High-strength fiberboard and manufacturing method thereof

A high-strength fiber and fiber technology, which is applied in the manufacture of high-strength fiberboard and the field of high-strength fiberboard, to achieve the effects of protecting the ecological environment, good social and economic benefits, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

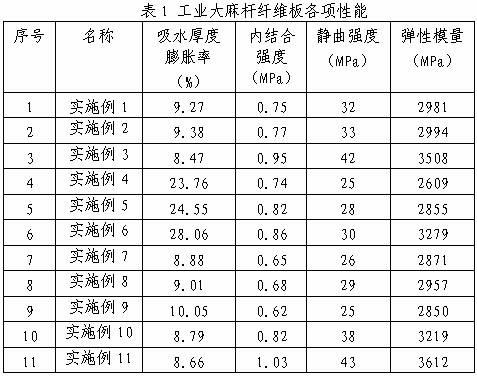

Examples

Embodiment 1

[0021] (1) Raw materials are crushed, and the raw materials of industrial hemp stalks are humidified. After the treatment, the moisture content of the raw materials is 40%, and the industrial hemp stalks are cut by a disc chipper to prepare 1-2 cm in length. In order to reduce the heat grinding difficulty of the phloem and reduce the adverse effects on the wood-based panel vegetation caused by the excessively long phloem, and give full play to the high strength of the bast of industrial hemp stalks, it can strengthen the industrial hemp stalk fiberboard. Using a high-temperature and high-pressure cooker, cook at a temperature of 100° C. for 3.0 h, and then use a disc mill to grind the softened crushed material with a gap of 0.5 mm between the discs to obtain industrial hemp stalk fibers. The fibers are then dehydrated. This breaks through the technical problem that the cortex of industrial hemp stalks has strong toughness and is difficult to prepare qualified fibers, and also ...

Embodiment 2

[0027] Repeat Example 1, with the following differences: the cooking temperature is 110° C., the cooking time is 2 hours, and the gap between the grinding discs is 0.8 mm. The test results are shown in Table 1.

Embodiment 3

[0029] Repeat Example 1, with the following differences: the adhesive used is 10% melamine-modified urea-formaldehyde resin adhesive, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com