen material 10 . The scrapers may be oriented parallel to the axis of rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com