Method for preparing neodymium-doped yttrium aluminum garnet micro/nano powder by spray freeze-drying

A technology of spray freeze-drying and yttrium aluminum garnet, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., can solve the problems of high cost, poor powder dispersibility, and difficult washing of precursor gel. Achieve the effect of avoiding tediousness, simple steps, and achieving uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Nd:YAG powder was prepared by spray freeze-drying using nitrate as raw material.

[0027] (1) Dissolve aluminum nitrate, yttrium nitrate and neodymium nitrate in deionized water, the cation concentration is 1mol / L, and the ion ratio can be used to obtain the compound Nd 0.03 Y 2.97 Al 5 o 12 , adjust the pH value of the mixed ionic liquid to about 4 with ammonia water.

[0028] (2) Spray the uniformly mixed solution into a refrigerant mixed with liquid nitrogen and liquid ethane at a ratio of 1:2 to produce a frozen product, and vacuum freeze-dry the frozen product at -20°C for more than 20 hours to sublimate the water in the product Disappears, powder looks fluffy due to less sublimation of moisture.

[0029] (3) The fluffy powder obtained in step (2) was quickly put into a tube furnace with an initial temperature of 80°C, and calcined at 800°C for 2 hours under an oxygen atmosphere.

[0030] (4) Through XRD test, the powder is amorphous phase.

Embodiment 2

[0031] Embodiment 2: Same as Embodiment 1, except that the calcination condition is calcination at 850° C. for 2 hours.

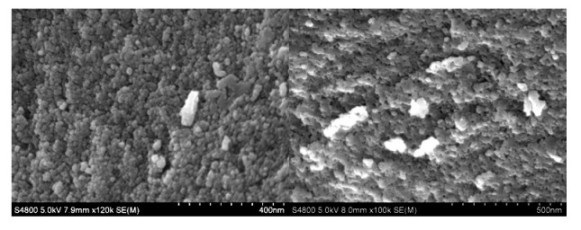

[0032] The results of XRD prove that the Nd:YAG powder obtained under this condition is a pure phase with good crystallinity! SEM showed particles smaller than 20nm (see figure 2 ).

Embodiment 3

[0033] Embodiment 3: Same as Embodiment 1, except that the calcination condition is calcination at 900° C. for 2 hours.

[0034] The results of XRD prove that the Nd:YAG powder obtained under this condition is a pure phase, and the crystallinity is higher than that of the powder calcined at 850°C!

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com