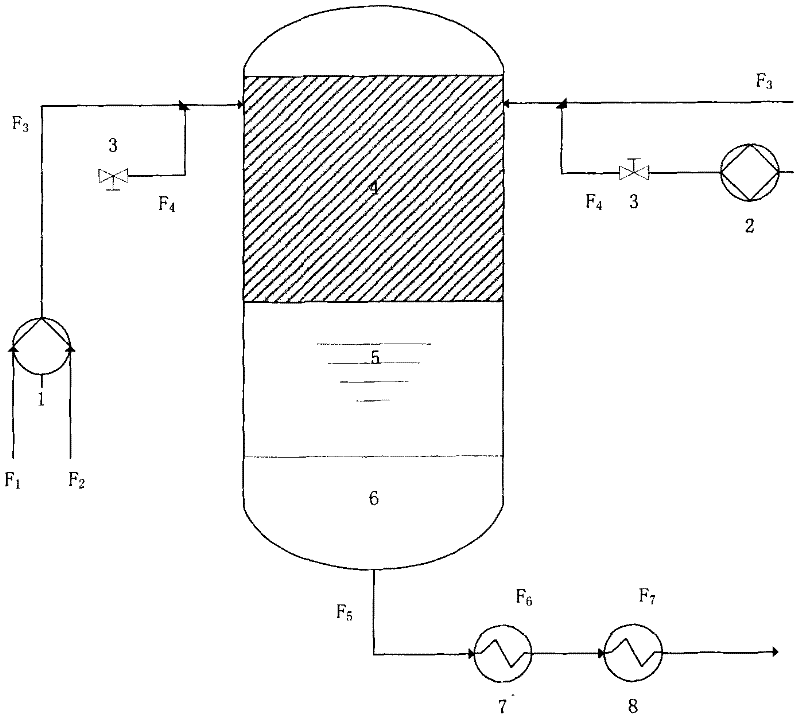

Soft measurement method for fire box temperature of multi-nozzle opposed coal water slurry gasification furnace

A technology of furnace temperature and coal-water slurry, which is applied in the fields of energy industry and chemical engineering, can solve the problems of difficult real-time detection bottlenecks, short working life of high-temperature thermocouples of temperature measuring elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

