Preparation of indium-tin oxide/PDMS(polydimethylsiloxane) resin conducting material based on textile template

A technology of indium tin oxide and conductive materials, which is applied in the direction of oxide conductors, conductive layers on insulating carriers, circuits, etc., can solve the problems that there are no research reports on indium tin oxide/PDMS resin composite flexible conductive materials, and achieve The effect of good electrical conductivity, excellent electrical conductivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

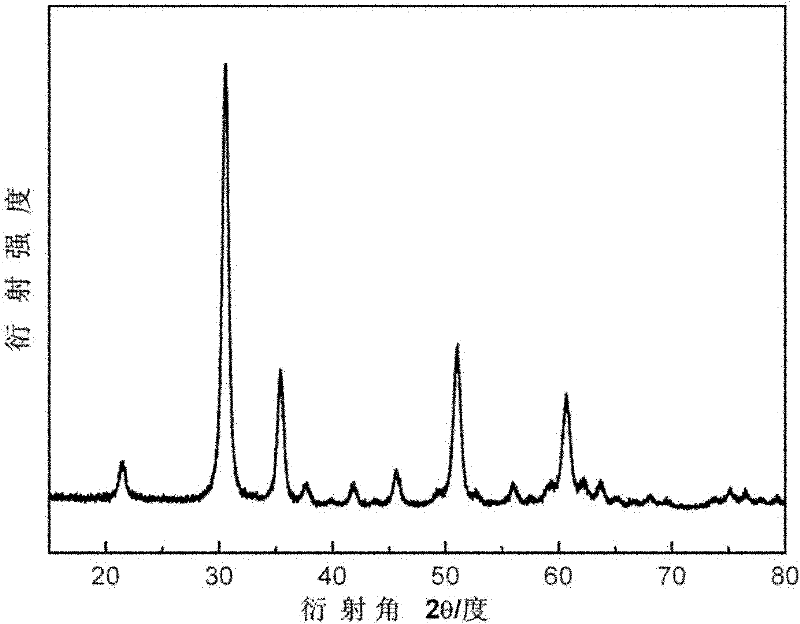

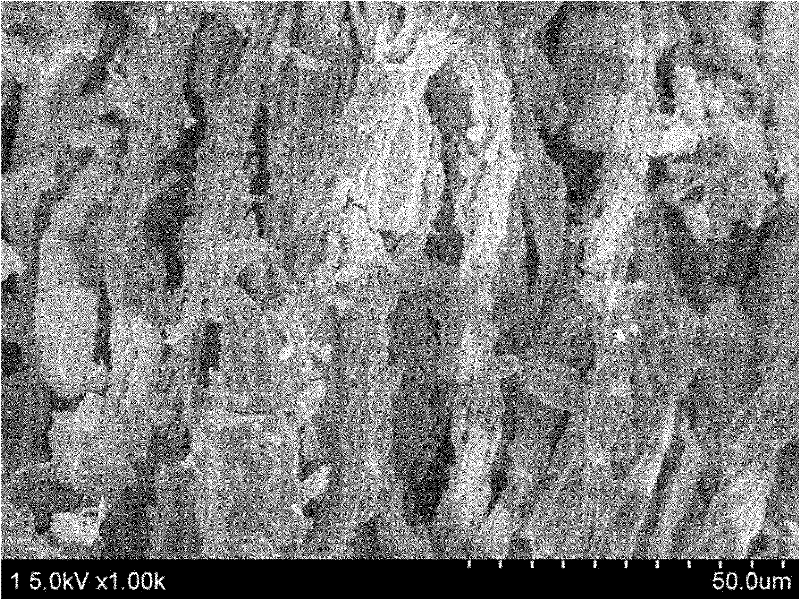

Embodiment 1

[0028] Weigh 0.5330g of indium chloride tetrahydrate and 0.0652g of tin chloride pentahydrate and dissolve them in 15ml of deionized water in a beaker, add NaOH (10wt%) to adjust the pH of the solution to 10.5, mix well, and transfer the reaction solution to the reaction In the kettle, react at 80° C. for 12 hours, cool naturally to room temperature, wash with deionized water and absolute ethanol for 3 times, and obtain an indium tin oxide precursor solution. Put the precursor solution into a Petri dish, and in a vacuum environment with a vacuum pump pressure of 0.08MPa, take 2.5g of cotton cloth and soak it repeatedly and dry it for 3 times, soak for 6 hours each time, dry at 65°C for 20 minutes, and then put it in a muffle Calcining in a furnace at 450° C. for 12 hours to obtain an indium tin oxide conductive material. Mix PDMS and supporting curing agent evenly at a mass ratio of 10:1, then spread the indium tin oxide conductive material on it, and cure it at 120°C for 10 m...

Embodiment 2

[0030] Take by weighing 2.4202g indium chloride tetrahydrate, 0.2980g tin chloride pentahydrate and dissolve in 50ml deionized water in a beaker, add ammonia water (28wt%) to adjust the pH of the solution=8.5, after mixing evenly, transfer the reaction solution to the reaction In the kettle, react at 60° C. for 15 h, cool down to room temperature naturally, wash repeatedly with deionized water 4 times, and wash repeatedly with absolute ethanol twice to obtain an indium tin oxide precursor solution. Put the precursor solution into a petri dish, and in a vacuum environment with a vacuum pump pressure of 0.1 MPa, take 1.8 g of non-woven fabrics and soak them repeatedly and dry them for 3 times, each soaking for 4 hours, drying at 80°C for 20 minutes, and then Calcining at 500° C. for 10 h in a muffle furnace to obtain an indium tin oxide conductive material. Mix PDMS and the supporting curing agent evenly at a mass ratio of 10:1, then spread the indium tin oxide conductive materi...

Embodiment 3

[0032]Take by weighing 1.9127g indium chloride tetrahydrate, 0.2632g tin chloride pentahydrate and dissolve in 40ml deionized water in a beaker, add NaOH (30wt%) to adjust the pH of the solution=11, after mixing evenly, transfer the reaction solution to the reaction In the kettle, react at 90°C for 8 hours, cool naturally to room temperature, wash repeatedly with deionized water 8 times, and wash repeatedly with absolute ethanol twice to obtain an indium tin oxide precursor solution. Put the precursor solution into a Petri dish, and in a vacuum environment with a vacuum pump pressure of 0.07MPa, take 2.1g of non-woven fabric and soak it repeatedly and dry it twice, soak for 6 hours each time, dry at 50°C for 40 minutes, and then Calcining at 550° C. for 10 h in a muffle furnace to obtain an indium tin oxide conductive material. Mix PDMS and supporting curing agent evenly at a mass ratio of 10:1, then spread the indium tin oxide conductive material on it, and cure it at 110°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com