Manganese modified molecular sieve type selective catalytic reduction catalyst for diesel engine

A molecular sieve and catalyst technology, applied in the field of diesel engine catalysts, can solve the problems of human health hazards, deviation of high-efficiency temperature window of vanadium-based catalysts, slow driving speed, etc., and achieve the effects of reducing hazards, expanding high-activity temperature window, and improving low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

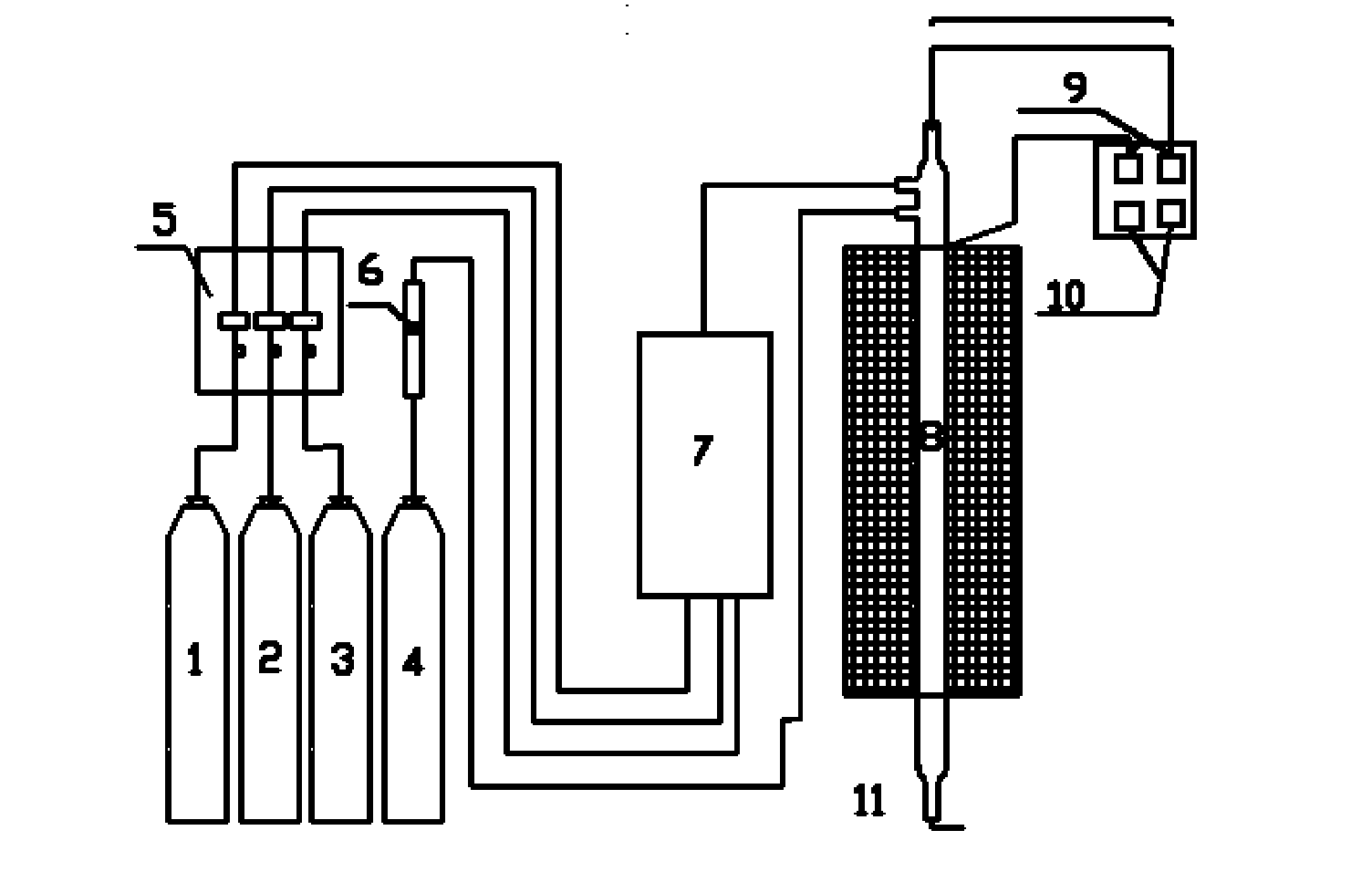

Method used

Image

Examples

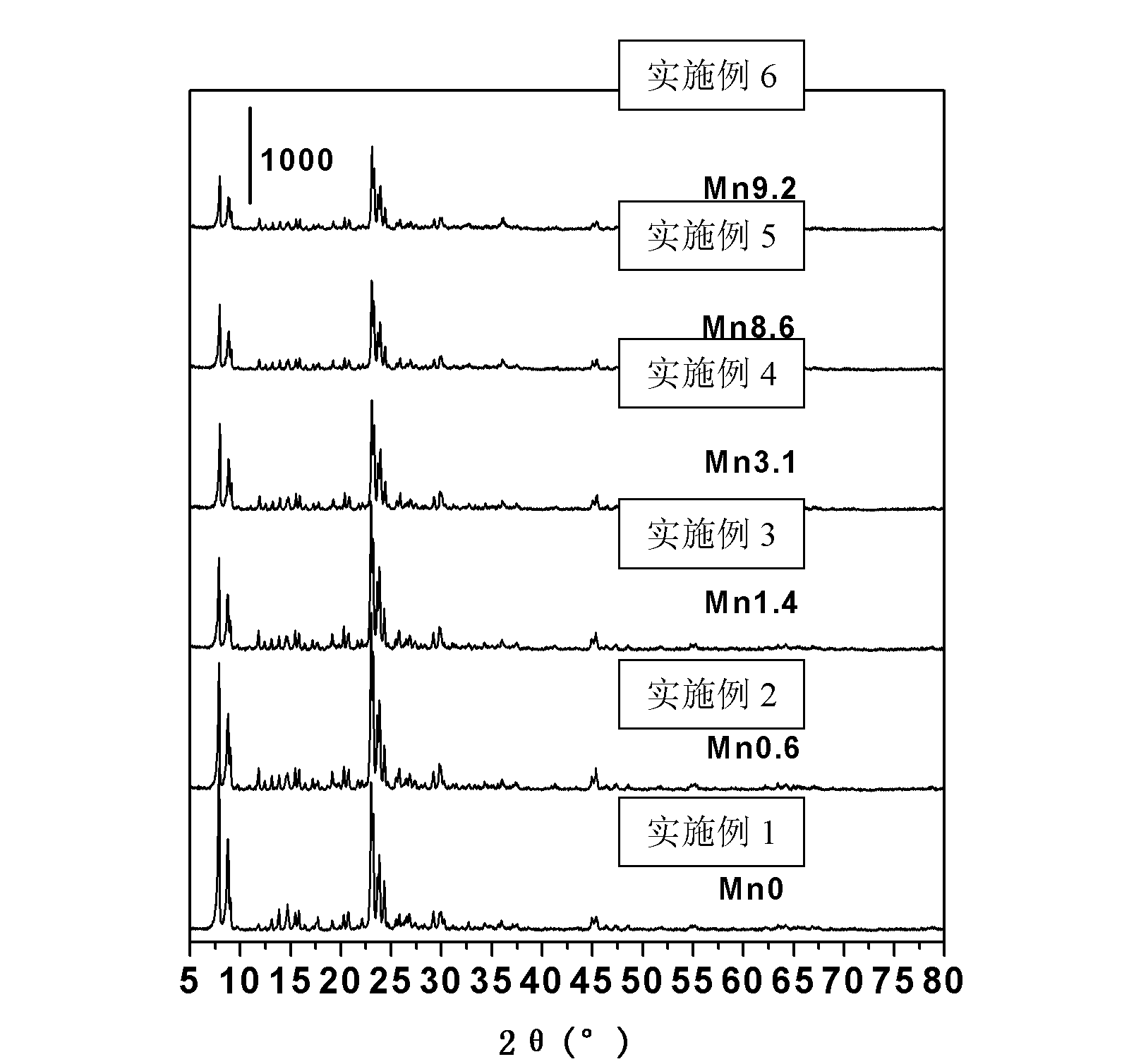

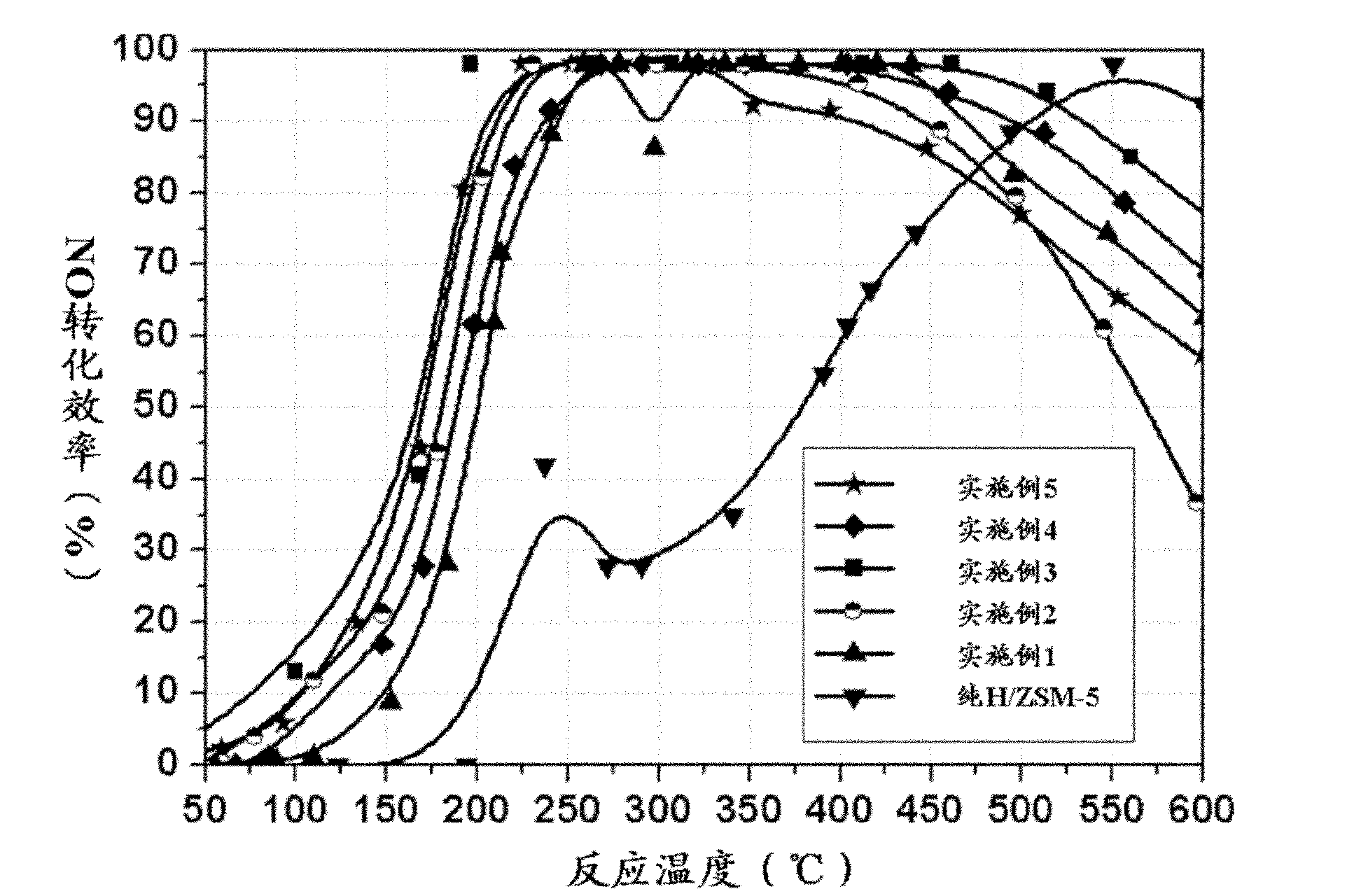

Embodiment 1

[0032] (1) Modification of molecular sieves

[0033] 4.9 g of manganese acetate were dissolved in 200 ml of deionized water. Then weigh 15g of molecular sieve powder with H / ZSM-5 and a silicon-alumina ratio of 16:1 into the manganese acetate solution, and reflux and stir on a water bath at 60° C. for 8 hours to perform ion exchange.

