Manufacturing method of nickel hydrazine nitrate-minium silicon series igniting powder

A technology for the manufacture of nickel hydrazine nitrate, which is applied in the direction of explosives, etc., can solve the problems of high friction sensitivity and mechanical sensitivity, and unfavorable electric detonator safety, and achieve the effects of long-term storage, environmental protection, and low mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

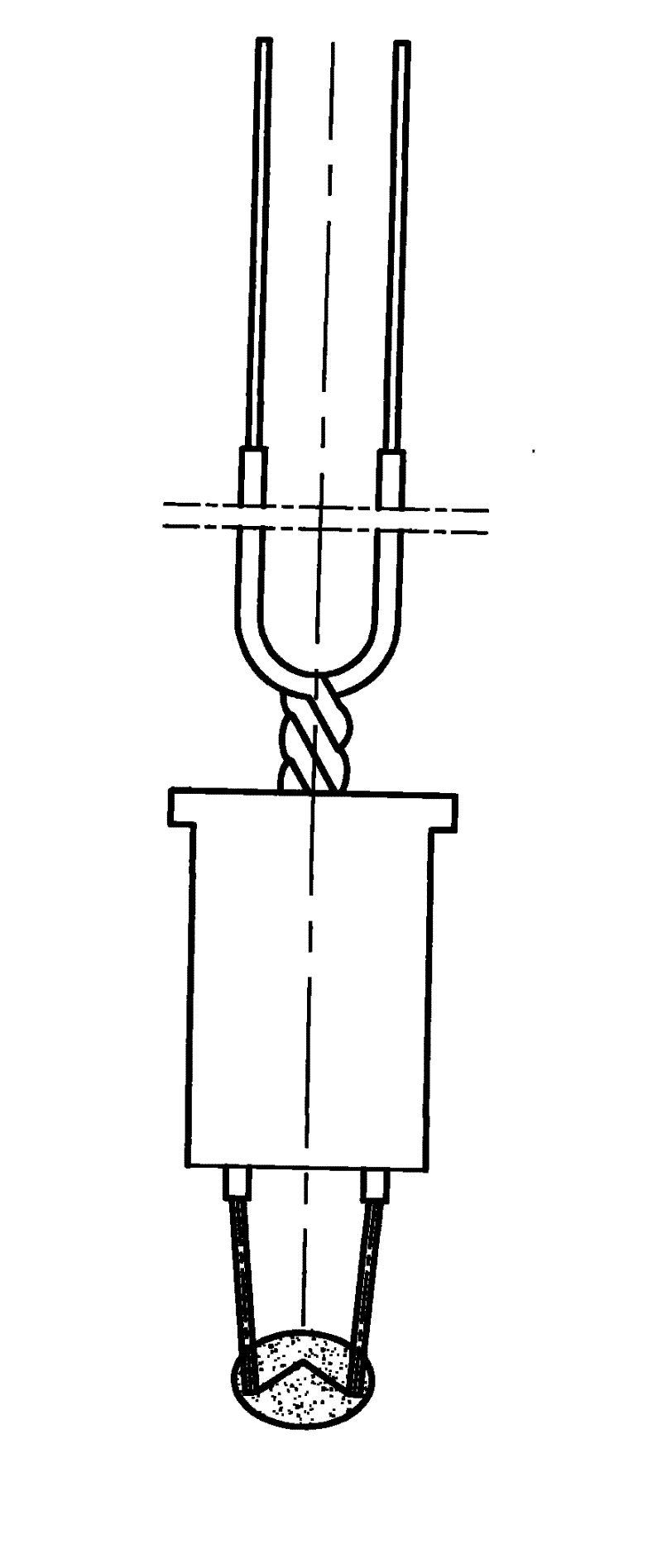

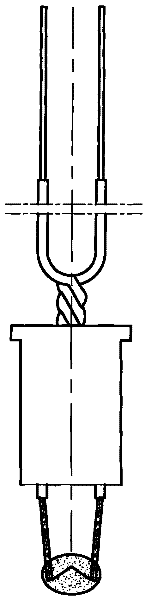

Image

Examples

Embodiment Construction

[0011] The ignition powder of the present invention includes red lead-ferrosilicon, and is characterized in that: the base material of the ignition powder is calculated on a weight basis of 100 grams, and its proportioning ratio is: 85-92 grams of nickel hydrazine nitrate, 8-15 grams of red lead-ferrosilicon, wherein nitric acid The false specific gravity of nickel hydrazine is 0.75~1.10 g / cm 3 , the water content is less than 0.1%, the ratio of red lead-ferrosilicon to lead red and ferrosilicon is 75%:25%; evenly mix nickel hydrazine nitrate, lead red-ferrosilicon, and then measure the main component to be polyvinyl alcohol 15ml of polyvinyl alcohol aqueous solution with a concentration of 8-10% is mixed with the base drug evenly and stirred to produce viscous ignition powder.

[0012] Because nickel hydrazine nitrate does not react with metals such as copper and iron, it has good anti-corrosion performance; and nickel hydrazine nitrate has good flame sensitivity and low mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com