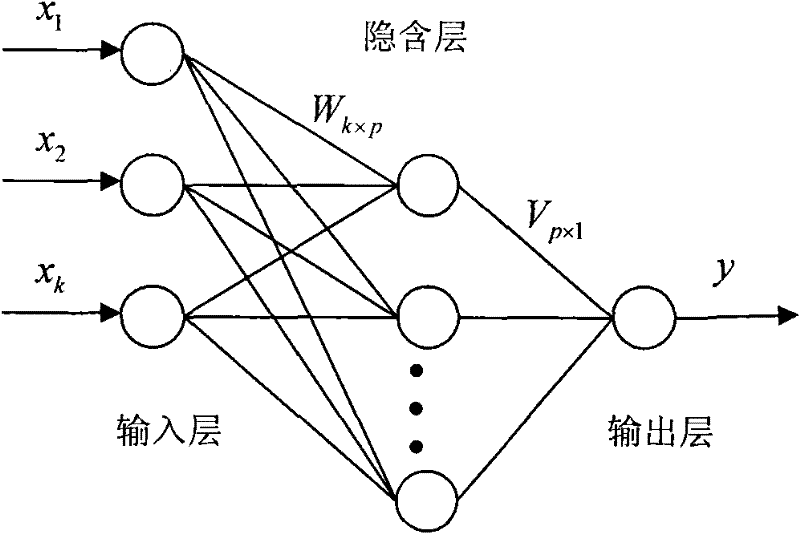

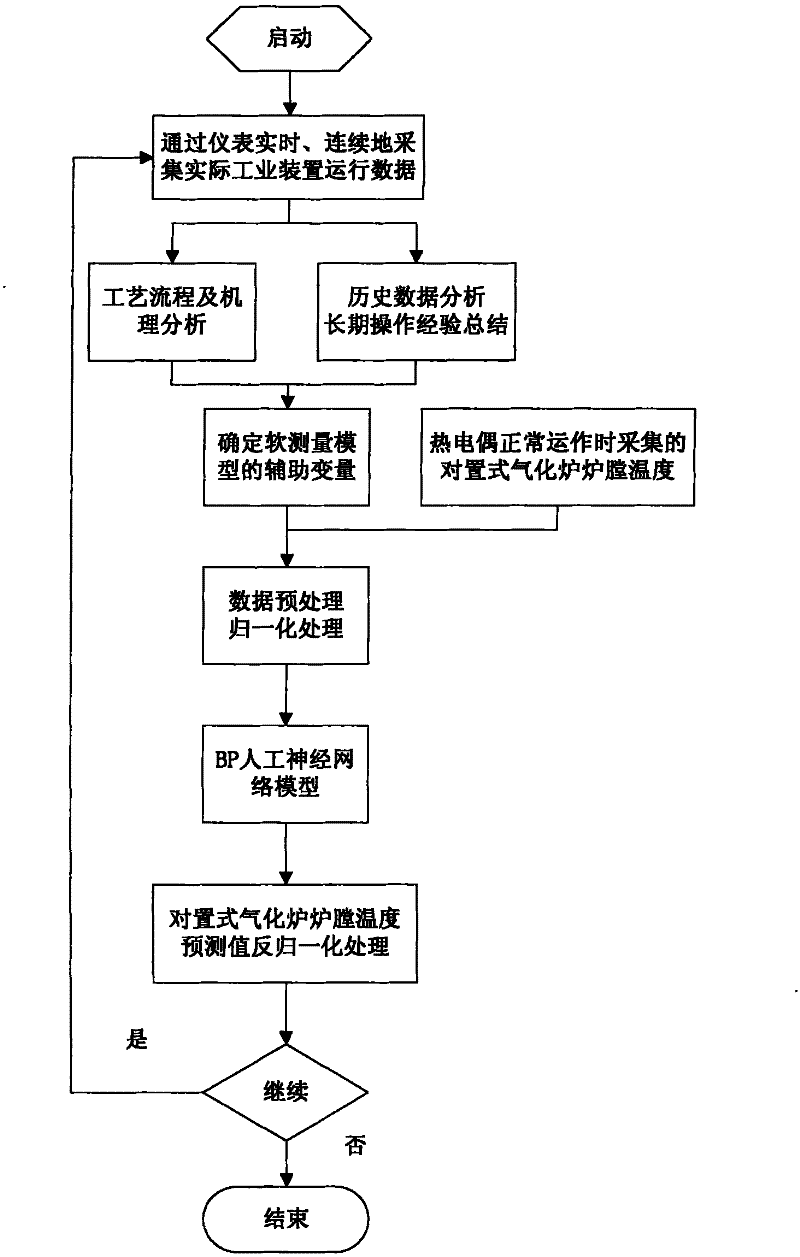

Method used

Image

Examples

Embodiment

[0109] In July 2010, a multi-nozzle opposed coal-water slurry gasifier (such as the device shown in the patent No. 200520047515.3) for nearly 270 hours of operation results of the soft sensor model is as follows Figure 4 shown. The solid line in the figure is the actual measurement data, and the dotted line is the prediction result of the soft sensor model, and the data interval is one hour. Compared with the actual measurement results, the maximum absolute error of the prediction results of the furnace temperature soft sensor model is 4.97%, and the relative error is less than ±5%. Within the allowable range of the error, the accuracy of the prediction results can be guaranteed, and the performance in trend prediction higher accuracy rate.

[0110] In August 2010, the multi-nozzle opposed coal-water slurry gasifier (such as the device shown in the patent number 200520047515.3) has four feeds: the median value of the coal slurry entering the furnace is: 12.5m3 / h, 12m3 / h, 12m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com