Contact-type advanced recycling system for waste heat of low-temperature flue gas

A low-temperature flue gas, contact technology, applied in direct contact heat exchangers, air heaters, steam condensation, etc., can solve the problems of large volume of flue gas waste heat recovery equipment, small heat transfer temperature difference, and large thermal resistance, etc. To achieve the effect of easy installation and implementation, weakening acid corrosion, and no increase in concentration

Inactive Publication Date: 2011-08-31

TSINGHUA UNIV +1

View PDF8 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The thermal resistance of flue gas on the surface of these heat exchangers is large, and the range of enhanced heat transfer coefficient is K=30~200W / m 2 °C, and the heat transfer temperature difference of the low-temperature flue gas is small, which will inevitably result in a huge volume, high cost and limited application of the flue gas waste heat recovery equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0058] The working process of the system of the second embodiment is basically the same as that of the first embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

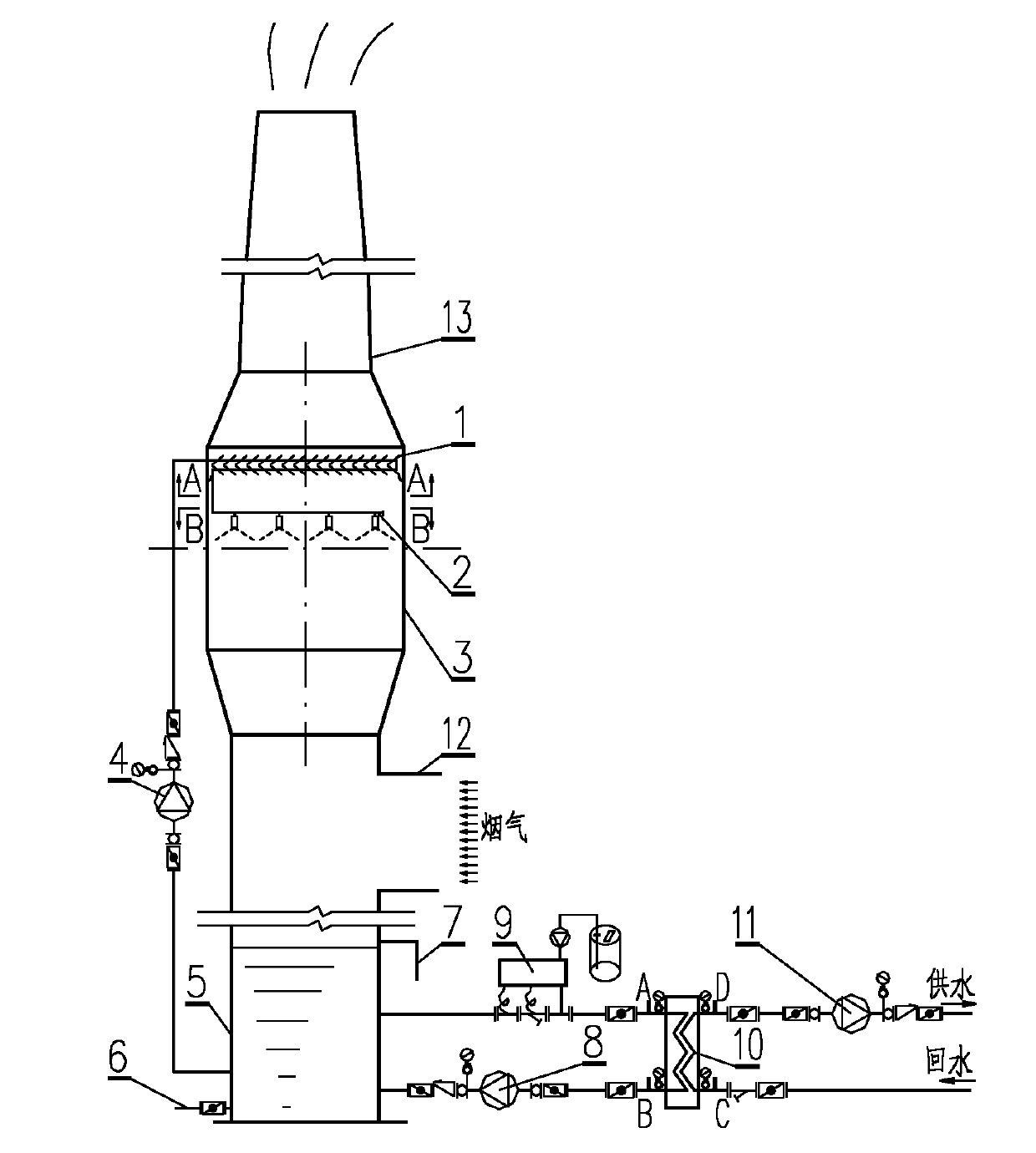

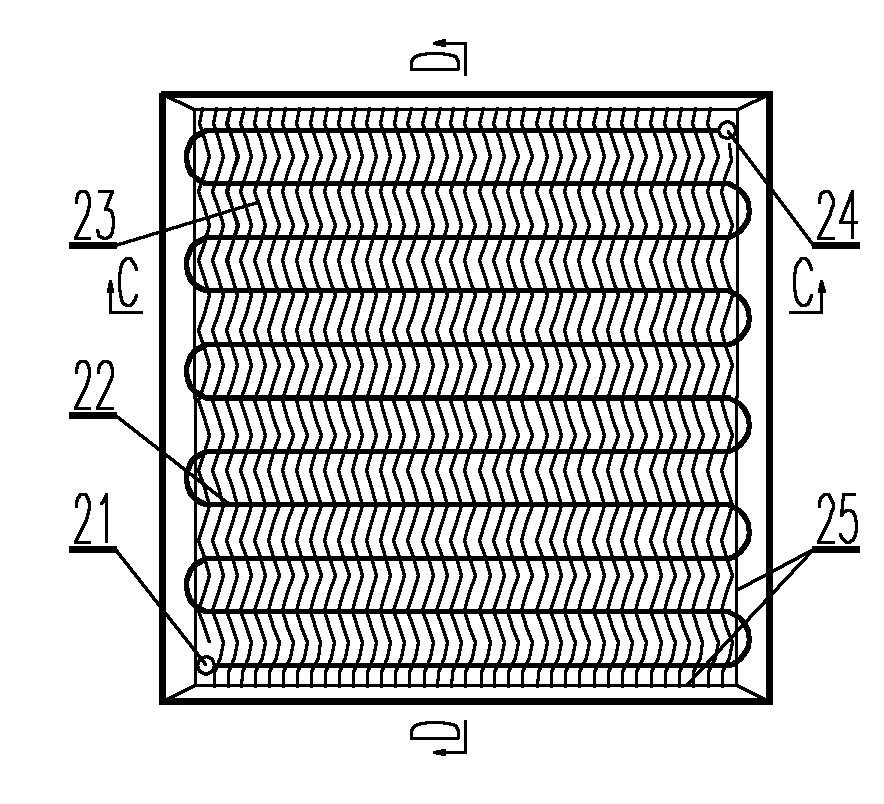

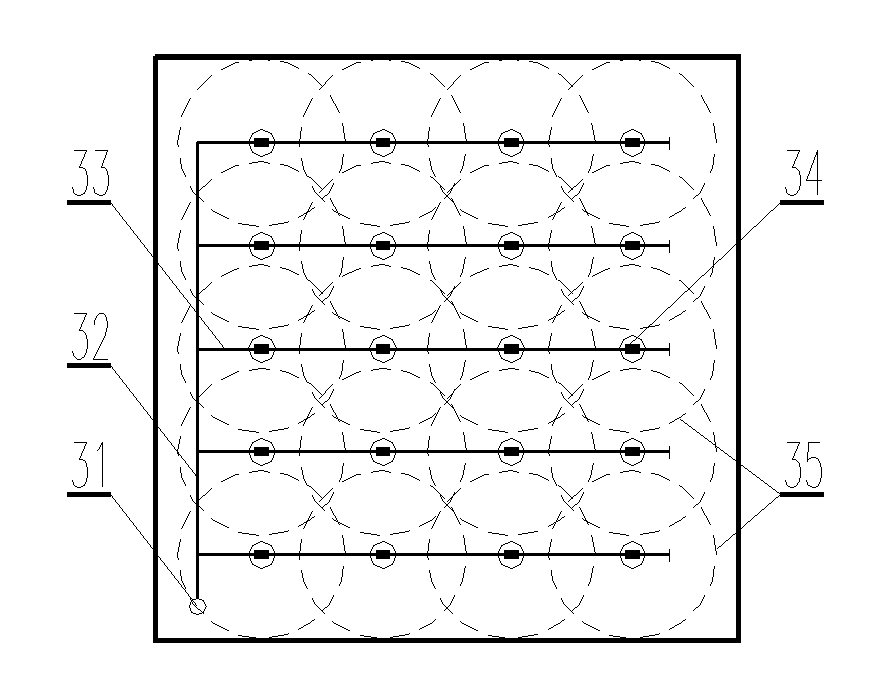

The invention relates to a contact-type advanced recycling system for the waste heat of low-temperature flue gas, and belongs to the technical field of the advanced recycling of the waste heat of the flue gas. The system comprises a contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas, a heat storage and water quality maintaining purification subsystem and a waste heat output utilization subsystem, wherein the contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas mainly comprises a water retaining condenser with a multifunctional fin, a water distributor, a contact-type spray tower and a spray pump; the heat storage