Technique for preparing wollastonite ultrafine powder from calcium silicate hydrate

A technology of hydrated calcium silicate and ultrafine powder, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve the problems of high production cost and application fields, and achieve a wide range of uses, low energy consumption, and reduced processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

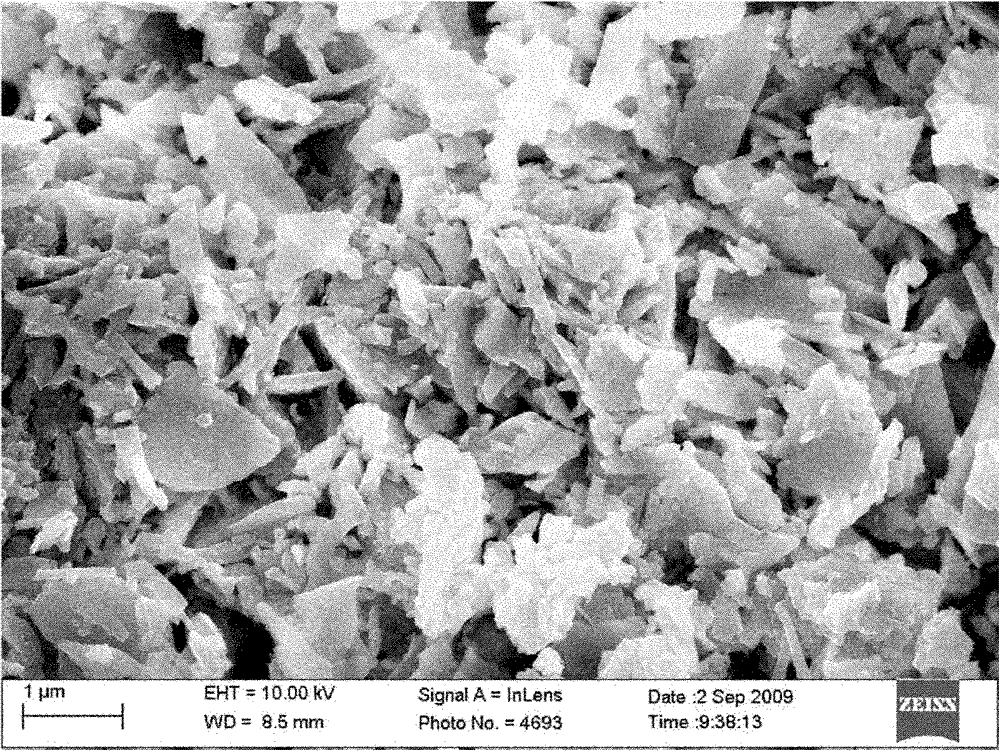

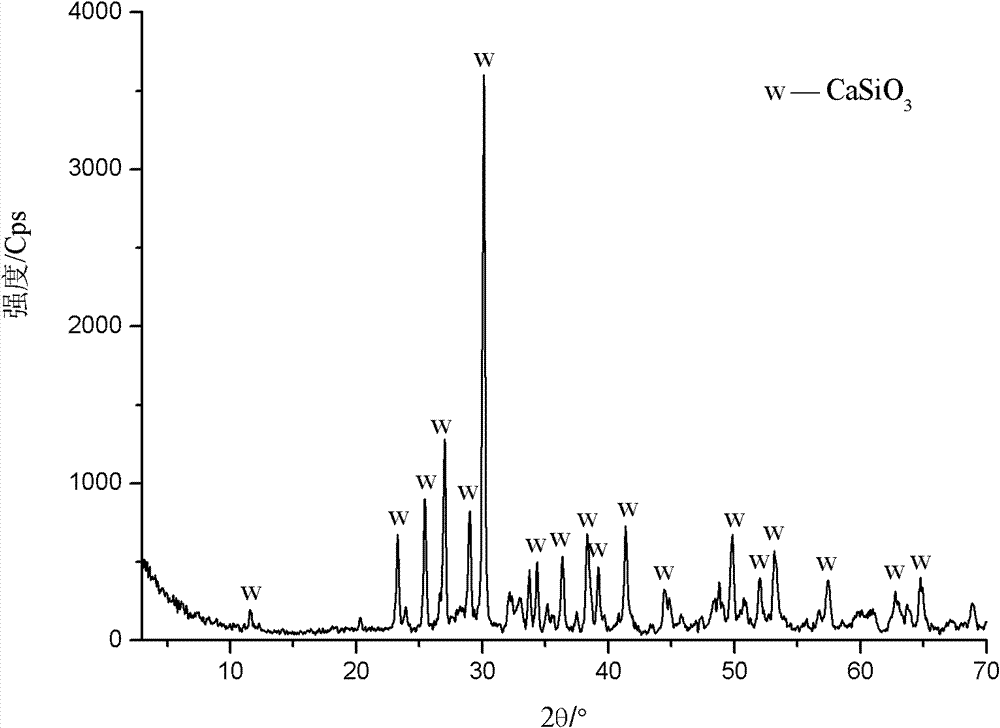

Image

Examples

Embodiment 1

[0030] The chemical composition analysis results of calcium silicate hydrate (CSH-1) are as follows:

[0031]

[0032] Accurately weigh 4.3g of sodium thiosulfate and 5.9g of oxalic acid, fully dissolve them in 1L of distilled water, and make impurity removal solution (CTY-1) for later use. Weigh 100g of calcium silicate hydrate (CSH-1) and add it to 500mL impurity removal solution (CTY-1) that has been heated to 80°C, and stir and react at this temperature for 60min; after the reaction, the slurry is filtered and washed to obtain 278g The impurity-removing filter cake of calcium silicate hydrate with a moisture content of 64%; the impurity-removing filter cake of calcium silicate hydrate was dried at 150° C. for 120 min in an electric blast drying oven to obtain 102 g of calcium silicate hydrate-removing powder; The impurity-removing powder of calcium silicate hydrate was put into an alumina crucible, calcined in a muffle furnace at 930°C for 60 minutes, and cooled to room...

Embodiment 2

[0034] The chemical composition analysis results of calcium silicate hydrate (CSH-2) are as follows:

[0035]

[0036] Accurately weigh 5.7g of sodium thiosulfate and 1.5g of oxalic acid, fully dissolve them in 1L of distilled water, and make impurity removal solution (CTY-2) for later use. Weigh 100g of calcium silicate hydrate (CSH-2) and add it to 700mL impurity removal solution (CTY-2) that has been heated to 60°C, and stir and react at this temperature for 90min; after the reaction, the slurry is filtered and washed to obtain 194g Hydrated calcium silicate impurity-removing filter cake with a moisture content of 50%; the hydrated calcium silicate impurity-removing filter cake was dried at 250° C. for 40 minutes in an electric blast high-temperature drying oven to obtain 98 g of hydrated calcium silicate impurity-removing powder; The impurity-removing powder of calcium silicate hydrate was put into an alumina crucible, calcined in a muffle furnace at 850°C for 120min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com