[0034] The reaction mixture after the exchange was completed was filtered, and the filtered solid powder was dried at 80 °C for 12 h, and then calcined at 550 °C for 5 h.

[0035] (2) Preparation of supported catalysts

[0036] It is determined that 5-6% of the coating should be applied on 1kg of the cordierite honeycomb ceramic carrier.

[0037] 20g of γ-Al is required per 100g of modified molecular sieve powder 2 O 3 , 5g pseudo-boehmite, 10g cerium zirconium, 5g polyethylene glycol (average molecular weight 4000) and 50g nitric acid ratio, weigh the powder catalyst, γ-Al 2 O 3 , pseudo-boehmite, cerium zirconium and polyethylene glycol, an...

Embodiment 2

[0044] (1) Modification of molecular sieves

[0045] 9.2 g of manganese acetate were dissolved in 200 ml of deionized water. Then weigh 15g of molecular sieve powder with H / ZSM-5 and a silicon-alumina ratio of 16:1, add it to the manganese acetate solution, and reflux and stir on a water bath at 75°C for 6h to perform ion exchange.

[0046] The reaction mixture after the exchange was completed was filtered, and the filtered solid powder was dried at 100 °C for 10 h, and then calcined at 600 °C for 4 h.

[0047] (2) Preparation of supported catalysts

[0048] It is determined that 10-11% of the coating should be applied on 1 kg of the cordierite honeycomb ceramic support.

[0049] 30g of γ-Al is required per 100g of modified molecular sieve powder 2 O 3 , 8g pseudoboehmite, 8g cerium zirconium, 10g polyethylene glycol (average molecular weight 4000) and 50g nitric acid, weigh the modified molecular sieve powder, γ-Al 2 O 3 , pseudo-boehmite, cerium zirconium and polyethyl...

Embodiment 3

[0056] (1) Modification of molecular sieves

[0057] 36.764 g of manganese acetate were dissolved in 200 ml of deionized water. Then weigh 15g of molecular sieve powder with H / ZSM-5 and a silicon-alumina ratio of 16:1, add it to the manganese acetate solution, and reflux and stir on a water bath at 90°C for 4 hours to perform ion exchange.

[0058] The reaction mixture after the exchange was completed was filtered, and the filtered solid powder was dried at 100 °C for 10 h, and then calcined at 600 °C for 4 h.

[0059] (2) Preparation of supported catalysts

[0060] It is determined that 9-10% of the coating should be applied on 1kg of the cordierite honeycomb ceramic support.

[0061] 20g of γ-Al is required per 100g of modified molecular sieve powder 2 O 3 , 5g pseudoboehmite, 5g cerium zirconium, 5g polyethylene glycol (average molecular weight 4000) and 50g nitric acid ratio, weigh the modified molecular sieve powder, γ-Al 2 O 3 , pseudo-boehmite, cerium zirconium an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com