and water quality maintaining purification subsystem mainly comprises a hot water sedimentation water storage tank, a drainage pipe, an overflow pipe, a circulating pump and an full-automatic water quality measuring control maintainer; and the waste heat output utilization subsystem mainly comprises a plate-type heat exchanger and a water feeding pump. By utilizing the contact-type advanced recycling system, the sensible heat of the flue gas is recovered, and a large amount of water vapor latent heat in liquid and gas fuel flue gas is also recovered; therefore, the contact-type advanced recycling system has the effects of washing and purifying the flue gas and the effects of washing and weakening acid corrosion on equipment and flues.

Description

technical field [0001] The invention belongs to the technical field of deep recovery and utilization of waste heat of flue gas using liquid and gas as fuel, and particularly relates to a direct contact deep recovery and utilization system of waste heat of low-temperature flue gas. Background technique [0002] With the adjustment of China's energy structure, the consumption and proportion of diesel (heavy) oil and natural gas are increasing rapidly. The exhaust gas temperature at the outlet of oil-fired, gas-fired boilers, gas-steam combined cycle, and large internal combustion engine waste heat boilers is generally between 160 and 180°C or higher. At this time, the temperature of the flue gas is low, the energy flow density is small, and it no longer has the ability to work or the economic value of heat utilization. It is a waste energy that has not been fully recycled at this stage. Today, energy issues are increasingly becoming the bottleneck of social and economic devel...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24H8/00F28B5/00F28F25/02B01D5/00B01D47/06B01D53/18

CPCY02B30/102Y02B30/00

Inventor 吴华新张寅平杨晓西邵友元秦贯丰王馨

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com